SANYO DENKI Develops Brand New SANMOTION G Servo System That Combines Powerful Performance and User-Friendliness

SANYO DENKI CO., LTD. has developed and released a brand new servo system, SANMOTION G, which features industry-leading(1) servo performance in a compact, lightweight, energy-efficient design. It is ideal for semiconductor manufacturing equipment, machine tools, food manufacturing equipment, and medical equipment.

Features

- Powerful Performance -

1. Evolved Servo Performance

This servo system provides high-speed and high-precision control of equipment, greatly improving productivity and processing quality. The following servo performance ratings have been improved compared to SANYO DENKI conventional products.(2)

Speed frequency response(3): 1.6 times higher (3.5kHz)

Extended output range at high speeds: 1.15 times extended

Positioning settling time: Positioning settling time: 3 times shorter

Encoder resolution: 16 times higher (27-bit, battery-less)

2. Improved Reliability and Maintainability

This servo system has various safety functions to ensure the safety of operators, such as monitoring of power supply status and communication quality, estimation of the remaining life of the holding brake, and prevention of electronic component failures. Also, the battery-less encoder eliminates the need for battery replacement, improving the reliability and maintainability of equipment.

3. Usable in Various Environments

The vibration resistance of the servo motor and amplifier has been improved two-fold and 20%, respectively, compared to the conventional products.(2) The operating temperature range of the servo amplifier has been extended by approximately 10%, covering from 0 to +60°C. This allows the amplifier to be used at a high altitude of 2000 m above sea level. With improved environmental durability, this product can be used in a variety of regions and environments.

- Eco- and User-Friendly -

4. Compact, Lightweight, and Energy-saving

Compared to the conventional products,(2) the motor and amplifier have been made lighter by up to 28% and 5%, respectively, and the overall motor length has been shortened by up to 22%. Furthermore, the energy loss of the motor and amplifier has been reduced by up to 8% and 22%, respectively, and brake power consumption has been reduced by up to 44%. This greatly contributes to the downsizing, weight reduction, and energy savings of your equipment.

5. Easy and User-friendly

A single cable can connect both the motor power and brake connections and the connector orientation can be changed for easy wiring. This product can measure the frequency characteristics of equipment with high precision and optimize servo parameters automatically, making start-up easy. Both the servo motor and servo amplifier are designed to be compatible with conventional products(2) for easy replacement.

(1) Based on SANYO DENKI own research as of May 12, 2022, conducted among industrial servo systems with equal output on the market.

(2) Compared with SANYO DENKI conventional SANMOTION R servo systems.

(3) This frequency indicates how stably the motor can follow a speed command from the servo amplifier. The higher the value, the more precisely the motor follows the command.

Applications

Semiconductor manufacturing equipment, machine tools, food manufacturing equipment, and medical equipment.

Lineup

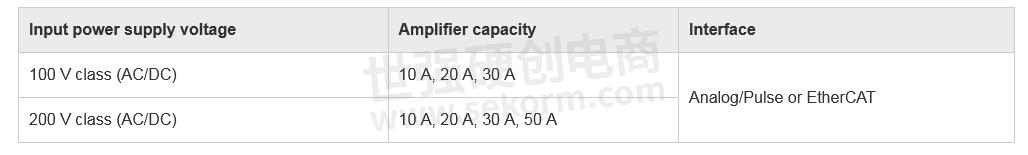

Servo amplifier

Servo motor

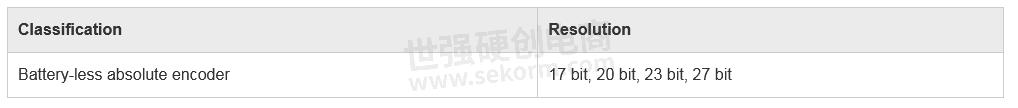

Encoder

- +1 Like

- Add to Favorites

Recommend

- SANYO DENKI Expands Its Lineup of SANMOTION G Servo System, Which Offers “Powerful“ and “Friendly“ Features

- AC Servo Motor System SANMOTION G Received GOOD DESIGN AWARD 2023

- SANYO DENKI Develops SANMOTION C S500 Series Motion Controller That Can Control 7-Axis Articulated Robots

- STO (Safe Torque Off): Maximizing Safety in SANYO DENKI’s Servo Systems

- SANYO DENKI Develops SANMOTION C S200 Motion Controller for Monitoring and Maintenance of Equipment

- SANYO DENKI Develops SANMOTION Multi-Axis Integrated Linear Servo Motor Unit That Simplifies the Assembly Process

- SANYO DENKI Develops Stepping Systems Featuring High Torque and Low Vibration

- 10 Essential OPC-UA Considerations Networking Motion Control

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.