Maxell Has Succeeded in Increasing the Energy Density of A Ceramic-packaged All-Solid-State Battery

Maxell has succeeded in increasing the energy density of a ceramic-packaged All-Solid-State Battery using a sulfide-based solid electrolyte, resulting in a newly developed and a commercialized ceramic-packaged all-solid-state battery that has approximately twice the energy density of its predecessor.

This high-capacity ceramic packaged all-solid-state battery achieved twice the energy density by adopting new technologies regarding structures and processes while maintaining various properties such as the capacity, output characteristics, and heat resistance of the ceramic packaged all-solid-state battery announced in March 2021.

Responding to the requests from FA and infrastructure device manufacturers, Maxell will begin sample shipment of high-capacity ceramic packaged all-solid-state batteries achieving half the volume from August 2022.

With this high-capacity ceramic packaged all-solid-state battery, reliability in a 250ºC environment can be maintained–something that was difficult with conventional lithium-ion batteries–and surface mounting is enabled by reflow soldering. Because of their ability to support smaller sizes and larger capacity, sales of these products will also be expanded to the markets such as those of medical devices (where sterilization is essential), FA equipment, and in-vehicle equipment, as well as those markets where surface mounting is required. Maxell plans to install manufacturing equipment for mass production of the high-capacity ceramic packaged all-solid-state batteries at the Kyoto factory in the spring of 2023.

Main features of high-capacity ceramic packaged all-solid-state battery

●Achieve small and high capacity with approximately twice the energy density (PSB401010H)

●Achieve operating temperature up to 105℃ for 10 years of use

●Surface mountable on board by reflow soldering (maximum temperature of around 250℃)

Maxell has been developing and manufacturing lithium-ion batteries and micro batteries for many years. It is developing an all-solid-state battery with high performance and high reliability by fusing cultivated analog core technologies*5 and other technology from collaboration with other companies, and by adding the newly developed process technology. The company is planning a transition to the quick start-up of mass production of high-capacity ceramic packaged all-solid-state batteries by utilizing factories, equipment, production engineering technology, and know-how for micro and lithium-ion batteries in Japan.

Maxell considers that a rechargeable battery with high heat resistance and long-life performance including high reliability and safety is required for solving future social issues and that sulfide-based solid electrolyte and ceramic packages are important technologies that can greatly improve heat resistance and reliability. Maxell is currently continuing to develop even greater capacity and higher energy density of batteries, in addition to a high-capacity ceramic packaged all-solid-state battery. Maxell believes that such development can contribute to the realization of a maintenance-free society in various fields.

Maxell will continue to improve technology that supports long life and a wide temperature range and will contribute to solving social issues through the continuous productization of high-performance batteries.

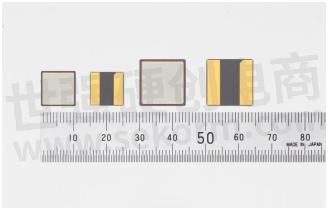

Appearance

and specifications of high-capacity ceramic packaged all-solid-state battery

High-capacity ceramic packaged all-solid-state battery PSB401010H (left) and PSB401515L (right)

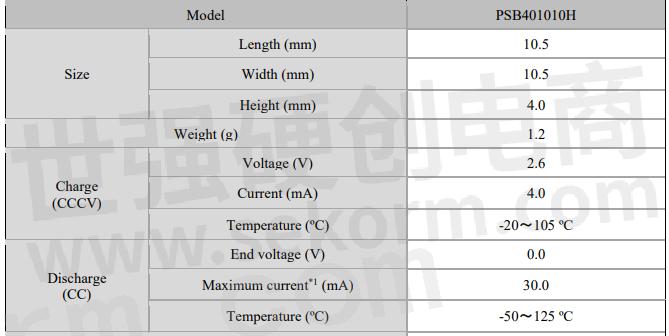

Specifications of high-capacity ceramic packaged all-solid-state battery

- +1 Like

- Add to Favorites

Recommend

- Maxell‘s All-Solid-State Battery PSB401010H Adopted for the Intelligent Image Recognition Unit “iXAM Vision Engine“

- Maxell‘s All-solid-state Battery PSB401010H Adopted for the Intelligent Image Recognition Unit “iXAM Vision Engine”

- Maxell‘s PSB401010H All-Solid-State Battery (Nominal Capacity 8mAh) Was Adopted in Nikon‘s “Multi-Turn Absolute Encoder”

- Maxell Developed Cylindrical All-Solid-State Battery PSB23280 Applied to Main Power Applications

- Maxell Adds the Lineup to High-Capacity Ceramic Packaged All-Solid-State Battery, with Increased Side Length to 15mm

- Maxell Successful Development of Technology that Increases Maximum Operating Temperature of All-Solid-State Battery to 150℃

- Ceramic Packaged All-solid-state Battery That Can be surface mounted to circuit board | Maxell

- ROHM‘s Nano Energy™ and LAPIS Technology‘s Charge Control IC Help Maxell Energy Harvesting-compatible Evaluation Kit

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.