NOVOSENSE Gauge Pressure Sensor Enables The Liquid Level Detection of Household Appliances More Intelligent and Energy-saving

Liquid level detection is an important part of the functions of many household appliances. For example, washing machines and dishwashers require multi-water-level washing by controlling liquid level for water saving; the water heater requires automatic refilling of water when the liquid level is too low to prevent dry heating; coffee machine and beer machine requires liquid level detection to control the flow and water yield. Therefore, accurate liquid level detection is an important premise and guarantee to realize the relevant functions of household appliances. The NSPGD1 launched by NOVOSENSE Microelectronics is a calibrated gauge-pressure liquid level sensor, which can meet the needs of highly accurate liquid level measurement of household appliances and make household appliances more intelligent.

NSPGD1 eliminates the application pain point

The traditional liquid level measurement is mechanical and photoelectric, which can only simply measure the presence or absence of liquid or roughly measure the liquid level, and cannot achieve high-precision and stable measurement. However, the built-in signal conditioning chip of the integrated MEMS pressure sensor integrates temperature compensation and linear compensation, which can eliminate the defect of low precision of traditional liquid level measurement.

NSPGD1 is a series of calibrated gauge-pressure sensors for the home appliance market. It adopts a high-performance signal conditioning chip to calibrate and compensate for the temperature and pressure of the MEMS piezoresistive die, ensuring performance and reliability while integrating the package for easy operation.

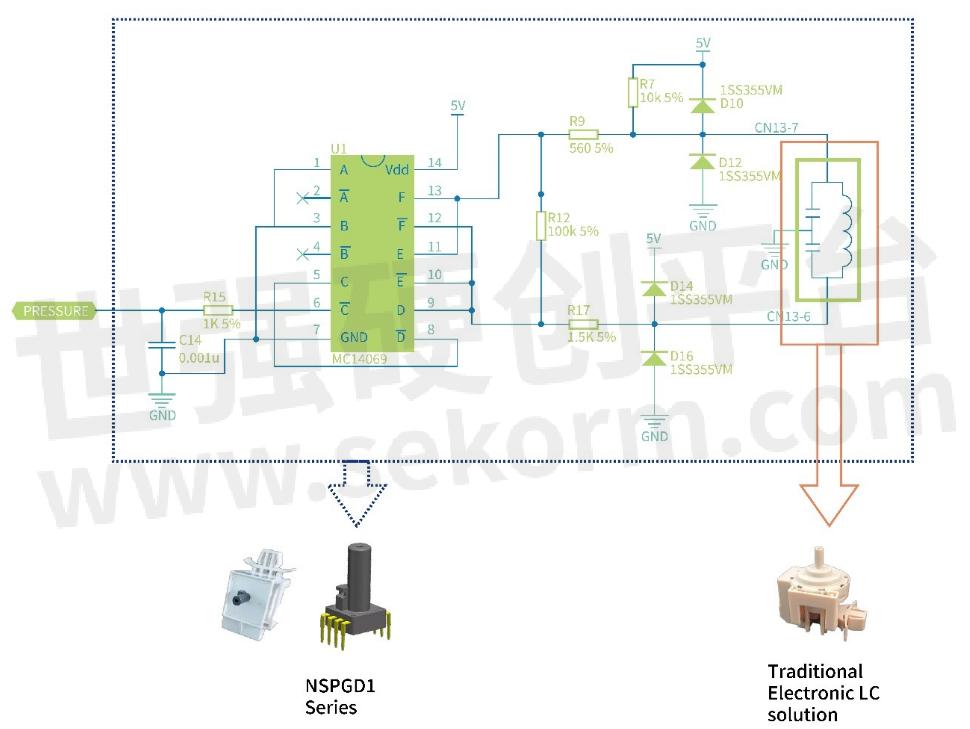

Comparison of NSPGD1 and traditional electronic water level meter

To sum up, NSPGD1 has four advantages. First, compared with the traditional mechanical water level measurement solution, the MEMS pressure sensor chip features high output accuracy (comprehensive accuracy up to 1% in full temperature zone), high linearity, and high integration, without too many peripheral devices, which helps to reduce the overall size, circuit complexity and cost of the solution, and increase the flexibility of the design. The unique frequency output mode and 5.45mm diameter nozzle facilitate the seamless replacement of the water level sensor of the traditional mechanical washing machine, which is an ideal choice for upgrading the water level monitoring function of the washing machine.

