Ceramic Packaged All-solid-state Battery That Can be surface mounted to circuit board | Maxell

Maxell, Ltd. (President and Representative Director: Keiji Nakamura, hereinafter “Maxell”) has developed a ceramic packaged small type All-solid-state Battery that uses sulfide based solid electrolyte (hereinafter “Ceramic Packaged All-solid-state Battery”).

■ Key Features of the Ceramic Packaged All-solid-state Battery

1. Can be surface mounted to circuit board

2. Balances high heat resistance of ≥250°C (482°F) with high sealing properties

Maxell has succeeded in high sealing properties and increased heat resistance, all while maintaining capacity and output characteristics of the Coin-type All-solid-state Battery published in September 2020. The outer packaging is a ceramic package made by KYOCERA Corporation (hereinafter “KYOCERA”). The electrolyte is an argyrodite type high-performance solid electrolyte made in collaboration with MITSUI MINING & SMELTING CO., LTD. (hereinafter “Mitsui Kinzoku”). Ceramic packaging made it possible to secure reliability in a 250°C environment, which has been difficult to achieve with conventional lithium-ion batteries and original product . The Ceramic Packaged All-solidstate Battery can accommodate a broad variety of usage in markets where high heat resistance and high sealing properties are needed, allowing for expansion into new markets in addition to existing markets such as surface mounting by reflow soldering and sterilization treatments for medical devices. The newly developed Ceramic Packaged All-solid-state Battery is to be ready for sample distribution within 2021.

Over the years, Maxell has gained extensive experience in the development and mass production of lithium-ion batteries and micro batteries. Maxell has succeeded in developing 2 high-performance/high reliability all-solid-state batteries by combining the know-how and Analog Core Technologies cultivated from experience, along with technology developed collaboratively with other companies and newly developed processing techniques.

Maxell anticipates a fast shift into mass production of small type all-solid-state batteries by utilizing micro battery factory equipment, production technology and know-how readily available in Japan.

Worldwide shipment quantity of lithium-ion batteries is estimated to be 16 billion by 2025, with the average annual growth rate from 2020 to 2025 estimated at 10%. As the application devices continue to become high-performance, smaller, lighter, and multifunctional, the batteries installed will be required to enhance all-around performance as well. This includes energy density, input-output characteristics, lifetime, heat resistance, reliability, and safety. The all-solid-state battery using Mitsui Kinzoku’s argyrodite type high-performance solid electrolyte is one of very few battery technologies that can simultaneously fulfill these diverse market demands. Additionally, KYOCERA’s ceramic packaging largely enhances heat resistance and reliability, making the technology even more significant in today’s market.

Maxell is thinking beyond the Ceramic Packaged All-solid-state Battery and is currently continuing development in higher energy density.

Maxell currently has 62 patents pending worldwide for technology in relation to all-solid-state batteries, including but not limited to coin type and ceramic packaged all-solid-state batteries.

Maxell will contribute to solutions for societal problems, such as SDGs, through sustainable production of high performing batteries by continuing to design high capacity, high inputoutput, and enhanced technologies to manage a wide range of temperatures.

