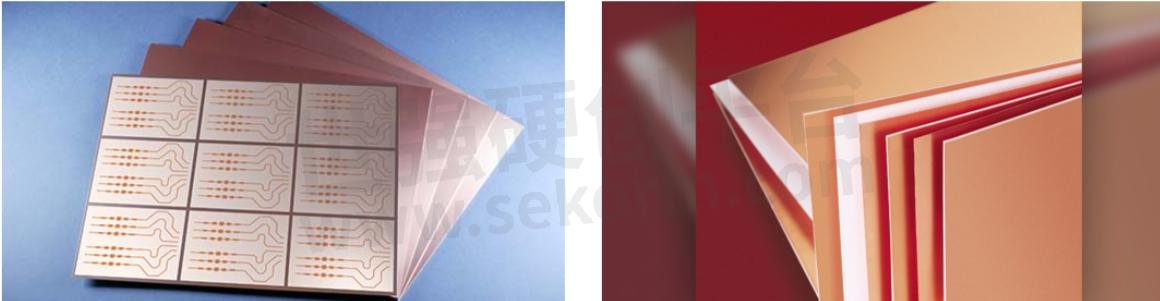

ROGERS Provides Various of Circuit Laminates in Reliable PTFE, Creating Possibilities for Improved Performance

Electronic devices are necessities for many, performing a multitude of daily functions including communicating, remembering appointments, and tracking finances. The printed circuit boards (PCBs) that support those devices must channel a variety of signals which continue to move higher in the electromagnetic (EM) spectrum as bandwidth is occupied. Circuit materials for those PCBs evolve with the demands of electronic applications, enabling circuits at higher frequencies as new combinations of materials are explored and applied. Composite materials for circuit materials are carefully researched for electrical and mechanical behavior under many different environmental conditions and knowing how the different ingredients of a circuit material work together can often ease the task of finding the best circuit material for a particular application.

Polytetrafluoroethylene (PTFE) is one of those essential ingredients for many high frequency PCBs. It is a thermoplastic fluoropolymer formed of carbon and fluorine, with high molecular weight and low coefficient of friction. It has excellent dielectric properties at microwave through millimeter-wave frequencies and has been a reliable foundation for high frequency circuits on land, sea, and in air. But it does not work alone and functions best when combined with other key material components to form composite materials with the electrical and mechanical properties needed for applications. Those different combinations yield circuit materials that can best serve different segments of the frequency spectrum as it continues to be filled by radio waves of all shapes and sizes.

PTFE exhibits dielectric properties superior to many materials, with high dielectric strength and low dielectric constant (Dk). Solid PTFE has a Dk of about 2.0 and extremely low loss tangent or dissipation factor (Df) of approximately 0.0003. It is mechanically sound and chemically inert, with a high coefficient of thermal expansion (CTE). But for all these positive qualities, PTFE is only one material component in a successful high frequency circuit material. It is typically reinforced with woven-glass or ceramic materials to increase the mechanical stability and enhance the thermal behavior of PTFE. When used for PCBs, it is desirable to match the CTE of the dielectric PTFE material to the copper conductors, so that both portions of the PCB expand and contract in the same manner.

By combining PTFE with different material additives, ROGERS has provided the benefits of PTFE to circuit designers, electronic manufacturers, and electronic end-users while also delivering the highest performance and reliability for each composite combination. Whether combining PTFE with glass materials, ceramics, or other fillers, the circuit materials offer a wide choice of electrical and mechanical characteristics to meet the ongoing evolution of electronics technology throughout the frequency spectrum, well into the millimeter-wave frequency range past 110 GHz.

For Rogers’ circuit materials, no matter the composition, circuit designers and fabricators can count on the accuracy and precision of key parameters such as Dk. By adhering to proven industry test methods such as IPC-TM-650 2.5.5.5c, which characterizes the Dk through the thickness (or z-axis) of the material at 10 GHz, users of the materials are assured of Dk and other parameter values that accurately represent the products. Tolerance values are offered for some material parameters, such as Dk, to provide an indication of consistency. In addition, “design Dk” values are available of all circuit materials, allowing circuit designers to account for any variations in material behavior resulting from circuit fabrication processes when using a commercial circuit design software program with circuit material input parameters.

Defining Differences

circuit laminates are compilations of material components, including a foundation such as PTFE. Additives help fine-tune the electrical and mechanical behaviors of the resulting composite material so that critical parameters, such as Dk, can be adjusted according to the needs of circuit designers, fabricators, and applications. For example, in the Rogers RO3000® Series material line, the initial low Dk of PTFE is raised through the addition of ceramic materials, at times with woven-glass reinforcement. While the additives result in a line of circuit materials with a wide choice of Dk values, from as low as 3 to just above 10, those values are all tightly controlled through each circuit panel. The benefits of PTFE are enhanced through these added materials in terms of electrical consistency and mechanical strength, and the tight tolerances of the Dk values are quite impressive.

