The Applications of PPTC Protection Devices in Wireless Electronic Products, Battery Packs, Chargers, Power Converters and Transformers

PPTC is the abbreviation of Polymeric Positive Temperature Coefficient. PPTC device is a polymer positive temperature coefficient device. This device can protect the circuit when the current surge is too large and the temperature is too high. When used, connect it in series in the circuit. Under normal circumstances, its resistance is very small and its loss is also very small, which does not affect the normal operation of the circuit; but if overcurrent (such as a short circuit) occurs, its temperature rises and it The resistance increases sharply, limiting the current and avoiding damage to the components in the circuit. When the fault is eliminated, the temperature of the PPTC device automatically drops and returns to the low resistance state. Therefore, the PPTC device is also called a resettable fuse.

The following describes the applications of PPTC devices in wireless electronic products, battery packs, chargers, power converters, and transformers.

Protecting circuits in wireless electronic products

Wireless electronic products (such as mobile phones, and PDAs), whether they are directly powered or charged, require an AC/DC power converter to convert the grid voltage or unregulated DC voltage into a lower-level DC voltage. As AC/DC power converter accessories and various universal chargers have entered the market, if an inappropriate AC/DC power converter is selected, its output voltage, current, and polarity may exceed or violate the internal circuit of the electronic product itself. specifications, so it may damage the circuit or even cause safety issues. Given this, circuit protection is even more important.

Commonly used circuit protection methods are to use of disposable fuses or special connectors. Although disposable fuses are relatively cheap, they can only be used once and are prone to malfunctions. If special connectors are used, it usually only takes a few days for other accessory manufacturers to copy the same product. Mating errors will still occur and may cause serious damage, for example, by increasing the breakdown voltage of the component. The output current will cause the device's power consumption to be too high. The emergence of micro PPTC devices with reliable performance provides a good solution for circuit protection of small, lightweight wireless portable products. In addition, most failures in wireless devices are temporary, and using recoverable PPTC protection devices can also avoid costly product warranty costs. Connect the PPTC device in series at the power interface, or connect a voltage-limiting device in parallel, such as a Zener diode, transient voltage suppression diode or voltage overload protector, to avoid the problems caused by mismatched power converters.

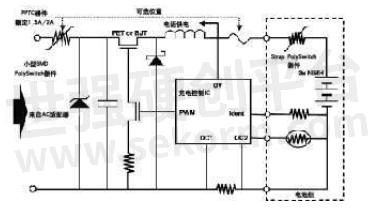

Fig.1

Figure 1 is a typical battery charger circuit. In this circuit, the unregulated DC output voltage of the power converter is modulated by the voltage stabilizing circuit and converted into an appropriate voltage to charge the battery. PPTC devices and voltage overload protection devices work together to protect against the following faults:

(1) Overcurrent: Overcurrent may damage the power FET or battery pack.

(2) Reverse polarity: At this time, the diode is turned on and the PPTC device enters a high impedance state for current limiting protection.

(3) Overvoltage: At this time, the voltage overload protection device works, and the PPTC device limits the current.

(4) The PPTC device can also be installed at the input end of the battery pack to add a layer of protection. If the device is used to power active accessories such as headphones and car hands-free equipment, the power output end also needs protection.

Protect battery pack

Battery overheating caused by overcharging is a major concern for battery pack designers. Although there are overvoltage and overcurrent detection safety protection circuits (including integrated circuits and MOSFETs) in the lithium battery pack, PPTC devices still need to be connected in series. Because semiconductor circuits can malfunction when there is excessive electrostatic discharge, excessive temperature, or short circuit. When the voltage protection circuit fails and there is no temperature protection, the battery will generate excessive heat when overcharged or overcharged, causing the battery to rupture, leak, smoke, or even burn.

In addition, the extension of the working time of portable products has prompted people to develop smaller and lighter lithium-ion and lithium-polymer batteries. In order to adapt to the requirements of these new battery protection circuits, PPTC protection device manufacturers are also making continuous efforts to reduce device consumption.

By connecting the PPTC battery protection device and the original cells in the battery pack in series, whether the temperature rise is caused by a short circuit or overcharging, the device can play a protective role without the need for thermal fuses or bimetal circuit breakers. This strip-shaped PPTC device uses nickel as the pin, is small and thin, and can be directly welded to the original battery, saving space and reducing installation costs.

Protect CLA circuit

The working temperature range of the cigarette lighter power converter (CLA) is very wide, making the charging environment vary greatly. This is because the environment in which the car is located is very harsh and the electrical requirements are very strict. Three main types of faults often occur in CLA:

(1) Excessive current: Will damage the charger or car circuit.

