Boyd Develops Cooling Solution for The Critical SuperCam Assembly of The Perseverance Mars Rover

Boyd's Thermal Management Solution for the SuperCam Assembly Critical to the Perseverance Mars Rover

As NASA prepares for the launch of the Perseverance Rover, planned for July 22nd, 2020, Boyd Corporation is proud to highlight our contribution to the next stage of Mars exploration, developed in collaboration with Los Alamos National Laboratory. Overcoming harsh environments when exploring another planet challenges even the best engineering teams to ensure electronics can and continually operate in varying and unfamiliar conditions. Preparing to explore the Martian surface required creativity, determination, innovation, and perseverance.

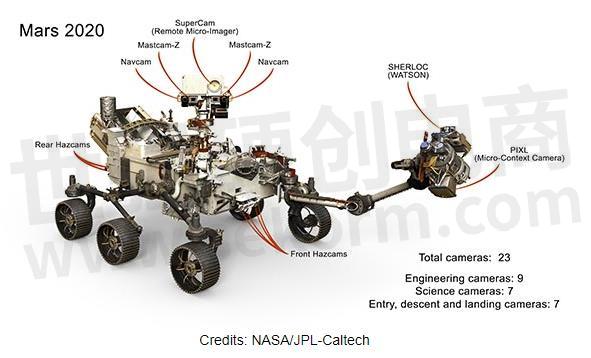

The SuperCam Module of the Perseverance Mars Rover

NASA’s Perseverance Rover mission is to search for signs of previously or currently habitable conditions on Mars and for signs of past microbial life. The SuperCam utilizes remote-sensing techniques to conduct minerology analysis of both the environment and samples within the robotic-arm workspace. The SuperCam is a technological improvement over Curiosity’s ChemCam, as it adds two new techniques for determining mineralogy a color imager, and an acoustic system to remotely determine physical properties of targets.

The SuperCam includes a broad range of spectroscopy instruments, some of which utilize Thermal Electric Coolers (TECs) that use the Peltier effect to pump heat away from electronics and maintain tight temperature control. The TECs need to reject heat to help protect the electronics vital to minerology observations.

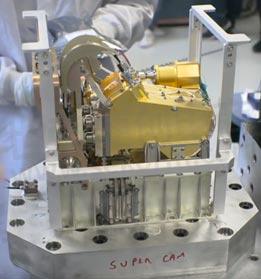

Custom Cryogenic Heat Pipes to Withstand Martian Environments

Heat pipes are a common component in many electronic assemblies used to either spread or transport heat. Many applications use heat pipes to prevent heat build-up and potential damage to sensitive and expensive equipment by quickly moving heat away to cooler regions. While most heat pipes are robust and straightforward; customizations and material selections enable these straightforward solutions to solve more complex challenges, applications and operating environments.

For the Perseverance Rover, maintaining a safe operating temperature of data collection equipment is paramount to the success of the rover. There is no way to do maintenance and repair to the Rover once it’s launched, so thermal management solutions must reliably perform in extreme temperatures common on Mars over the entire lifetime of the rover. Failure is not an option. Boyd’s heat pipes are an ideal solution for space applications like these as they’ve been proven to operate consistently over decades of operation with no active moving parts.

Mars is much colder than Earth but there is less atmosphere, so natural convection air cooling is much slower making electronics at risk of overheating despite the colder environment. This colder environment makes common copper-water heat pipes unsuitable for the Mars Rovers. To solve the performance and environment challenge, Boyd uses our Material Engineering expertise to feature methanol as an alternative working fluid for passive two-phase cooling, which doesn’t freeze at Rover temperatures.

Boyd has previous experience fabricating solutions for Mars missions, making us a solid partner in developing reliable thermal management solutions that meet the demands of reliably performing on Mars. We leveraged our understanding of Martian environment design challenges to create a new heat pipe solution in partnership with Los Alamos National Labs for the SuperCam module. The SuperCam module enables critical imaging, mineral, and chemical analysis, a central portion of the Perseverance Rover mission.

Los Alamos National Labs approached Boyd to help transport a total 6W of heat away from the charge-coupled devices (CCDs, optical detectors) within the SuperCam Module to be transferred to thermoelectric coolers (TECs). As a team, LANL and Boyd developed three heat pipe assemblies to cool 2W each, constructed with two 5mm diameter plated copper-methanol heat pipes. This enables a stable ~20°C of cooling below the temperature of the Rover Accessory Mounting Plate (RAMP).*

One Company, Many Solutions for Space Exploration

Thermal Management is only one of Boyd’s strengths when it comes to supporting space exploration and aerospace applications. From our flame-resistant SOLIMIDE® Insulating Foams to EMI/RFI Management, Boyd can help protect your equipment and cargo in the demanding environments of space with thin atmospheric conditions. Other Engineered Material solutions like Optically Clear Adhesives and High Performance Gaskets protect camera and sensor lenses, sealing and protecting against harsh external environments.

Boyd strives to provide quality, reliable solutions to all industries, but it is a privilege to support the Perseverance Rover and be a part of NASA’s mission to explore Mars. Our long tradition of providing highly engineered thermal management solutions for space exploration will enable the Perseverance Rover to endure for years to come.

- +1 Like

- Add to Favorites

Recommend

- Delta’s High-efficiency Heat Transfer Solutions--Slim Heat Pipes and Slim Vapor Chambers

- Heat Pipes Versus Vapor Chambers: What‘s the Difference?

- The Innovation for 4 heat Pipes CPU Radiator of High Cooling Performance 220W

- Boyd Loop Heat Pipes Set to Launch with NASA’s PACE Mission

- What is the Difference Between a Thermosiphon and a Heat Pipe?

- Aavid‘s Liquid Cooling Systems: Modular or fully customized liquid cooling optimized for improved heat dissipation in condensed volumes

- Turn Your Dissipated Heat into Electrical Energy for a Self-Sustainable Remote Process Monitoring System

- Nextron Heat Dissipation Capabilities and Solutions

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.