Shenzhen Car Charging Chip Factory: Notes on IC Unpacking and IC Storage Methods

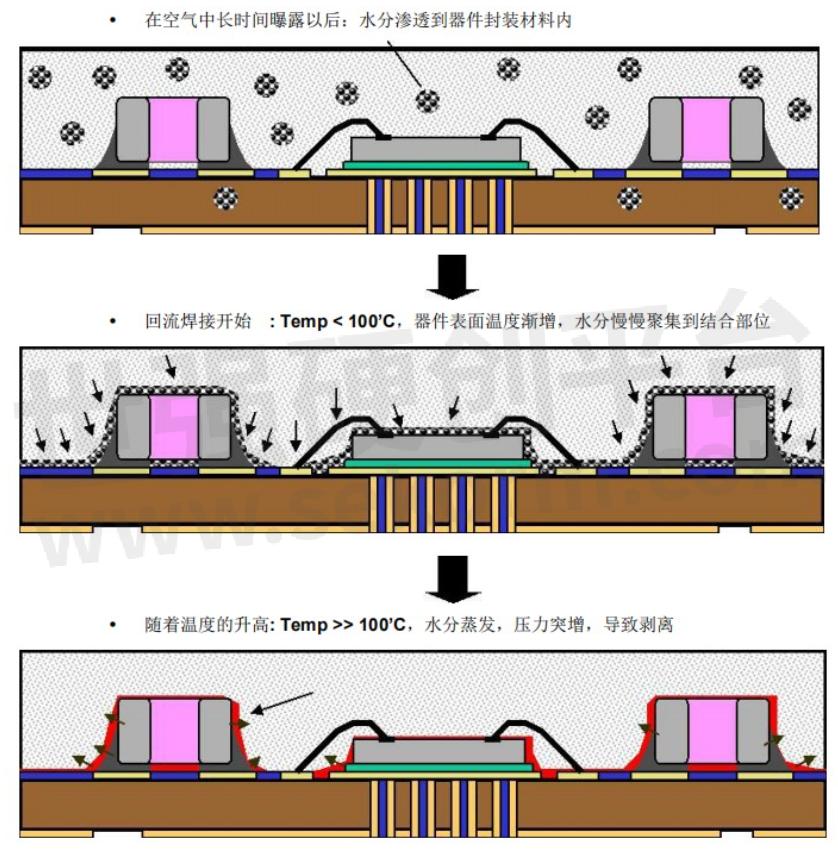

There are still hundreds of IC chips left to be pasted, but if they are taken out and used again, there will be abnormalities. What is the reason for this? The simple answer is that your IC chip has not been properly stored, and if the IC enters the air and becomes damp, the following abnormal phenomena will occur.

Fig.1

Today, Shenzhen Car Charging Chip Factory will introduce to everyone the precautions and storage methods for IC unpacking:

Storage life of IC vacuum-sealed packaging:

1. Please note the sealing date of each vacuum packaging box;

2. Shelf life: 12 months, storage environment conditions: at a temperature of<40 ℃ and humidity of<90% R.H; 3. Inventory control: Based on the principle of "first in, first out".

Time limit for SMT assembly after IC packaging is opened:

1. Check the humidity card: the displayed value should be less than 20% (blue);

If>30% (red), it indicates that the IC has absorbed moisture.

2. SMT workshop environment temperature and humidity control: operate at a temperature of 22℃ (± 4℃) and a humidity of 60% R.H (± 20%);

2.2. Non heat-resistant packaging material, 40℃ (± 3℃), 192 hours;

3. After baking, immediately use it for SMT production, or add an appropriate amount of desiccant and seal the packaging, and store it in a drying cabinet.

If the unpacked IC components are not used up within 48 hours:

1. IC components must be re-baked to remove moisture absorption issues;

2. Baking temperature conditions:

2.1. High-temperature resistant packaging material, 125℃ (± 5℃), 24 hours;

Temperature, time, usage requirements, humidity sensitivity level, etc. for IC baking

Firstly, the requirements of "Incoming Packaging Instructions" shall prevail;

(If there is no explanation for the incoming packaging, this article shall prevail)

Moisture level classification of outer packaging stickers and SMT service life after opening:

1. After unpacking, IC must complete the SMT welding procedure within 48 hours;

2. The number of ICs received per shift cannot exceed the production usage of that shift;

3. Unpacked ICs, tube-mounted ICs, etc. must be stored in a drying cabinet with a humidity of<20% R.H.

Try to use it within 48 hours after unpacking, and there is no need for additional storage work. However, it is necessary to ensure that the environmental conditions are below: temperature → 25℃ ± 5℃ humidity → 60% RH;

When the remaining IC is not used for a long time after being unsealed, it should be stored in an industrial moisture-proof cabinet or an effective desiccant should be placed in an anti-static aluminum foil bag and vacuum sealed. The desiccant will become ineffective after moisture absorption, and its storage time should not be too long. The remaining chips need to be used up within 7 days;

During a period exceeding 7 days, the following baking treatments must be performed before use (please limit to one use); If the indoor environment is very dry and the non-destructive quality is verified, it can be relaxed to 14 days; If placed in an industrial moisture-proof box below 5% RH, it can be stored for a long time.

