Rogers‘ Micro Channel Coolers (MCC) in High Performance Computing (HPC) Applications

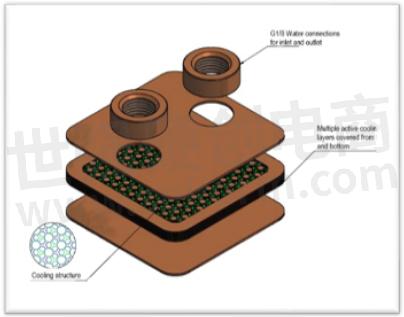

In 2004, and even sometime before the global PC gaming boom started, curamik® engineers from the field of high power laser cooler applications came up with the idea to use our unique Direct Bonded Copper (DBC) technology and developed special microchannel cold plates for CPU cooling. As a result, the curamik® PolarXstream PC-Cooler was born. G1/8 standard connectors for cooling liquid makes it easy for them to adapt to new systems. With multiple active cooling layers, the design can be adjusted to customers' specific needs and purposes based on their performance requirements. Standard and proven cooling structures secure lifetime and efficiency. Even though CPU thermal management is a very interesting application, in today's blog we want to talk about HPC cooling and its needs.

ROGERS PCK 1/1 cooler structure

High-Performance Computing

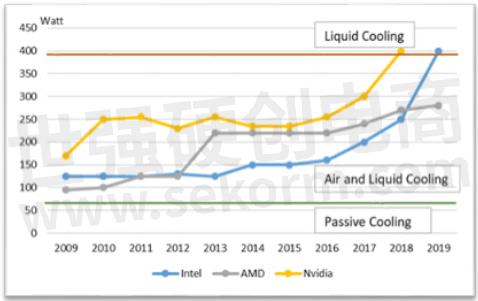

Currently, available cooling solutions have reached their limit in edge and high-performance computing. However, direct chip cooling offers a solution to keep the chip temperatures at an optimum operating temperature. According to forecasts by MarketsandMarkets Inc., the global market for liquid cooling in data centers will grow from $1.2 billion (2019) to $3.2 billion by 2024. This is due to the increasing demand for energy-efficient and compact cooling solutions at lower operating costs and requirements for higher performance from edge to HPC. Conventional rack and room cooling solutions are reaching their limits. One resolution is to use direct chip cooling solutions and Rogers Corporation's microchannel cold plates in order to support your system through the next advancement. Market experts are already testing and/or are using our cold plates.

Own Illustration of HPC chip power development in the perspective of possible cooling options.

Customers

Numerous international HPC providers are among our customer base and driven by COVID 19 impacts, last month's demand for HPC and data centers steadily increased. However, also specialized companies such as MEGWARE are interested in Rogers MCC to fulfill and secure their company goals. “We believe that it is essential to use the available resources sustainably and economically. We develop solutions that significantly cut energy consumption, reduce emissions and thereby actively help protect the environment. Our HPC systems, servers, and workstations are designed for both high performance and energy efficiency.”(MEGWARE, 2021) As HPC systems are usually running 24/7 they can use the heat from the chip to climate buildings and facilities in the surroundings. This saves money for their customers and helps to protect our environment.

©MEGWARE SlideSX®-LC compute platform

Why are Rogers micro-channel cold plates better than others?

Rogers curamik Cooling Solutions offer a wide range of advanced liquid cooling solutions powered by the state-of-the-art curamik bonding process. The layers are hermetically combined without any additional soldering or adhesive. These innovative liquid coolers feature copper foil channel structures (<250-micrometer channel width) that are bonded into a tight block using the curamik process. Compared to standard solutions, Rogers' coolers are up to four times more efficient than traditional liquid cooling module structures. Furthermore, their narrow channels provide a larger highly conductive copper surface area to the cooling medium than many other solutions. This is the secret of Rogers' MCC high performance. If necessary, coolers are integrated with ceramic substrates, enabling direct component assembly and electrical isolation from the cooling circuit.

- +1 Like

- Add to Favorites

Recommend

- Rogers Announces Acquisition of Silicone Engineering

- Sekorm Became an Authorized Distributor of Rogers

- Rogers Announces Termination of Merger Agreement with DuPont

- Rogers Corporation Announces Further Actions to Streamline Operations and Drive Margin Improvement

- Rogers Corporation Announces Intention to Consolidate Manufacturing Facilities for RO3000® and RO4000® Product Lines

- Rogers Corporation Introduces New Water-Resistant Flexible Heater Substrate

- Rogers Expands Capabilities and Services with New Application Laboratory

- A Historic Milestone for Rogers Germany GmbH – Groundbreaking for Production Expansion in Eschenbach

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.