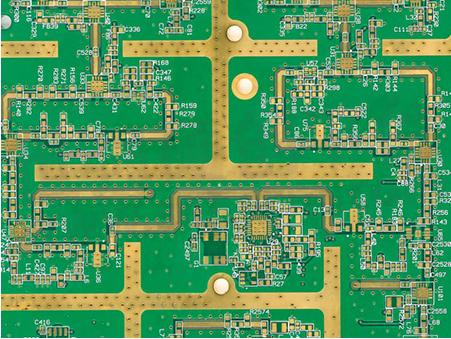

Types of PCB Board Surface Finishes

During PCB board design, considerable attention is given to the PCB layout and the specification of materials, which may include the substrate, laminate, and core for your board’s layer stack-up. These selections are common to all good design for manufacturing (DFM) utilization; however, the many options for PCB surface finish are too often not given sufficient consideration. Instead, the software default is used. Yet, the surface finish is a very important consideration that impacts PCB assembly and your board’s reliability by protecting copper traces and strengthening solder connections. Moreover, there are several types of PCB surface finishes, as listed below :

1. Hot Air Solder Level (HASL)

2. Lead-Free HASL

3. Organic Solderability Preservative (OSP)

4. Immersion Silver (Au)

5. Immersion Tin (Sn)

6. Electroless Nickel Immersion Gold (ENIG)

7. Electroless Nickel Electroless Palladium Immersion Gold (ENEPIG)

8. Electrolytic Wire Bondable Gold

9. Electrolytic Hard Gold

Making the right selection for your design requires an understanding of the differences among the available types.

Which Type of PCB Finish Should I Use?

The best way to answer this question is probably to compare the types of PCB surface finishes against a set of well-defined attributes that will most likely affect your decision. A good list of attributes should include the following :

1. Lead-free solder – Adheres to restrictions of hazardous substances (ROHS)regulations.

2. Handling sensitivity – Susceptible to contamination or breakage from handling.

3. Wire bondable – Capable of forming good wire-bound connections.

4. Tight pitch – Can be used for tight pitch components, such as ball grid arrays (BGAs).

5. Contact usage – Cen the contact be used for contacts.

6. Shelf life – Has good shelf life, and can be stored for six months are more.

7. Additional cost – Typically adds cost to your PCB manufacturing.

Whether your greatest concern is an organic surface finish as opposed to metallic, lead-free solder instead of lead-based, or turnaround time, SDY Electronic can assist you in making the best selection among the many types of surface finishes available for your design. As industry leaders in precise, high-quality, and fast PCB manufacturing, our primary motivation is to ensure that you have the best experience and achieve your desired results.

- +1 Like

- Add to Favorites

Recommend

- Heat Dissipation Application of Thermal Interface Material in PCB board

- The Role of Thermal Gel and the Heat Dissipation Application of PCB Board

- Selection of Fuses in Small Home Appliance PCB Board

- Managing the Impact of PCB Material Properties on Your Board‘s Manufacture

- SanDeYing Electronic PCB 3D Models Provides A Clear View of All The Parts on PCB Boards in 3 Dimensions Length, Width, and Height

- IS6630A/C/D with Three-way Output Enables DDR Power Supply Integration, Saving the Space on the PCB Board And the Required Devices

- Self Recovery Fuse on Mobile Power PCB Board

- One of The Most Widely Used Pcb Layout Software:Altium Designer Preferences Setting

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.