The lowest Dk value, for example, belongs to Rogers RO3003™ with a process Dk value of 3.00 through the z-axis of the material measured at 10 GHz. The Dk tolerance across the material is remarkable, at a miniscule ±0.04, denoting the impressive control in manufacturing this material from PTFE and other material components. In the case of RO3003, the major added material is ceramic, which accounts for the slight increase in Dk above the nominal Dk of PTFE. For even greater mechanical strength, along with the ceramic material, glass reinforcement is added to Rogers RO3203™ laminate with only a minor increase in process Dk of 3.02 at 10 GHz while maintaining the same tight Dk tolerance of ±0.04.

Higher Dk values enable greater miniaturization of circuit features for a given signal frequency and members of the RO3000 laminate line provide Dk values as high as 10 by supporting PTFE with different blends of ceramic and woven glass reinforcement. RO3035™ laminates, for instance, by adding ceramic material to the PTFE, raise the Dk to 3.50 while keeping a Dk tolerance of ±0.05. By adding a greater amount of ceramic or different types of ceramic to the PTFE, RO3006™ laminates increase the process Dk value to 6.15 while holding the Dk tolerance to ±0.15. The laminate is also available with the mechanical strength of woven glass reinforcement and the same Dk value and Dk tolerance, as RO3206™ laminates. RO3010™ laminates increases the ceramic portion of the PTFE composite to achieve a process Dk of 10.20 with Dk tolerance of ±0.30. It is also available with woven glass reinforcement and the same process Dk of 10.20 but only slightly worse Dk tolerance of ±0.50, as RO3210™ laminate. Tight control of the material amounts in each composite case accounts for the Dk tolerances that are consistently tight even as the Dk value increases. In each case, the quality of the individual materials, including the base PTFE material, is critical for achieving composite Dk values held within such tight windows.

For those who prefer a Dk value as close as possible to the base PTFE value of about 2, Rogers RT/duroid® 5000 RF circuit materials include RT/duroid® 5870 laminate with a process Dk value of 2.33 and RT/duroid® 5880 laminate with a process Dk of 2.20; the Dk values for both materials are maintained across the material with a stunningly tight tolerance of ±0.02. These PTFE-based circuit laminates feature composites with different amounts of random glass fiber to achieve the different Dk values.

As these circuit material examples show, a laminate’s composition contributes a great deal to its performance, but it can also influence the way the circuit material is processed when manufacturing PCBs. While RT/duroid 5870 and 5880 laminates may offer Dk values close to that of PTFE, and outstanding performance at the highest frequencies, they are not overly friendly to circuit fabrication processes, especially when using the processing of low-cost FR-4 circuit materials as a reference. With their composite blends, PTFE-based RO3000 circuit materials, on the other hand, are more compatible with higher-volume circuit fabrication processes.

Of course, PTFE is only one of several base materials forming modern circuit material composite formulations for high frequency circuit laminates. Thermoset materials such as polyphenyl ether (PPE) and polyphenylene oxide (PPO) are also commonly used, along with epoxy resin and hydrocarbon-based materials with ceramic fillers. One of the earliest high frequency thermoset circuit materials, RO4003C™ laminate from Rogers, is a hydrocarbon-based material friendly to high-volume circuit fabrication processes. It features a nominal Dk value of 3.38 with Dk tolerance of ±0.05. With its good plated-thru-hole reliability, the material has proven to be well suited for producing high-layer-count PCBs via FR-4-like processing.

RO4003C laminate is one member of the RO4000® Series line of hydrocarbon-based circuit materials with ceramic and woven glass fillers available with Dk values from 3.25 to 6.15. The lowest Dk value belongs to RO4830™ circuit laminates which are formulated with spread woven glass in addition to hydrocarbon and ceramic materials. For a slightly higher Dk of 3.48, RO4350B™ laminates employ woven glass and ceramic fillers. Both Dk values are maintained within ±0.05 Dk tolerance. At twice the Dk value, at 6.15, RO4360G2™ laminates blend hydrocarbon, ceramic, and woven glass materials into a combination that maintains a Dk tolerance of ±0.15. These thermoset materials are extremely reliable in high-temperature environments and offer FR-4-like ease of high-volume PCB processing, especially for multilayer circuits.

Demand continues to grow for high-performance, high frequency circuit materials as use of the frequency spectrum is expanded well into the millimeter-wave range with such applications as automotive safety systems, 5G communications networks and, before long, 6G networks combining terrestrial and satellite links. The circuit examples presented here demonstrate how compilations of materials can make differences in material behavior, ease of processing, performance, and reliability. New materials and mixtures always create possibilities for improved performance, cost, and reliability as shown by these few examples, Rogers is constantly in quest of material combinations that can lead to a better electronic future.

- +1 Like

- Add to Favorites

Recommend

- Rogers Announces Acquisition of Silicone Engineering

- Sekorm Became an Authorized Distributor of Rogers

- Rogers Announces Termination of Merger Agreement with DuPont

- Rogers Corporation Announces Further Actions to Streamline Operations and Drive Margin Improvement

- Rogers Corporation Announces Intention to Consolidate Manufacturing Facilities for RO3000® and RO4000® Product Lines

- Rogers Corporation Introduces New Water-Resistant Flexible Heater Substrate

- Rogers Expands Capabilities and Services with New Application Laboratory

- Rogers‘ Micro Channel Coolers (MCC) in High Performance Computing (HPC) Applications

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.