Detailed Classification of FPC Connectors

With the rapid development of electronic technology, the application of Flexible Printed Circuit (FPC) boards in various electronic devices is becoming increasingly widespread. FPC Connectors, serving as bridges between FPCs and other circuit boards, come in a wide variety, each with its characteristics. This article will provide a detailed overview of the classification of FPC connectors to help readers better understand and utilize these connectors.

I. Classification by Connection Method

1. Pressure-type FPC Connectors

Pressure-type FPC connectors mainly fix the FPC and the connector together through pressure. This connection method features a simple structure and convenient operation, suitable for scenarios requiring rapid assembly and disassembly. However, the connection strength of pressure-type connectors is relatively low and may not be suitable for high vibration or impact environments.

2. Soldering-type FPC Connectors

Soldering-type FPC connectors fix the FPC and the connector together through soldering, offering higher connection strength and stability. This connection method is suitable for scenarios demanding high connection reliability, such as automotive and aerospace fields. However, the soldering process requires certain professional skills and the connection is not easily disassembled or repaired.

Slot-type FPC connectors utilize a slot structure to achieve connection between the FPC and the connector. This connection method features easy installation and simple disassembly, suitable for scenarios requiring frequent replacement of FPCs. Slot-type connectors usually exhibit good electrical performance but may be affected by slot wear, requiring regular inspection and replacement.

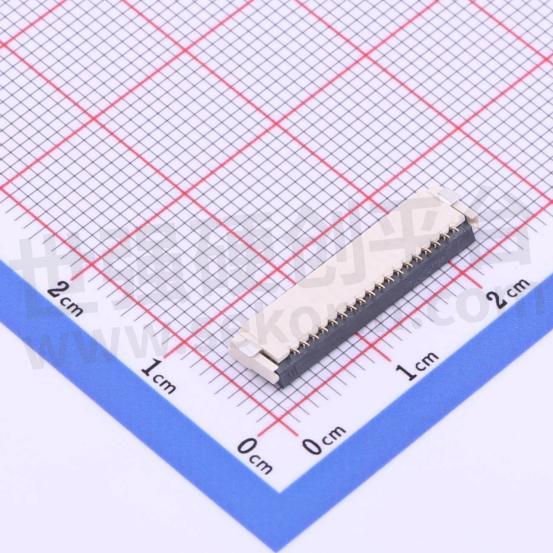

FPC Connector KH-FPC1.0-H2.0SMT-18P-QCHF

Ⅱ. Classification by Structural Type

Right-angle FPC connectors feature a structure with a right-angle bend, facilitating the connection between FPC and other circuit boards within limited space. This type of connector is suitable for compact electronic devices such as smartphones, tablets, etc.

Folded FPC connectors can be bent as needed to accommodate different installation angles and spatial requirements. These connectors offer high flexibility and are suitable for various complex installation environments.

Stacked FPC connectors allow multiple FPC layers to be stacked together, achieving high-density connections. This type of connector is suitable for electronic devices requiring high integration, such as servers, data centers, etc.

Ⅲ. Classification by Application Field

1. Consumer Electronics FPC Connector

Consumer electronics FPC connectors are widely used in consumer electronic products such as smartphones, tablets, televisions, etc. These connectors typically feature small size, light weight, and stable performance to meet the aesthetic and performance requirements of consumer electronic products.

2. Industrial Automation FPC Connector:

Industrial automation FPC connectors are suitable for industrial automation equipment, robots, and other industrial applications. These connectors typically offer high vibration and shock resistance to ensure stable operation in harsh industrial environments.

3. Automotive Electronics FPC Connector:

Automotive electronics FPC connectors are primarily used for connecting various electronic devices and systems within vehicles. These connectors need to meet the strict standards and requirements of the automotive industry, with features such as high-temperature resistance, low-temperature resistance, and corrosion resistance to ensure stable operation in various harsh environments.

In Summary

FPC connectors come in various types, each with its unique characteristics and suitable scenarios. When selecting FPC connectors, it's important to consider specific application requirements, installation environments, and performance needs comprehensively. Furthermore, as electronic technology continues to advance, the performance of FPC connectors will also improve, providing better support for the development of electronic devices.

- +1 Like

- Add to Favorites

Recommend

- Kinghelm FPC Connector KH-FPC1.0-H2.0SMT-30P-QCHF: A Leader in Technological Innovation and Future Prospects

- What are the Popular FFC Connecting Wires Sold by Kinghelm? Such as KH-FFC-V1.0-7P-100MM,KH-FFC-V0.5-15P-150MM

- Kinghelm KH-FG0.5-H2.0-40PIN with 40 Pins at 0.5mm Pitch,Perfect for High-Density, Space-Constrained Applications

- Elevating Communication: The KH-FPC4G-1.13IPEX-100 PCB Antenna from Kinghelm

- Kinghelm FPC/FFC Connector KH-FG0.5-H2.0-12PIN: High-Quality Connection Solution for Electronic Devices

- Kinghelm‘s KH-FAK-K508-P FAKRA Right Angle Connector: Advancing Electronic Connectivity

- Unlocking Seamless Connections: Kinghelm‘s KH-FAK-K509-B RF Coaxial FAKRA Connector

- Future-Proofing Electronics with the Kinghelm FAKRA Gray KH-FAKRA-G-CB RF Connector

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.