The Increasing Threat of Electromagnetic Interference, Analysis of EMI/RFI filtering More and More Important

Electromagnetic interference (EMI) also called radio-frequency interference (RFI) is a disturbance generated by unwanted electrical signals from electronic devices or natural occurrences which can have harmful effects on equipment. These unwanted signals may reduce the performance of the equipment and can even stop it from functioning. These disturbances can occur in various flight-critical applications including communication and military flight control systems, medical applications, and telecommunications.

Design engineers need a way to filter out the unwanted electrical signal, so it doesn't harm additional components. In order to protect modern electronic systems from the abundance of EMI sources in today’s environments, a combination of approaches are implemented: shielding, filtering, and reduction of EMI at the source (if possible). This blog focuses on filtering methods of the signal.

Design Concepts for EMI filter Connectors:

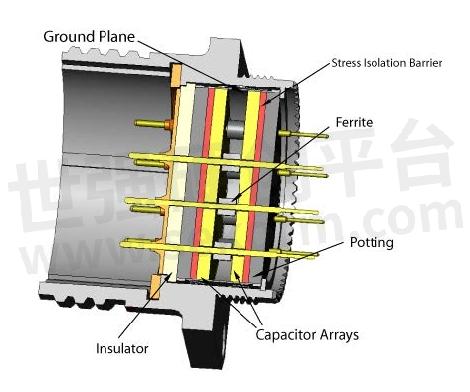

Sophisticated filter connector technology addresses EMI/RFI filtering, and transient protection to meet demanding high intensity radiated field (HIRF) requirements. EMI filter connectors use multi-layer ceramic capacitor arrays together with inductive materials to realize robust, high performance low pass filter networks. Where required, protection can be provided against high energy transients from direct lightning strikes, standard EMP, high altitude EMP (HEMP), non-nuclear EMP (NNEMP) and electromagnetic interference (EMI).

Types of EMI Filter Capacitor Technologies

Tubular Capacitors

Capacitor takes the form of a cylinder with axial leads

Tubular capacitors were the first to be incorporated into EMI filters

Not available in higher capacitance values

Can fail quickly in extreme shock and vibration environments

Cannot withstand higher voltages due to wall thickness

Tubular capacitors still have a significant market share, but are being phased out

Chip Capacitors

These capacitors mount on the surface of the PCB

Much greater range of capacitance values compared to tubular capacitors

Can be removed and replaced from the PCB to modify the capacitor value with minimal cost

Less susceptible to shock and vibration compared to tubular capacitors

Has a resonance frequency of 120 MHz, may be problematic for some applications

Low cost and easily to source

Planar Capacitor Array

This capacitor is constructed out of a ceramic disk

Disk can contain different capacitor values for each pin, unfiltered (feed through) pins, and ground pins

Best technology to use in high shock and vibration environments

Lowest rate of failure

No resonance frequency

Can handle up to 1000 VDC working voltage

Advantages of EMI Filter Connectors:

A single capacitor array can provide multiple capacitance values

Most space efficient method of packaging EMI/RFI and EMP transient protection

Connector shell protects capacitor array & diodes from environmental, mechanical and thermal damage

Transient voltage suppressors integrated into the connector offer EMP transient protection to sensitive circuitry

System weight is reduced by integrating the filters and diodes into the connector

Modular design techniques reduce the overall package size and improve maintainability

Monolithic capacitor arrays are the most reliable method of EMI/RFI filtering

Tested and documented using automatic test equipment

Plug and go solution

Transient Protection using Surface Mount Technology (SMT) Diodes:

Where required, transient suppression can be combined with EMI/RFI filtering to provide maximum protection. Transients are temporary spikes or surges in voltage that can impact components or circuits to the point of failure. Transient protection solutions can be embedded within the filter connector shell by utilizing SMT diodes. The incorporation of SMT diodes can offer space and weight savings to a varying degree dependent on connector application requirements.

Advantages of Surface Mount Technology (SMT) Diodes:

Significant reduction in board space and connector weight

Low incremental surge resistance

Fast response time, typically less than 1.0ps

Low Zener diode impedance values

Better thermal conductivity for high power dissipation requirements

Increased flexibility in design limits

Increased mean time between failures (MTBF)

Improved shock and vibration resistance

EMI filter connectors use multi-layer ceramic capacitor arrays together with inductive materials to realize robust, high performance low pass filter networks. The diodes as well as the EMI filter are packaged separately so the construction of the connector remains modular.

- +1 Like

- Add to Favorites

Recommend

- Knowles Precision Devices Introduces the SFSW Series of Hermetic, Panel-Mount EMI Filters

- The Role of EMI Filters in Power Electronics

- What Goes into a MIL-SPEC COTS EMC-Input Filter for a DC-DC Converter

- Advantages of Smiths Interconnect EMI Filter Connector and Filtered EMP Connectors

- High-Performance Capacitors from Knowles to Meet the Needs of Demanding Aerospace and Defense Applications

- TAH450 Series AC/DC Power Supply Has 450 Watts Output Power and High Performance Integrates PFC, EMI filter

- Filter Capacitor Comparison

- Smiths Interconnect Offered Isolators to Support NASA’s Europa Clipper Mission to Explore Jupiter’s Moon

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.