Devices replaced by NSPGD1

Second, NSPGD1 adopts NOVOSENSE high-performance and high-reliability MEMS piezoresistive technology for seamless domestic replacement, and compared with similar products, it has higher output precision, lower power consumption, wider operating temperature range, and stronger resistance to bursting pressure. Compared with foreign N/S/M on the market, NSPGD1 features a wider temperature range, lower working current, more abundant packaging forms, lower cost, and higher cost performance. Third, NSPGD1 expands the product portfolio of the NOVOSENSE pressure sensor series, which can meet the pressure detection requirements of small and medium range (0 ~ 2kPa) in the segmented field. Fourth, as a domestic chip provider, NOVOSENSE can better guarantee delivery and reduce the risk to customers' supply chains.

NSPGD1 series integrated pressure sensor

The NSPGD1 series integrated pressure sensor is available in a range of -10kPa to 10kPa (which can be customized) and comes in a DIP8 package with an air nozzle for easy soldering and use.

It is suitable for gauge pressure detection of non-corrosive gases compatible with pressure-sensitive components, non-contact liquid level detection, industry, IoT, and other fields. The series supports analog output /I2C digital output and unique frequency output functions for more flexible applications.

The output pressure of NSPGD1 has a linear relationship with the liquid level height, and the output can be detected in real-time without cumulative error. It can be used for accurate measurement of drip, leakage, and flow loss, directly replacing the traditional mechanical liquid level sensor, and can replace the rotor flowmeter for flow and volume measurement in the system with a fixed diameter. Its peripheral interface circuit is simple with a variety of optional data output forms for convenient application.

Features and applications of NSPGD1

NSPGD1 series integrated pressure sensors have the following product features:

High accuracy and low power consumption: It features high linearity and good stability without calibration, with 100% temperature compensation and better device consistency, output accuracy higher than ±1%F.S. at normal temperature, full temperature range accuracy higher than ±2%F.S. at 0℃~70℃, and operating current less than 3mA.

Multiple output modes: Support three output modes, analog output/digital I2C output/frequency output, which is suitable for a variety of applications, simple and convenient with good portability.

Package with air nozzle: The standard model comes with a DIP8 package (10.4mm×10.4mm), and supports front air intake without blockage, the inside of the chip is waterproof and moisture-proof, with high reliability and stress relief characteristics.

Pressure range can be customized: A range of -10kPa ~ +10kPa can be customized, and it supports a variety of pressure application scenarios with high flexibility.

NSPGD1 series integrated pressure sensor is mainly used for accurate measurement of liquid level height. It is an integrated pressure gauge sensor with an air nozzle based on silicon piezoresistive effect advanced MEMS micromachining process. The package with the air nozzle is especially suitable for the liquid level detection of household appliances such as washing machines, water purifiers, and dishwashers, and can also be used for medical electronic equipment such as massage chairs, intelligent sphygmomanometers, oxygen generators, ventilator, oxygen generator, anesthesia instrument biosafety cabinet, as well as a pressure switch, negative pressure vacuum detection, gas pressure detection, and other industrial control, Internet of Things and other fields of pressure detection applications.

Functional block diagram of NSPGD1 (I2C output)

The design scheme of liquid level detection based on the NSPGD1 pressure sensor

NSPGD1 uses a MEMS piezoresistive gauge pressure core as a pressure-sensitive element, which outputs an original signal output proportional to the ambient pressure. The sensitive element is driven by a built-in conditioning chip, which conducts the original signal amplification, temperature compensation, and linearity compensation, and then outputs a voltage signal with a linear relationship to the applied pressure. The NSPGD1 series supports analog/digital output (I2C) as well as unique frequency output.

