What Are the Common Types of FPC Flexible Circuit Boards?

According to BLF, at present, FPC flexible circuit boards are single-sided, double-sided, Multi-layer flexible circuit boards, and rigid-flexible combined circuit boards of four kinds.

Single-side flexible circuit board is the lowest cost when the electrical performance requirements are not high printed board. In single-side wiring, a single-side flexible circuit board should be selected. It has a chemically etched conductive pattern layer, and the conductive pattern layer on the flexible insulating substrate is calendered copper foil. The insulating substrate may be polyimide, polyethylene terephthalate, arylamide fiber ester, and polyvinyl chloride.

A Double-sided flexible circuit board is a conductive graph etched on both sides of the insulating substrate film. The metallization hole connects the two sides of the insulating material to form a conductive path to meet the flexural design and use function. The covering film can protect the single and double-sided wire and indicate the position of the element.

The multi-layer flexible circuit board is a single or double-sided FPC flexible circuit board of 3 or more layers laminated together, through drilling and electroplating to form a metalized hole, forming a conductive path between different layers. In this way, there is no need to use a complex welding process. Multilayer circuits have great functional differences in terms of higher reliability, better thermal conductivity, and more convenient assembly performance. The interaction of assembly size, number of layers, and flexibility should be taken into account when designing the layout.

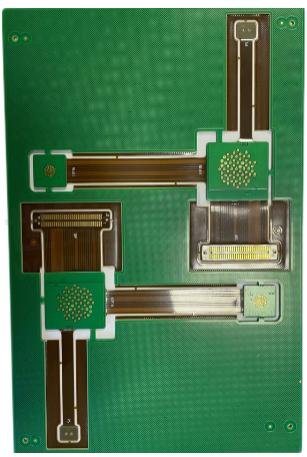

The traditional rigid-flexible circuit board is composed of rigid and flexible substrates pressed together. The structure is tight and metalized to form a conductive connection. If a printed board has both front and back components, the rigid flexible circuit board is a good choice. But if all the components are on one side, it is more economical to use a double-sided flexible circuit board and layer FR4 reinforcement on the back.

FPC flexible circuit board with mixed structure is a kind of multi-layer board, the conductive layer is composed of different metals. An 8-layer board uses FR-4 as the medium for the inner layer and polyimide as the medium for the outer layer, with leads extending from three different directions of the motherboard, each of which is made of a different metal. Copper alloy, copper, and gold are used as independent leads. This kind of hybrid structure is the only feasible solution when the relationship between electric signal conversion heat conversion and electrical properties is harsh. It can be evaluated by the convenience of the interconnecting design and the total cost to achieve the best performance-price ratio.

- +1 Like

- Add to Favorites

Recommend

- Detailed Classification of FPC Connectors

- What is the HDI (High-Density Interconnect) Printed Circuit Boards?

- Price and Cost of Circuit Boards

- Maswell 5G Miniaturized flexible FPC Internal Antenna series with High Gain and Shape reconfigurable

- Maxwell‘s FM radio planar antenna using FPC flexible medium supports customization, and the frequency covers 87-110MHz

- Powerful AC to DC Rectification on Printed Circuit Boards

- The Difference between FFC Connectors and FPC Connectors

- FFC FPC Connector: The Key to Seamless Electrical Connections

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.