(2) Charger circuit failure: It will blow out the fuse in the charger or damage the car's electrical circuit.

(3) Reverse polarity: The circuit of the mobile phone charger will be damaged.

Installing a current protection device at the input end of the CLA can avoid the above faults. The load current of the terminal equipment and the sensitivity of the power conversion circuit of the CLA itself to faults are the main factors that determine the protection requirements. Generally speaking, at the input side of CLA, overcurrent protection devices are used together with voltage overload protection devices such as transient voltage suppression diodes.

Protecting AC/DC Power Converters

AC/DC power converters have specific requirements for safety and reliability, related to the limitation of short-circuit current and the required temperature protection from overheating of the transformer windings. If the temperature of the winding exceeds the allowable temperature range of the insulating material, the insulation layer will be damaged and broken down, causing an internal short circuit in the transformer or even a fire. Possible causes of excessive winding temperature include excessive ambient temperature, external short circuits, or fluctuations in the input power supply.

The thermal fuse is used for protection in the transformer winding. It is a primary component and does not act appropriately when a transient fault occurs, such as an output short circuit or input voltage fluctuation. The other is to choose CPTC (Ceramic Positive Temperature Coefficient) devices, which have the disadvantage of large low-temperature resistance, which increases power consumption during normal operation. In addition, higher levels of insulation can be used without protective devices, but this will increase the cost.

Protection transformer

There are two common types of damage to transformers: primary overvoltage and secondary short circuit. These two faults will increase the temperature of the transformer coil. If not handled in time, it will cause the insulation of the coil to decrease, the temperature to be out of control, and even the transformer to burn out.

Connecting a thermal fuse in series with the primary side of the transformer and an overcurrent fuse in series with the secondary side is the most commonly used protection solution. Although this method can protect against overtemperature and overcurrent, it requires two components, which increases the cost. Moreover, the fuse is a disposable component and must be replaced after a fault occurs. Experiments have confirmed that when the temperature of the secondary coil of the transformer exceeds 200°C due to a short circuit on the secondary side, the thermal fuse with a rated temperature of 115°C and installed near the center of the core melts. At this time, the insulation of the coil has melted and burned, damaging the transformer. (see picture).

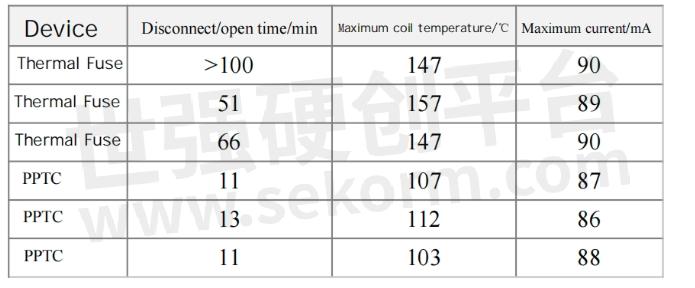

Using PPTC protection devices in transformers is simple and cost-effective. Only one PPTC device with a rated voltage of 240V (AC), installed on the primary side of the transformer, can replace two thermal fuses to achieve over-temperature and over-current protection. When a fault occurs, the over-temperature device in the circuit protection component becomes very important when the coil temperature increases but the current does not increase significantly. Low power power transformers are a good example of this application. Even if a short circuit occurs on the secondary side, the resistance of the PPTC device will increase and the current will be limited to a very low range, which will protect the transformer and avoid destructive faults as shown in the figure. Table 1 shows comparative data for a 120V AC transformer protected by a thermal fuse and a PPTC device.

Table.1

Summary

PPTC devices can effectively protect a wide range of circuits and have been recognized by safety agencies around the world. It not only has reliable performance, but also has self-recovery properties, which reduces the cost of product warranty, service, and repair, and also increases user satisfaction with the product.

- +1 Like

- Add to Favorites

Recommend

- Yint Offered a 1.2GHz Signal Line Protection Solution Including Air Release Tube, PPTC, and ESD devices

- The Operating Principle of Self Recovering Fuse PPTC in USB Protection

- What Protection Devices can be Used to Protect Set-Top Box Protection?

- Yint Developed CBR- series PPTC Thermistors which can Solve the Problem of Abnormal State Protection of Electronic Ballasts

- fuse PPTC for overcurrent protection in photovoltaic street light controllers

- Motor overheating? Wayon PPTC has the solution for you and has High reliability, and meet the AEC-Q200 standard qualified

- The Working Principle and Application Precautions of PPTC?

- A 12V DC Lightning Protection Solution from Yint

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.