NSPGD1 analog output form

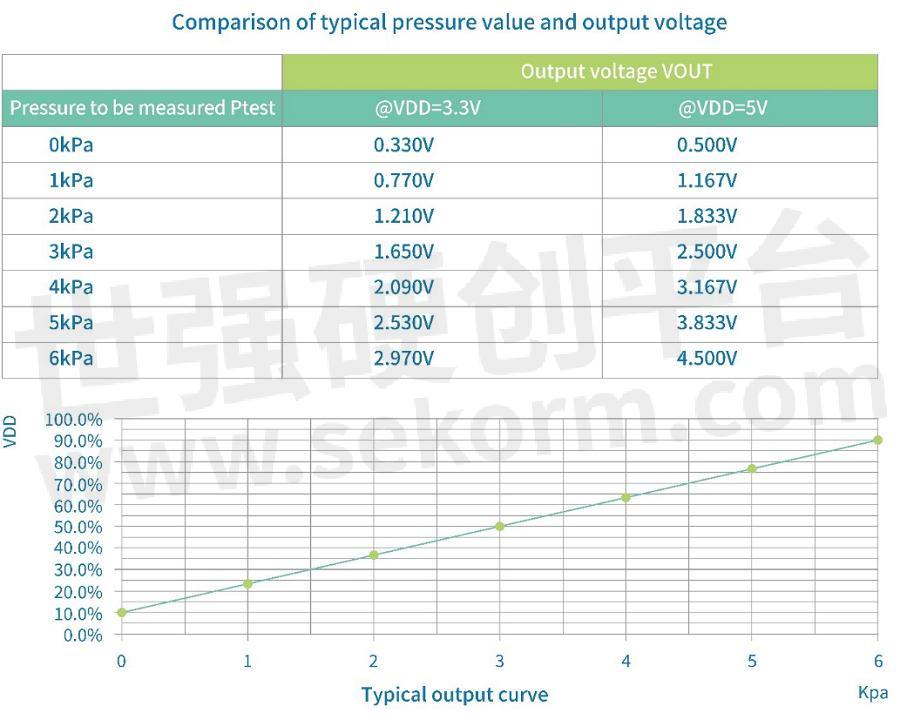

Taking proportional output mode as an example (output voltage value is the percentage of power supply voltage), this series of analog output chips are for the range of 0kPa ~ 6kPa, and Pmax is 6kPa (output 90%VDD), Pmin is 0kPa (output 10%VDD), and its typical transfer function is:

Where:

Vout is the output voltage, in V;

VDD is the input voltage, in V;

Ptest is the pressure to be measured, in kPa.

The following table compares typical pressure values with output voltages.

Typical input/output diagram

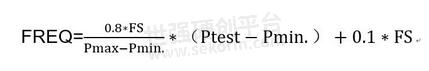

NSPGD1 frequency output form

This series of frequency output chips are for the range of 0kPa ~ 6kPa, and Pmax is 6kPa (output 90%FS), Pmin is 0kPa (output 10%FS), and its typical transfer function is:

Where:

FREQ is the output frequency, in KHz;

FS is the full-scale value of frequency output, in KHz; the chip can be configured with a maximum frequency of 250KHz;

Ptest is the pressure to be measured, in kPa;

NSPGD1 digital (I2C) output form

This series of digital (I2C) frequency output chip is for the range of 0kPa ~ 6kPa, and its typical transfer function is:

Where: Pdata is the value collected by I2C;

The specific processing steps of digital (I2C) output data are as follows:

Power on the chip;

1. I2C writes register 0x30 to 0x0A;

2. Wait for 3ms;

3. I2C reads register values 0x06, 0x07, and 0x08 continuously, assuming that the read register values are data1, data2, and data3 respectively.

Follow these steps below to convert the register values of 0x06 (data1), 0x07 (data2), and 0x08 (data3) to Pdata

1. D1=data1*65536+data2*256+data3;

2. If D1>8388607, Pdata=D1-16777215;

3. If D1≤8388607, Pdata=D1;

Example:

If the values of registers 0x06, 0x07, and 0x08 are 0x15, 0x55, and 0x56 respectively, follow the above steps, D1=1398102, and the value of D1 is less than 8388607, then Pdata=1398102, P (Pa) = 500, and finally the pressure value is 500Pa.

