NOVOSENSE Released a New 1200V Series SiC Diode with Typical Fowrard Voltage of 1.39V, Contributing to the SiC Ecosystem

Silicon carbide (SiC) is a third-generation wide bandgap semiconductor material with superior properties compared to silicon (Si). SiC boasts higher dielectric breakdown strength, faster saturation electron drift speed, and better thermal conductivity. These attributes enable SiC to excel in high breakdown voltage, high-speed switching, low forward voltage, and high efficiency for power semiconductor devices, thereby reducing energy consumption and system size. SiC’s advantages are particularly beneficial in high-voltage and high-power applications such as photovoltaic, energy storage, charging, and electric vehicles.

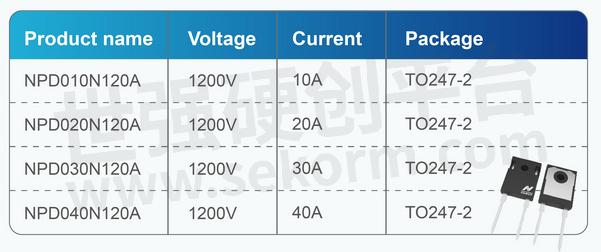

NOVOSENSE has launched a new 1200V SiC diode series, designed for applications such as photovoltaics, energy storage, and charging. The diodes offer exceptional efficiency in single- or three-phase PFC, isolated or non-isolated DC-DC circuits, meeting the needs of medium- and high-voltage systems.

SiC Diodes: Superior Performance Over Silicon-Based Counterparts

1. Zero Reverse Recovery Current

As shown in the figure below, the SiC diode exhibits a near-zero reverse recovery current, significantly outperforming its silicon-based counterpart. Furthermore, the magnitude of this current remains unaffected by factors such as foward current, turn-off speed (di/dt), and junction temperature.

2. Enhanced Switching Frequency

SiC diodes, with their exceptional reverse recovery characteristics, can be paired with high-frequency switching devices to increase switching frequency, ultimately reducing system size and cost.

3. Reduced Forward Voltage

SiC diodes, featuring a Schottky structure, exhibit lower forward voltage compared to 1200V silicon-based diodes.

4. Improved EMI Performance

The minimal reverse recovery current of SiC diodes results in superior EMI performance.

5. Superior Thermal Conductivity

SiC materials show better thermal conductivity, helping to lower junction temperature and improve system reliability.

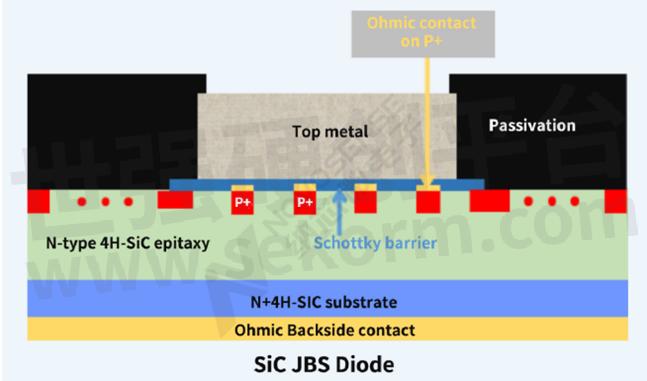

As illustrated in the figure below, NOVOSENSE SiC diodes employ an MPS (Merged PiN Schottcky) structure, offering significant advantages over traditional JBS (Junction Barrier Schottcky) structure. The PN structure in the MPS structure allows for low forward voltage at high surge current situation achieved by injecting a large number of minority carriers into the high-resistance drift region, thus significantly reducing resistance in the drift region. The device’s surge current capability is dramatically enhanced while maintaining a constant forward voltage at normal operating condition.

Schematic diagram of NOVOSENSE SiC diode structure

The typical fowrard voltage of the NOVOSENSE NPD020N120A SiC diode, measured at its rated current, is 1.39V. The typical non-repetitive surge current can reach 220A (tested in lab), which is 11 times of the rated forward current, outperforming industry standards.

This implies that NOVOSENSE SiC diodes exhibit reduced forward voltage and enhanced surge current capability during transient high current shocks. This performance advantage enables NOVOSENSE SiC diodes to excel in high-power applications, ensuring system reliability and stability.

NOVOSENSE maintains a rigorous quality management system to deliver the most reliable SiC diodes to customers. We enforce strict quality control measures throughout the SiC chip production process. Each SiC diode undergoes 100% static electrical parameters testing and 100% avalanche breakdown testing. To ensure product reliability, we verify our products according to JEDEC standards and even apply more stringent test conditions. For example, in the HTRB project, we increase the voltage tolerance to 100% of the rated voltage (using 1200V for HTRB reliability tests on 1200V series diodes). In addition, we extend the test duration from 1000 hours to 3000 hours, among other measures, to guarantee product reliability.

NOVOSENSE is committed to ensuring product quality and reliability through stringent control measures and rigorous testing processes, providing customers with the most dependable SiC diodes.

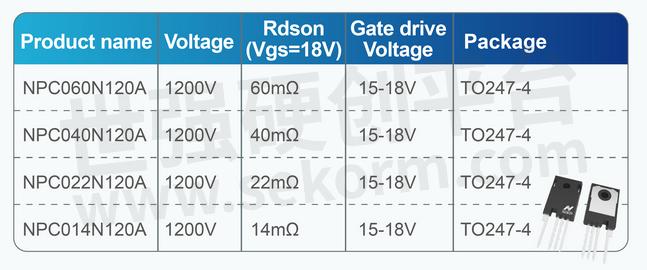

Upcoming 1200V SiC MOSFET Launch

In addition to SiC diodes, NOVOSENSE is actively developing and validating 1200V SiC MOSFET products, set to launch soon. These SiC MOSFET products will undergo extensive auto-grade qualification test to ensure full compatibility with automotive applications.

- +1 Like

- Add to Favorites

Recommend

- NOVOSENSE Has Launched Multiple Automobile-qualified Chips with Breakthrough Innovation Technology In the first half of 2022!

- NOVOSENSE Assists the Formulation of LIN Transceiver Chip Standard, Promoting the High-quality Development of the Automotive Chip Industry

- NOVOSENSE Won VDE Premium Quality Award for High Quality Development

- NOVOSENSE NST1002 Temperature Sensor Facilitates Accurate CGM Measurement with Glucose Monitoring Black Technology

- NOVOSENSE‘s New Isolation Voltage Sampling Chips NSI1312x Series Support +1.2V Bidirectional Linear Input Voltage

- Novosense Selects Tower Semiconductor for Volume Manufacturing of their Magnetic Sensor for the Automotive On-board Charger Market

- NOVOSENSE Automotive-qualified CAN Interface Chip Boosts Smart Control of Vehicle

- NOVOSENSE Provides A One-stop Solution for Power Drive and Signal Sampling in Electronic Control Systems

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.