Nextron Heat Dissipation Capabilities and Solutions

As we pursuit higher data transmission rate and larger power transmission, heat dissipation is a significant topic that should be taken care of along the way. In order to ensure safety and reliability of Nextron connection products, Nextron has been investing heavily in heat dissipation R&D abilities.

From component to system level, Nextron leverages excellent thermal simulation capabilities and delivers unique designs, machining and system assembly services to provide customers with the most efficient and safe thermal solution.

1. Component Level

Thermal Solutions for I/O Connectors

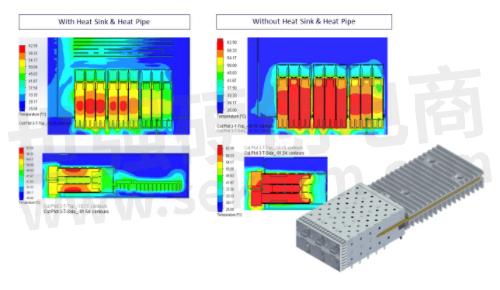

◇ Air Cooling

Heat sinks and heat pipes are custom designed with space limitation and target temperature in consideration.

Special mechanical design and material selection for excellent heat dissipation.

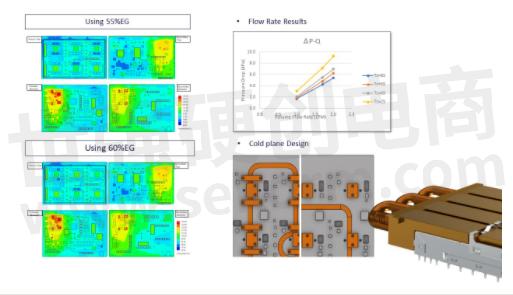

◇ Liquid Cooling

Dissipating up to 20W/pole in different configurations.

Custom design available to configurate with water channel within the chassis.

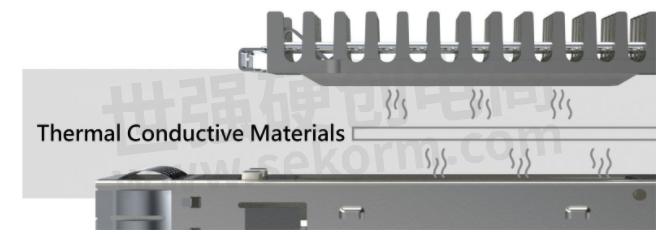

◇ Thermal Conductive Material and Additions

Thermal conductive materials, thermal pads / tapes and thermal interface coatings under development.

Case :

◇ Air Cooling Solution for CPU

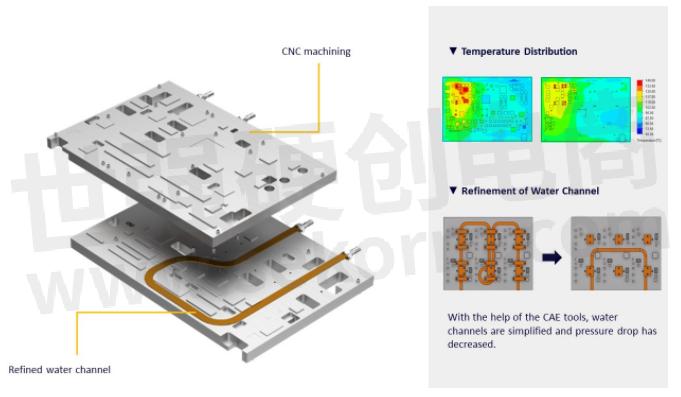

◇ Cold Plate for Sensor Box

With simulation and machining ability, Nextron configures water channels according to customer's PCB design.

2. Compact System Level

Case :

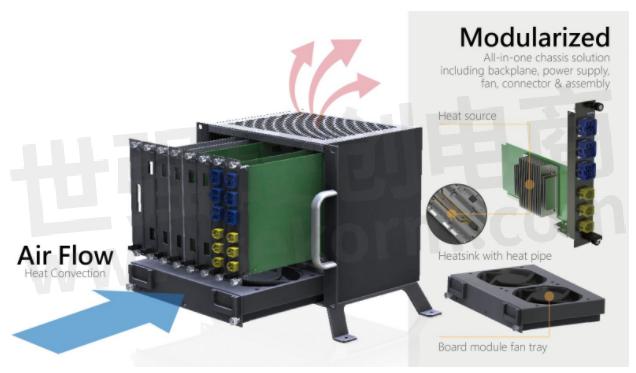

◇ Air Cooling Solution for Compact Chassis

Modularized: All-in-one chassis solution including backplane, power supply, fan, connector & assembly.