Appendix

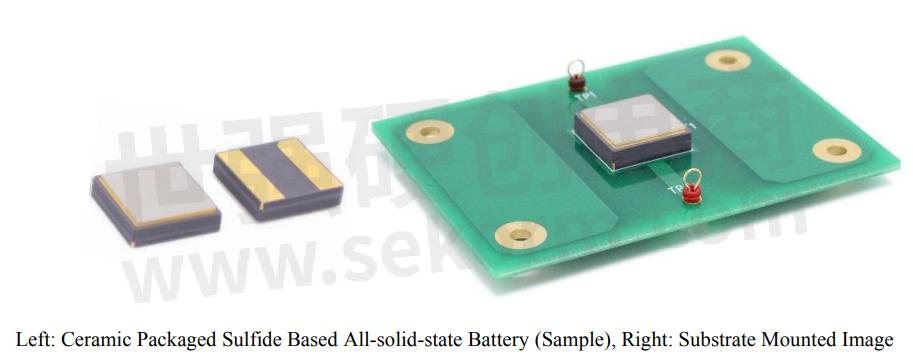

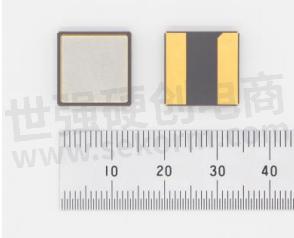

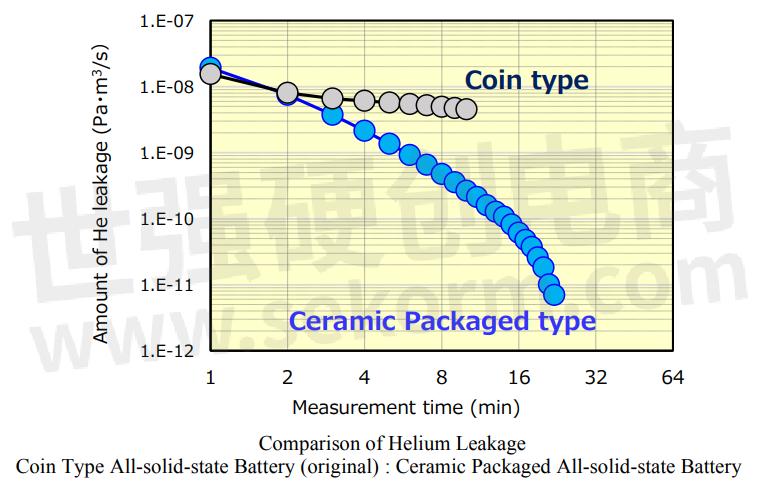

■ Ceramic Packaged All-solid-state Battery’s (sample)Appearance and Specification

Ceramic Packaged All-solid-state Battery (sample) Front (left) & Back (right)

■ Main Characteristics

1. Surface Mounting made possible By employing ceramic packaging made by KYOCERA, surface mounting to circuit boards, which had been difficult for the original, is now possible.

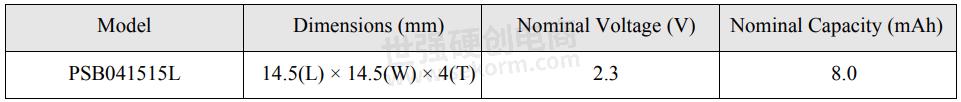

2. Balances high heat resistance of ≥250°C with high sealing properties By optimizing welding conditions, 10-11 (Pa・m3 /sec) was achieved in an after reflow helium leak test. Balance of high heat resistance of ≥250°C with high sealing properties have been actualized, while maintaining high output characteristics of the coin type all-solid-state battery.

- +1 Like

- Add to Favorites

Recommend

- Maxell Successful Development of Technology that Increases Maximum Operating Temperature of All-Solid-State Battery to 150℃

- Maxell‘s All-Solid-State Battery PSB401010H Adopted for the Intelligent Image Recognition Unit “iXAM Vision Engine“

- Maxell Developed Cylindrical All-Solid-State Battery PSB23280 Applied to Main Power Applications

- Maxell Develops CLB640 Coin Type High Capacity Lithium-Ion Rechargeable Battery with a Diameter of Approx. 6mm and Approx. 1000 Charge/Discharge Cycle Characteristics

- Maxell Develops Cylindrical Type Lithium Manganese Dioxide Battery With Industry‘s Highest Capacity Suitable for IoT Devices

- Maxell Has Succeeded in Increasing the Energy Density of A Ceramic-packaged All-Solid-State Battery

- Maxell‘s PSB401010H All-Solid-State Battery (Nominal Capacity 8mAh) Was Adopted in Nikon‘s “Multi-Turn Absolute Encoder”

- Maxell Adds new lineup to Air Patch Battery without harmful or dangerous materials,for medical and healthcare patches and logistics control tags

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.