Digital Isolators: Invisible Guardians of System Security and Personal Safety

If there is anything requiring 100% attention in circuit design, they must include isolators.

Isolators themselves do not have special computing, processing, or conversion capabilities, but their evolution is inextricably linked to the development of industry, automotive, medical, and home electronics, etc. Because their high reliability and performance soundly underpin system security, you should not brush aside isolators in your circuit design.

Isolators as invisible guardians

Some may see isolation as a too-often-heard topic, but it plays an important role in protecting circuit and personal safety.

In simple terms, the voltage of the execution system and the control system in electronic devices varies greatly – hundreds VAC vs. low VDC. In life, we isolate low-voltage and high-voltage systems, which also applies to circuit design. High-voltage systems often are more prone to electrostatic discharge, radio frequency, switching pulse, and power disturbance, which can cause a voltage surge that is a thousand times higher than the voltage limit of many electronic components. Most importantly, these voltage surges are more likely to cause harm to the human body, in addition to the noise and damage to electronic circuits.

Here’s a simple example. The battery voltage in an electric vehicle (EV) can reach 400V or even 800V, but the driver can calmly and safely operate all devices, instruments, and knobs inside it. Behind this calmness and safety, various forms of isolation play a crucial role – they build a safe and reliable connection between high and low-voltage systems.

Considering such a profound effect, the selection of isolation type particularly matters.

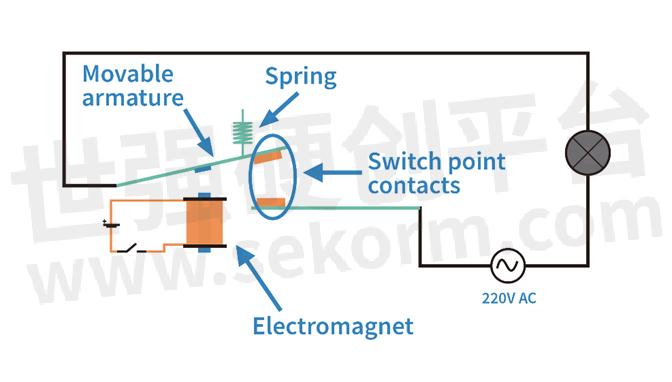

Since day one of electricity use by humans, people have longed for safe and reliable means of power control. In the 1830s, Joseph Henry, an American physicist, invented the electromagnetic relay using the theory of electromagnetic induction when he studied circuit control. Inspired by the phenomenon of magnetic force generation and disappearance in power-on and power-off conditions, he used an electromagnet to control the opening and closing of another circuit with high voltage and high current, enabling remote control and protection of the circuit.

By controlling the electromagnet using a dry cell, a 220V AC electric circuit can be driven to enable safe control (or information transmission), which has a ring of “moving a thousand pounds with four ounces”. This simple procedure is the underlying principle of isolation, i.e. two unrelated circuits that are insulated from each other are connected in a certain way.

However, the electromagnetic relay has obvious disadvantages, such as a large footprint, high power consumption, and easy vulnerability.

To overcome the aforementioned shortcomings, an optocoupler came into being. It uses photovoltaic conversion to enable transmission and control and implements a similar function at the IC level. Opto-isolator, based on photoresistor, was launched in 1968. Compared with transformers, optocouplers featured a small footprint, lightweight, low cost, and high reliability, which quickly became the mainstream in the market. The era of optocoupler development also saw the evolution of integrated circuits (ICs) and information technology. With increasing interaction between low-voltage control and computing units and high-power motors and power supplies, optocouplers have been greatly improved.

Undoubtedly, performance, power consumption, and footprint are never-evade topics in the microelectronics world, and any strong technology cannot steer away from them. Optocouplers now meet the same challenges with electromagnetic relays – constrained by laser and photosensitive diodes, optocouplers lose their edge in terms of footprint, power consumption, and reliability.

Thanks to the advances in semiconductor technology, Digital isolators have become rising stars.

Merits and demerits of digital isolators

It’s not difficult to understand digital isolators. They are similar to optocouplers, except that the photovoltaic conversion and modulation is changed to other technologies. However, it’s noted that optical attenuation will not occur in digital isolators. Unlike optocouplers, digital isolators provide many benefits, including good switching characteristics, low vulnerability to aging, high reliability, high voltage withstand ability, high speed, and energy transferability. All these are underpinned by semiconductor technology.