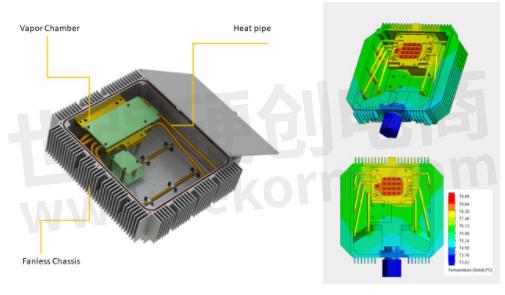

◇ Heat Dissipation Chassis for 5G Antenna

Highly integrated heat pipes with machined aluminum shell for chip arrays.

Perfect balance signal integrity and heat dissipation for outdoor environment.

3. Total System Level

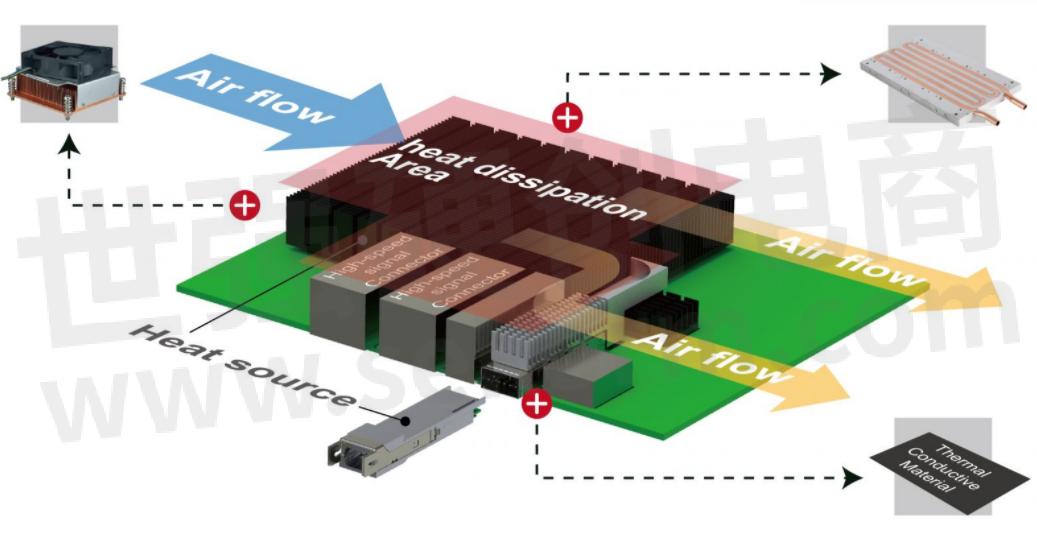

Heat Dissipation Solution for Data Center

Not just single components, appropriate components are selected base on system level simulation to reach target temperature in compact space.

Simulation Capabilities

Thermal Analysis Tools

Software: Solid Works Flow Simulation 2020

Number of engineers: 2 (6-years experience)

Verification Equipment

Easy verification set: Ceramic heater and test chassis

Quality analysis center: Thermal cycle tester, humidity chamber

Case :

◇ Air Cooling Flow Simulation

Leverage system available space, in-system air flow simulation with the customized heat sink/heat pipes reached the target heat dissipation.

◇ Liquid Cooling Flow Simulation

Liquid flow simulation generated optimized design.Only 55% EG of coolant could reach 5.0 kPa pressure drop which allows liquid flow through all channels.

- +1 Like

- Add to Favorites

Recommend

- Nextron‘s SFP families I/O Connectors can Support Up to 50G while Data Rate can Reach Up to 400G for Backhaul Transmission

- The Difference between FFC Connectors and FPC Connectors

- DIN EN 1100 Certified WSMP® Coaxial Connectors, 45% Smaller than Standard SMP Connectors

- What is the Role of Industrial Connectors? What Types of Industrial Connectors Can Be Divided into?

- The Development of High-Voltage Connectors

- ept Colibri® 0.5 mm-pitch SMT Connectors Colibri® 0.5 mm-Pitch SMT Connectors: Maximum Flexibility with Data Transfer Rates of Up to 16 Gbps

- Sekorm Becomes Top Connectors Manufacturer Phoenix Contact Authorized Distributor to Carry Its Full Line Products

- What will be The Development Trend of Connectors in the Future?

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.