The liquid level detection solution in this document is the NSPGD1 pressure sensor based on I2C digital output form. To realize analog volume or frequency output mode based on NSPGD1, please contact NOVOSENSE.

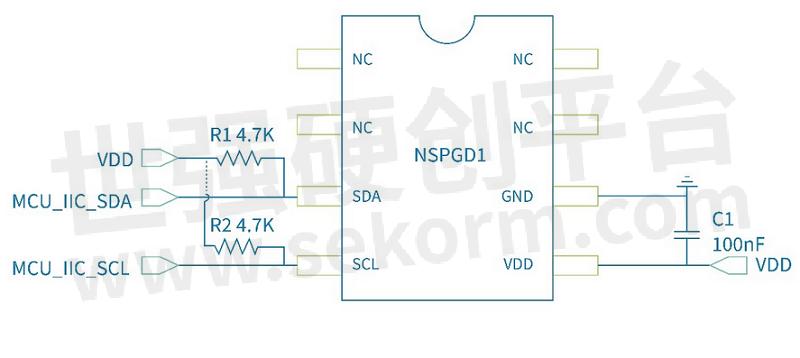

The following is the application circuit diagram of I2C serial bus communication in this document. The I2C series bus generally has two signal wires, one is bidirectional data line SDA, and the other is clock line SCL, both of which are pulled up to VDD through 4.7K pull-up resistance, and GND and VDD have 0.1μF filtering capacitor.

Circuit diagram of NSPGD1 I2C output-type application

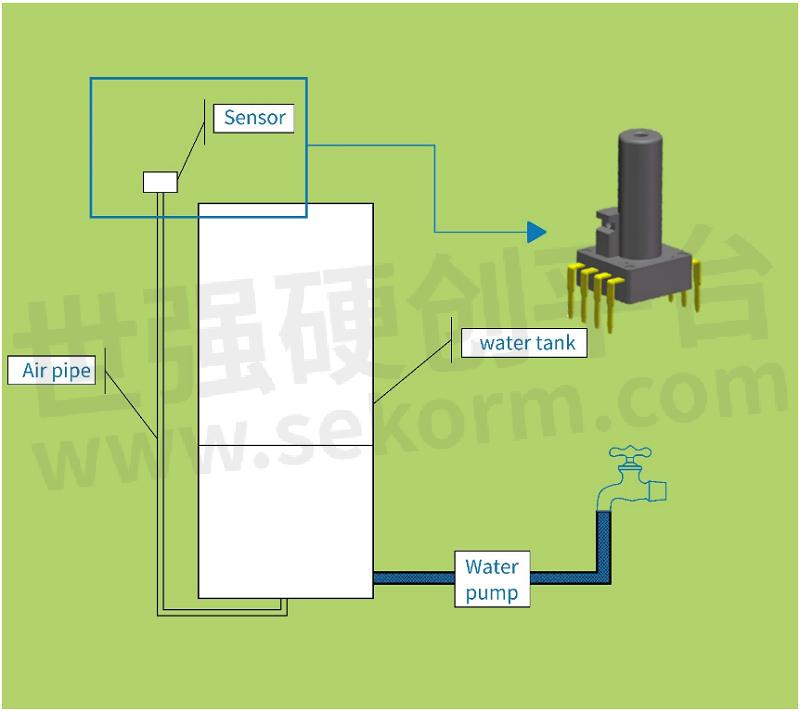

Reference application structure

The following figure shows the NSPGD1 reference application structure. The NSPGD1 sensor is connected to the bottom of the water tank through the air pipe. The rise or fall of the water level in the tank will correspond to the change of liquid pressure in equal proportion. The NSPGD1 high-precision sensor can be used to obtain the liquid height in the tank in real-time, and then realize automatic water supply or transport according to the control logic of different household appliances.