By underlying principles, digital isolators can be divided into capacitive isolators and magnetic ones.

Capacitive isolator, as its name suggests, uses the micro-capacitors inside the IC for high voltage isolation on the left and right sides, and adopts highly dielectric materials in the middle for voltage isolation. The capacitor is a device that can store charge and comprises two conductor plates and a medium. It allows high frequency to pass through but blocks low frequency. The intermediate medium can isolate low-frequency or DC high voltage signals.

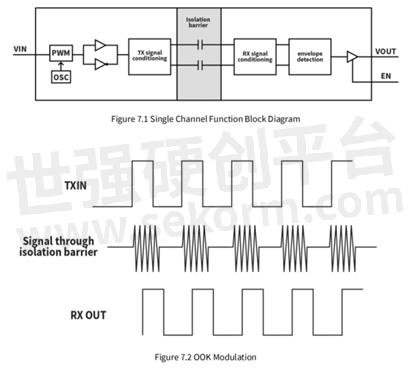

Using a capacitor’s characteristic of allowing high frequency to pass through but blocking low frequency, modulation and transmission of signals can be performed. When a high-flow digital signal is input, the signal will be modulated inside the IC – the high-frequency signal will be modulated into a low-frequency signal, allowing it to be transmitted to the other side of the IC. Typical OOK (On-Off Key) modulation is as follows: “0, 1” signals will be modulated using different frequencies. For example, 1 represents a high-frequency signal, 0 represents an unmodulated DC signal, and then two state-switching signals are transmitted.

Block diagram of capacitive isolator product and schematic diagram of OOK modulation

Magnetic isolators are similar to capacitive ones, except that the former uses coils and electromagnetic conversion to implement data transmission.

In a nutshell, digital isolators further address the disadvantages of optocouplers in terms of reliability, transmission rate, robustness, footprint, and service life.

Perfection never exists in the realm of technology. Digital isolators boast visible advantages, but there are always trade-offs.

First, digital isolators are relatively new, so their reliability is continuously being improved and demonstrated. With the successive introduction of related international and domestic standards, a complete range of approval processes and standards have been established, and customers from various industries have gradually given their recognition.

Second, optocouplers still account for a dominant share in the industry, especially in some conventional applications. Therefore, the shift from optocoupler to digital isolator cannot be done overnight, because the pins and input type of digital isolators are not fully compatible. This requires changes in design. Sometimes customers are not willing to switch to digital isolators because of risk considerations. To this end, there is a Pin-to-pin replacement alternative in the industry. In this solution, the optocoupler can be directly replaced and pins are compatible, and the built-in circuit is implemented in the input characteristics to simulate the diode characteristics. In this way, a digital isolator can function exactly the same as an optocoupler device in the same application settings, and direct design replacement can be achieved.

At last, common mode interference may occur in capacitive isolators, which needs to be suppressed.

A typical OOK technology is simple and clear, i.e. the input signal is directly and correspondingly modulated and then demodulated on the other side. After high-frequency modulation, the signal and high-frequency common mode circuit are transmitted through the same path, so there will be common mode interference. This is also a shortcoming of ordinary capacitive isolators.

Considering the above-mentioned problems, particular attention should be paid to the selection of devices. There are several methods to significantly enhance the immunity to common-mode interference. Taking the Chinese isolator manufacturer NOVOSENSE as an example, it has developed the Adaptive OOK® proprietary modulation technology based on OOK, which improves the capability of digital isolators to resist common-mode interference.

The so-called Adaptive OOK® technology uses the common mode detection circuit inside the IC to detect the state of common mode signals, and then depending on the signals detected, dynamically and adaptively modulates the internal key circuit characteristics or gains. When the common mode noise is large, it can better suppress the noise, to provide higher robustness and enhanced immunity to common mode interference.

Another benefit of adaptive modulation is that high common-mode interference resistance does not need to be guaranteed at full operation state. Only when the instantaneous interference is relatively high, does the circuit need to perform more functions to suppress interference. In most cases where there are no harsh conditions and a low requirement for common-mode interference resistance, Adaptive OOK® technology can strike a good balance between system properties and power consumption to optimize the overall performance.

Bring isolators further

In the digital isolator market segment, only a few companies provide magnetic isolators, and capacitive isolators are the preferred choice of manufacturers. What’s more, the number of capacitive isolators sold is growing very fast. In addition to patent-related reasons, the overall manufacturing process of capacitive isolators is relatively simple and does not differ greatly from general non-isolated devices in terms of wafer production. This allows capacitive isolators to deliver a big cost advantage.

