Kyocera Introduces Cutting-Edge Peltier Module with 21% Increase in Cooling Performance

KYOCERA Corporation (President: Hideo Tanimoto, hereinafter: Kyocera) today introduced a new Peltier (thermoelectric) module with improved heat absorption. This new Peltier Module has a maximum heat absorption rate*1 21% higher than Kyocera's conventional products, enabling dramatically enhanced cooling performance. Kyocera's Peltier modules are primarily used for temperature control of automotive batteries and seats, and this improvement in cooling performance will contribute to battery longevity. As of June 2024, we have shipped a total of 32 million units for automotive applications, and we will continue to supply components that support the growth of the automotive industry.

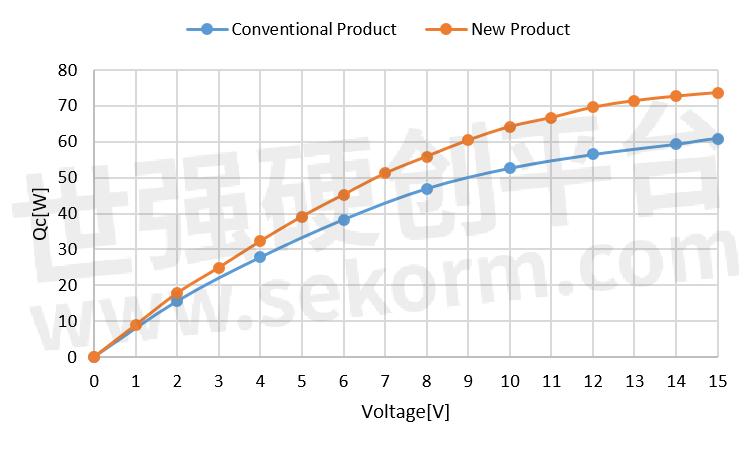

*1 Maximum Heat Absorption (Qcmax) refers to the amount of heat absorbed by the Peltier module when operated at maximum current. It is defined as the temperature difference between both ends of the thermoelectric semiconductor being 0°C.

Kyocera's Peltier Module

(Width 40mm × Depth 40mm × Height 2.17mm)

About Peltier Modules

A Peltier module is an energy conversion device with semiconductor elements sandwiched between copper substrates. When electricity passes through, one side of the substrate absorbs heat (cooling), while the other side releases heat (heating). This allows for rapid changes in surface temperature between heating and cooling, as well as the ability to adjust or maintain a specific temperature.

Features of Kyocera's Peltier Module

1.High Heat Absorption

Kyocera's Peltier modules stand out due to their unique element technology (single crystal growth technology), which enables high heat absorption. Advances in this technology enable the maximum heat absorption capacity*1 to rise 21% compared to Kyocera's conventional products. Our new Peltier module can absorb heat more efficiently, thereby enhancing cooling performance.

Graph: Comparison of Heat Absorption between Conventional and New Products

2.High Responsiveness

Faster heating and cooling, in combination with a copper plate that provides high thermal conductivity, allow more rapid temperature-control response.

3.High Reliability

At Kyocera, we prioritize the reliability of our Peltier modules. We coat the element sides with resin to protect them from corrosion due to condensation. Moreover, the entire process, from development to manufacturing and shipping, is handled at our own Japan-based facilities, guaranteeing the highest quality control standards and instilling confidence in our customers.

4.Customizable

Our Peltier module is highly customizable with temperature-sensing thermistors and/or heat dissipation fins. We can also accommodate size adjustments to match the customer's application and casing requirements, providing a versatile solution for a wide range of automotive and other temperature control needs.

- +1 Like

- Add to Favorites

Recommend

- Semiconductor Peltier In Medical Application

- RX23E-A 32-bit MCU Realizes A Thermoelectric Peltier Controller Achieving A Control Resolution of about 5m°C

- SA356 High Power Transmission Module—A 48K Sampling Audio Transmission Module Featuring 3KM Transmission Distance and Low Latency

- RF-STAR Launched The CC2640R2L Module With A Lower Cost And High Performance

- RF-STAR RF-AL42UH Module Based on Lora Technology is Particularly Suitable for Waste Classification Solutions

- 6 Main Fields of Application for WIMA PowerBlock Module

- Neoway Introduced a New Wi-Fi HaLow Module, Which Will Fill the Perennial Vacancy of LPWA IoT Technology

- Kyocera Awarded Sekorm the Excellent Distributor Award for the Remarkable Development of Automotive Electronics Market

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.