Application of Equipment Heat Dissipation and Thermally Conductive Gel

Some people think that electronic devices will generate heat when they are used, so it is ok to let them not generate heat. However, heat generation when electronic devices are running is inevitable, because in reality the conversion of energy will be accompanied by loss. This part of the loss A large part of the energy is dissipated in the form of heat, so it is not feasible to eliminate the phenomenon of heat production.

Air is also a poor conductor of heat, and the heat transfer rate in the air is slow, so a radiator is needed. Install the radiator on the surface of the heat source of the equipment, and conduct the excess heat from the heat source into the radiator through surface-to-surface contact, thereby reducing the temperature of the heat source. However, there is a gap between the radiator and the heat source, and the heat will be affected by the air during heat conduction. The rate of action is reduced, so a thermal interface material is used.

The thermally conductive interface material can effectively fill the gap between the heat sink and the heat source, remove the air in the gap, and reduce the contact thermal resistance between the interfaces, thereby improving the heat dissipation of the device.

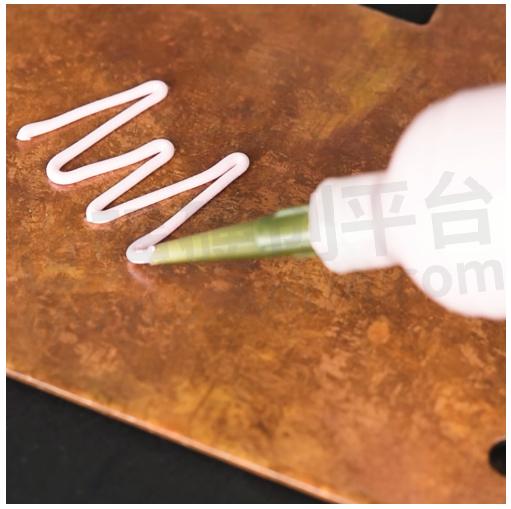

Thermally conductive gel is a member of thermally conductive interface materials. In addition to high thermal conductivity and low interface thermal resistance, the thermally conductive gel itself is a thick and semi-flowing paste. The gap can be quickly filled on the plane, and the thermal conductive gel also has many advantages, such as being applicable to a fully automated production process, convenient storage management, and so on.

- +1 Like

- Add to Favorites

Recommend

- A Brief Description of Thermally Conductive Materials - Thermally Conductive Gel

- Thermal Grizzly CPU Contact Frame Intel 1700 LT is Now Available

- Thermal Grizzly Product Update: AM5 High-Performance Heatspreader with New Nickel Plating

- Why Look for A Thermally Conductive Material with Low Thermal Resistance?

- Thermally Conductive Materials with Ultra-high Thermal Conductivity

- Thermal Grizzly Prepared Four New Products for Intel’s Arrow Lake Processors

- What is a thermally conductive silicone sheet?

- What is the Significance of Reducing Thermal Resistance?

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.