Furthermore, the process capability and performance of capacitive isolators are constantly improved. Particularly, their voltage withstands and surge resistance capabilities have been comparable to magnetic isolators, allowing capacitive isolators to meet the requirements of a wide range of applications.

The products from NOVOSENSE can prove the above-mentioned trend. For example, the first-generation NSI81xx series meets the basic isolation requirements. The second-generation NSI82xx series answers the requirements of enhanced isolation and provides enhanced resistance to common-mode interference, EMC performance, and other electrical properties. According to NOVOSENSE, its third-generation products will further improve the voltage withstand capability and robustness.

Figure: Different isolation ratings

When it comes to the design of a capacitive isolator, the theory is simple, but the optimization and innovation of some processes and microarchitectures will have highly great effects on the overall performance. A case in point, from OOK to Adaptive OOK®, NOVOSENSE has done a lot to realize this “one-step-further” effort.

Performance. Process capability and microarchitecture optimization contribute to the continuous improvement of voltage withstand capability. For example, assuming that highly dielectric SiO2 is filled, different elements are also needed to further improve the voltage withstand capability. In addition, the electric field strength distribution of the capacitor can greatly affect the voltage withstand capability of the isolator. Therefore, the design of the capacitor structure, shape, and other micro-architectures of each manufacturer, will affect the performance.

Robustness. Isolator products are more widely used in industry, automotive, and other high-voltage applications. Isolators are required to meet safety specifications. In applications involving safety, the selection of isolators having safety approvals is mandatory.

To match specific requirements of analog, interfaces, and signal chains, manufacturers need to introduce different product families for more applications. Isolator makes no exception. By combining the basic isolation function with other interfaces, drives, or sampling knowledge, isolator technology can have wider applications.

Backward derivation of product definition from applications is the main idea of product development, and also the greatest challenge. The definition of an “isolation+” product around applications is not the same as that of pure digital isolators.

Take an isolated driver for example, in addition to the digital signal processing capability, manufacturers are required to be familiar with the power knowledge related to the driver in specific applications and ensure compatibility with power tubes from different manufacturers. Furthermore, SiC and other third-generation wide band gap semiconductor applications pose more security and data transmission requirements for isolated drivers.

For isolated interface products, the ESD and anti-interference capabilities need to be considered. Isolated sampling also requires good expertise in high-precision signal chains.

In addition, isolators sometimes need to be used together with a power supply. In this setting, isolators that integrate the isolated power supply were launched.

According to our knowledge, NOVOSENSE and other Chinese and global manufacturers coincidentally plan more isolation product categories – shifting from a single category to an “isolation+” expansion strategy, to provide isolation capability for more products.

An increasing number of new applications and new markets push digital isolators to the same starting line as optocouplers. More and more niche applications, including EV, photovoltaics, and energy storage, are emerging, and the demand for digital isolators is rocketing. Customers are more willing to select digital isolators in the design of these new applications.

Closing remarks

We have witnessed the glory of electromagnetic relays and optocouplers, and now the era of digital isolators has come. Check your circuit board carefully. If other parts already adopt the latest technology, but an optical coupled isolator is still used, this is not the best choice. Discover more about digital isolator technology.

- +1 Like

- Add to Favorites

Recommend

- NOVOSENSE Has Launched Multiple Automobile-qualified Chips with Breakthrough Innovation Technology In the first half of 2022!

- NOVOSENSE Assists the Formulation of LIN Transceiver Chip Standard, Promoting the High-quality Development of the Automotive Chip Industry

- NOVOSENSE Won VDE Premium Quality Award for High Quality Development

- NOVOSENSE Released a New 1200V Series SiC Diode with Typical Fowrard Voltage of 1.39V, Contributing to the SiC Ecosystem

- NOVOSENSE NST1002 Temperature Sensor Facilitates Accurate CGM Measurement with Glucose Monitoring Black Technology

- NOVOSENSE‘s New Isolation Voltage Sampling Chips NSI1312x Series Support +1.2V Bidirectional Linear Input Voltage

- Novosense Selects Tower Semiconductor for Volume Manufacturing of their Magnetic Sensor for the Automotive On-board Charger Market

- NOVOSENSE Automotive-qualified CAN Interface Chip Boosts Smart Control of Vehicle

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.