NSPGD1 reference application structure

Sensor data processing

The liquid level detection solution in this document is the NSPGD1 pressure sensor based on I2C digital output form. The calculation method of sensor measurement data and liquid height is as follows:

Method 1: Pressure to height conversion:

P_f is the pressure generated by the liquid at the bottom of the tank; ρ is the density of the liquid; ρ is 1.0*10^3kg/m^3, assuming that the liquid bucket is water; g is the gravitational acceleration of 9.8m/s; h is the liquid height, then the liquid height h can be obtained by the following formula:

If the sensor range is 0kPa ~ 6kPa, the h range of the corresponding measured liquid height is 0 ~ 0.612.24m. Considering that the actual gas pipe is installed at the bottom of the liquid tank; after storing water, part of the water will enter the air pipe, and this part of the water will form a certain pressure in the air pipe, resulting in the whole drift of the zero point. Therefore, it is necessary to compensate for the zero-point pressure in the actual application. Due to the different inner diameter and installation position of the air pipe, the specific offset value needs to be obtained by actual test:

Method 2: Direct calibration conversion:

By directly measuring the relationship between the liquid level height h of the calibration vessel and the sensor Pdata, the transfer function of the actual height h and Pdata is obtained, and the liquid level height is calculated by Pdata, thus avoiding the error introduced by the conversion of intermediate pressure.