Regarding the IC baking method:

1) In the case of tape installation: temperature → 60-65℃, humidity → 9-10% HR (under this condition, the best method is to add ultra-low humidity below 5% RH);

2) In the individual state of the product (in bulk or on a PCB), temperature → 100-110℃, humidity → 10% HR;

6、 Warehouse storage:

1) Storage conditions: temperature → 25℃± 5℃; Humidity → below 60% RH; The chips stored in the warehouse, due to packaging material factors and considering the absorption of moisture, are recommended to undergo moisture-proof treatment (stored in an industrial moisture-proof cabinet, or baked together with desiccant and placed in an anti-static aluminum foil bag for vacuum storage);

2) It is recommended to use the IC chips stored within one year; After opening the packaging, the storage environment of the chip should be kept below 28℃ and 60% RH; The welding/use of these materials should be completed within 48 hours; If the chips are unused or unused, to facilitate storage, it is recommended to return them to anti-static aluminum foil bags and reseal them for storage; When used again, baking is required under the same conditions as the baking after opening.

Furthermore, it is recommended that users can reasonably unpack a relatively large number of materials according to production needs. Even if there are unused chips, they can use an industrial moisture-proof cabinet for storage. To meet the storage conditions of industrial moisture-proof boxes that can maintain long-term stability below 5% RH, and to record the information of chips stored in the moisture-proof cabinet, there is no need to overly consider how many days they will be used up and how many days they will need to be baked.

Warehouse chip storage recommendations:

Environmental requirements:

Chips must be stored in a clean, ventilated, and corrosion-free warehouse; Partition and off-ground storage; Unless otherwise specified,

The temperature and relative humidity of the warehouse must meet the following requirements:

A: Temperature: -5~30 ℃

B: Relative humidity: 20%~75%

The quality of the warehouse storage environment directly affects the length of the limited storage period.

Special requirements:

1. For electrostatic sensitive devices, they should be stored in containers with an electrostatic shielding effect.

2. Electronic components that are sensitive to magnetic fields but do not have magnetic shielding themselves should be stored in containers with magnetic shielding effects.

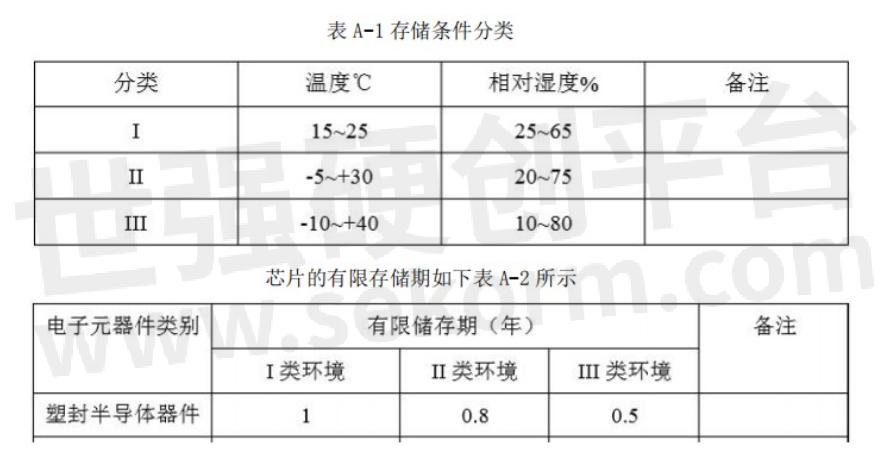

3. The limited storage period of chips is related to the environmental conditions of storage and the environmental conditions of warehouse storage can be divided into the following three categories:

Table.1

- +1 Like

- Add to Favorites

Recommend

- QC3.0 High Integrated Multi Protocol Car Charging Chip CX8830 Only Requires 11 Peripherals to Achieve Fast Charging Function

- Power Up Your Car with an AC-DC Converter: A Game-Changer for On-the-Go Charging

- How PD Fast Charging Technology Will Revolutionize Your Mobile Device Charging Experience

- JoulWatt JW3119E Power Supply Protocol Chip Passes UFCS Certification, Enabling the Development of Integrated Fast Charging

- Hottech‘s “Linear Lithium-ion Battery Charging Management Chip“ Won The National Invention Patent Certificate

- PD Fast Charging Technology: A New Charging Standard for Modern Life

- Fast Charging Adapter: Technology Empowers, Accelerates Charging Experience

- JoulWatt Attended the 2024 Asia Fast Charging Conference and Shared New Products in the Field of Buck-Boost Charging Controller

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.