The Benefits of Floating Connectors

For space-saving purposes within devices, the design of large-scale electronic circuits combining multiple boards has become mainstream. Contact reliability and workability during assembly are extremely important for Board-to-Board connections. In this article,we introduce the latest trend of Floating Connectors.

Rising Demand for Board-to-Board Connection in Automobiles and Other Applications

Reasons for High Attention to Floating Connectors

In recent years, as electronic devices have become smaller and more multi-functioning, there has been a trend in the industry to divide boards into multiple pieces. In automobiles, for example, with the rapid expansion of ADAS (Advanced Driver-Assistance Systems)and electrification, the proportion of electronic boards occupied by on-board components is on the rise, and at the same time, there is a growing need to divide and stack boards in order to reduce the size of the chassis, given the limited space available in the car. It also implements some functions on the daughterboard to extend lineups with a common motherboard and incorporates platform designs that make it easier to change designs.

Connectors that are responsible for transmitting signals between boards become crucial in the multiple board design. Firstly, boards are loaded with tall components such as high-capacity capacitors or heat sinks and heat pipes for cooling high-heat components

such as high-performance processors. Adequate distance between boards is required to prevent damage from rising temperatures and physical interference between components. In addition, automobiles and industrial machinery are used in more severe environments such as vibration and temperature, than OA equipment and home appliances.

In the case of rigid connectors that do not have a movable structure, where stress is easily concentrated in the connector or a solder joint with the board, there is also a concern that a crack may occur in the connector itself, or at the solder joint with the board.

Taking these conditions into consideration, connecting via cables or flexible boards, for example, can be an option, but it can also be a factor to increase the number of parts and assembly man-hours.

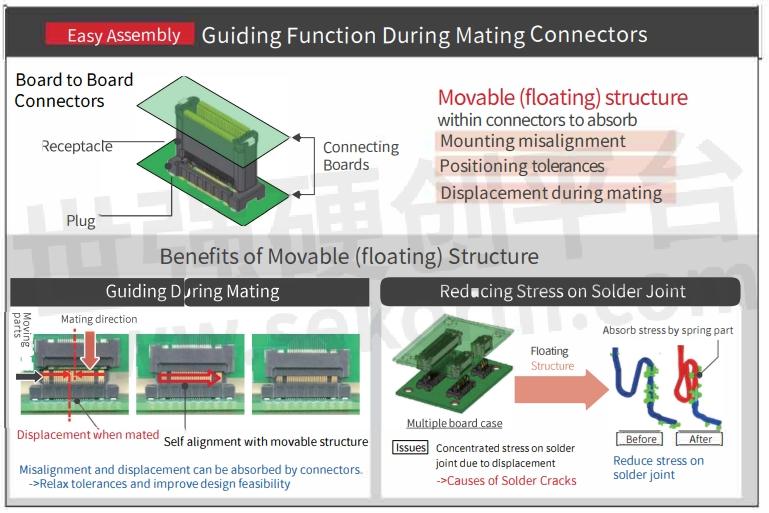

Under such circumstances, a floating connector in which the mating area is movable can be useful. The floating connector partially separates the molded part and connects them with a metal conductor with spring properties to ensure electrical continuity and connection reliability in the movable part during mating. The system absorbs mounting misalignment, positioning tolerance, and displacement during mounting within the movable range. Rigid connectors without movable structure may result in unsuccessful mating due to a slight misalignment or breakage caused by forced engagement. Floating connectors, on the other hand, can drastically reduce such troubles.

The main feature of a floating connector. Even if there is a slippage in the mounting or installation, the spring part in the connector will absorb the stress as long as it is within the movable range, which improves workability and reduces breakage.

Front Line of Floating Connectors-1mm Floating and High-Speed Transmission

KYOCERA is developing unique products among several manufacturers of floating connectors. Line up includes 0.4 mm,0.5mm, and 0.635mm pitch connectors under the brand name FloXY.

One of the featured products is the 5656 series,0.5mm pitch and floats 1.0mm, providing two times the connector pitch in movement range. It incorporates dual point contacts to enhance contact reliability. Another product in the same category is the 5655 series with a low er profile and 0.5mm floating range. Its stacking height ranges from 4mm, the lowest height in the industry.

Another featured product is the 5652 series which supports 16Gbps high-speed transmission while ensuring a wide floating range of 0.85mm. A floating connector has a structurally movable spring part that is exposed to air, This structure causes impedance mismatching, resulting in inter France of high-frequency signals, namely high-speed transmission.

This is the fateful phenomenon of floating connectors, so to speak, but Kyocera has made a major reconsideration of the design of terminals that become conductors. By optimizing the impedance through simulation and prototype verification, a floating connector capable of supporting PCle Gen 4 and USB 3.1 Gen 2 has been realized ahead of other companies.

Advanced Analysis Technology to Realize Highly Reliable Products for Automotive Industry

According to Kyocera, FloXY products meet all automotive requirements such as heat resistance. In the design and development of floating connectors, various technologies were introduced, including the use of high-frequency analysis, which also helped to optimize the impedance of the 5652 series, as well as structural analysis of the entire connector, thermal analysis when energized which takes into account the temperature rise, and resin flow analysisduringinjection molding.

Outline of the lineup of Kyocera's "FloXY"0.5 mm pitch products. The 5652 series which is capable of high-speed transmission is used for inside the car cabin such as infotainment, while the 5656 and 5655 series are in and outside of the car cabin, respectively. A low profile version of the high-speed transmission type is also in the development plan.

- +1 Like

- Add to Favorites

Recommend

- Kyocera Named to “Top 100“ Global Innovators List for Third Consecutive Year, Marking Eighth Appearance

- Kyocera and Digital Grid Begin Joint Demonstration of Renewable Peer-to-Peer Power

- KYOCERA Named Among “Top 100“ Global Innovators for 7th Year by Clarivate

- Kyocera Corporation and SoftBank Corp. Succeeded in Demonstration of Backhaul System Utilizing 5G Millimeter-Wave

- Kyocera Introduces Cutting-Edge Peltier Module with 21% Increase in Cooling Performance

- KYOCERA Lanuched Ultra-Small Crystal Units CX1008SB Series Achieving the Same Performance as Kyocera‘s Previous With A 33% Reduction in Size

- Kyocera Awarded Sekorm the Excellent Distributor Award for the Remarkable Development of Automotive Electronics Market

- Kyocera Participates in TactoTek Funding with €5 Million Investment and Strategic Partnership

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.