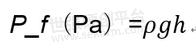

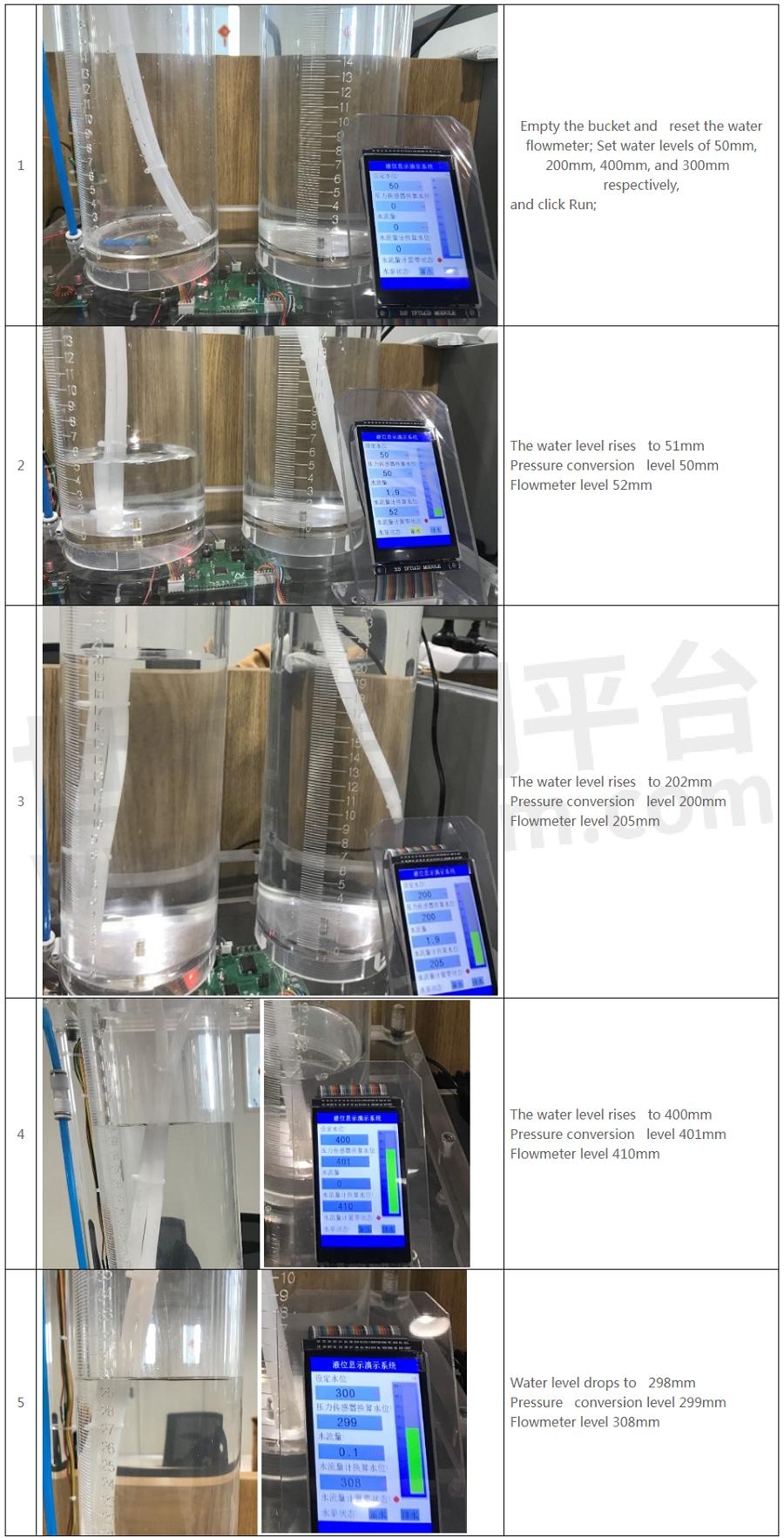

Comparison test of NSPGD1 application and water flowmeter

A comparison test of the NSPGD1 application and water flowmeter is shown in the table below.

Comparison test of NSPGD1 application and water flowmeter

Test the 4 test points with water level height set to be 50mm, 200mm, 400mm, and 300mm in the above table to obtain the results of a comparison test of the NSPGD1 application and water flowmeter shown in the table below:

As can be seen from the above table, the accuracy of measurement results of NSPGD1 is higher than that calculated by the water flowmeter. In the four test points: The measurement error at 50mm is the largest, which is -1.96% (absolute error of 1mm), but the water level at this time is low, and the error accounts for a significant ratio of water level height at this time. In the full range, based on the real-time measurement of liquid pressure, NSPGD1 measurement results will not accumulate errors, the data is more balanced, and the liquid level height error is 1 ~ 2mm. After running for a long time, the error of the flowmeter becomes larger due to the accumulation error of pulses. The maximum measurement error is 2.68% and the absolute error reaches 10mm.

The single NSPGD1 sensor measurement accuracy is 0.5%. However, the errors of the whole DEMO system include the system errors introduced by such factors as the uneven scale of the acrylic liquid barrel, unreliable air pipe connection, visual observation, and vibration caused by liquid flow. Therefore, the errors of liquid level height in practical applications can be controlled by reasonable arrangement, installation, and algorithm compensation.

Conclusion

The liquid level detection scheme based on NSPGD1 uses fewer peripheral devices, has high precision, and can realize monitoring in real-time for non-contact measurement of liquid, and the measurement results are free of cumulative error. NSPGD1 is a type of sensor that can be customized with different ranges according to different customer requirements, helping to meet the requirements of different household appliances on liquid level height measurement.

- +1 Like

- Add to Favorites

Recommend

- NOVOSENSE Has Launched Multiple Automobile-qualified Chips with Breakthrough Innovation Technology In the first half of 2022!

- NOVOSENSE Sensor Solutions for Portable Medical Devices Ensure the Health of Yourself and Your Family Members

- NOVOSENSE Assists the Formulation of LIN Transceiver Chip Standard, Promoting the High-quality Development of the Automotive Chip Industry

- NOVOSENSE Won VDE Premium Quality Award for High Quality Development

- NOVOSENSE Released a New 1200V Series SiC Diode with Typical Fowrard Voltage of 1.39V, Contributing to the SiC Ecosystem

- NOVOSENSE NST1002 Temperature Sensor Facilitates Accurate CGM Measurement with Glucose Monitoring Black Technology

- NOVOSENSE‘s New Isolation Voltage Sampling Chips NSI1312x Series Support +1.2V Bidirectional Linear Input Voltage

- Novosense Selects Tower Semiconductor for Volume Manufacturing of their Magnetic Sensor for the Automotive On-board Charger Market

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.