What is a Smart Ring Battery and The Manufacturing Process?

A smart ring battery (mostly also known as a curved lipo battery) is a small battery designed for smart rings, and they are an important part of wearable electronics. Smart ring batteries are usually made using lithium polymer battery technology because these batteries can be made in the desired shape and size to fit the compact design of the ring. Smart ring batteries are needed to provide smart rings with the necessary power to support functions like health and exercise monitoring, notification alerts, gesture control, and navigation and location tracking.

Fig.1

What are the features of the smart ring battery?

1. High energy density: despite their small size, polymer lithium-ion batteries can provide high energy density, which means they can store more power in a relatively small space.

2. Lightweight and compact: the design of the battery must be coordinated with the overall internal and external structural design of the ring, so they need to be as lightweight and compact as possible.

3. Sufficient battery life: Smart rings usually require batteries to support a longer usage time to avoid frequent charging.

4. Safety: Since batteries are close to the user's skin, they need to meet strict safety standards to prevent overheating, short-circuiting, or other potentially dangerous situations.

Which is better, the smart ring battery stacking process or the winding process?

Curved lipo battery is one of the important components of the smart ring, its performance quality can not only affect the service life and duration of the smart ring but also affect the appearance of the smart ring size and aesthetics. Since this is the case, then the following Grepow will do a comparison of the current electronic smart ring battery process.

The smart ring batteries used now belong to the high energy density lithium batteries, and there are two main production processes: stacking and winding. Let's briefly explore the differences between these two processes of batteries together.

The ring battery made by the stacking process can be more tightly sealed when the battery is molded into an arc, which will not affect the beauty of the battery edges and corners by edge wrinkles, and the battery pole coating will not be damaged due to severe extrusion, which will lead to capacity degradation, internal puncture short-circuiting, and shorter service life, and other consequences.

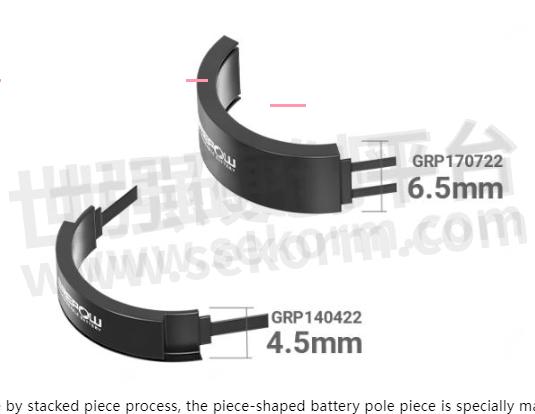

Fig.2

The ring battery is made by stacked piece process, and the piece-shaped battery pole piece is specially made for various shapes, when the battery is made into a curved mold, the sealing edge is tight, the edge wrinkles are close to zero, and the corners of the battery are smooth; what's more important is that the battery will not be damaged due to the extrusion of the pole piece coating, and it will avoid the problems such as capacity degradation, short circuit of the internal puncture and short service life.

Fig.3

Ring batteries using the winding process, as shown above, not only have an unsightly appearance after the bending arc is formed, but the internal structure of the battery is likely to be damaged because of the extrusion caused by the bending. Even if the battery is used normally at first, after some time, it is probable to be squeezed by the greater resistance of the place, resulting in easy heating or pole piece damage, the battery capacity will be greatly attenuated, and the service life is also greatly shortened.

The above is a brief introduction to the "smart ring battery and production process comparison". When selecting ring batteries, manufacturers need to consider the battery life, charge/discharge cycle stability, battery production process, and compatibility with other ring components. In addition, to meet the needs of different markets, battery suppliers need to offer a diverse range of products to suit different designs and technical specifications.

- +1 Like

- Add to Favorites

Recommend

- Smart Ring Battery Supplier and Manufacturer

- SMART Modular Expands DuraMemory™ Offerings with Proprietary DIMM Retention Device for Harsh Operating Environments

- SMART Modular Technologies to Present at SNIA Persistent Memory + Computational Storage Summit

- SMART Modular Announces the SMART Kestral PCIe Optane Memory Add-in-Card to Enable Memory Expansion and Acceleration

- SMART‘s DDR4 Modules Range From 32GB To 4GB, 20% Lower Overall Power Vs. DDR3

- SMART New SSD Solutions Are Ideally-suited for Government and High-security Applications

- SMART Modular Technologies Announces Next Generation of ME2 Flash

- SMART Announces SMART Zefr Memory with Ultra-High Reliability Performance for Demanding Compute Applications

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.