What Goes into a MIL-SPEC COTS EMC-Input Filter for a DC-DC Converter

The switching action of DC-DC converters can cause undesired common-mode and differential-mode noise, creating interference at unacceptable levels at many points along the frequency spectrum. Front-end (or power-line) filters are intended to be used before DC-DC converters to mitigate electromagnetic interference (EMI). These can be custom-designed or purchased off the shelf to enable a design with a vendor’s switched mode power supply (SMPS) or DC-DC converter to meet electromagnetic compatibility (EMC) regulatory standards for conducted and radiated emissions (e.g., FCC, ETSI, CISPR, MIL-SPEC, etc.).

These off-the-shelf front-end filters are custom-designed, based on the electromagnetic signature of the power conversion equipment. However, an additional level of electrical (e.g., voltage spikes, ripple), mechanical (e.g., vibration, shock), and environmental (e.g., high altitude) design constraints must be considered in order to meet the needs of military equipment. This article discusses the design considerations of front-end filters and the testing requirements for military-grade equipment DC-power modules.

What is a front-end filter?

The design of this input filter is critical in order to meet electromagnetic compatibility (EMC) standards and targets. Front-end, or input filters, are used for multiple purposes:

Suppressing noise and surges that might enter the first stage of the power supply and,

Decreasing emitted noise at both the fundamental frequency (i.e., switching frequency) and its harmonics

Switched-mode power supplies are increasingly utilized in electronics and come with rich spectral content that could both conduct to other parts of the circuit through physical contact and interfere with sensitive circuits nearby. Noise becomes an increasing concern with higher switching speeds, particularly where transistors that turn on and turn off rapidly can cause interruptions in current flow (which leads to voltage spikes and high-frequency noise). These interruptions in current flow can be found at the input side of buck converters, at the output side of boost converters, and at both the input and output of flyback and buck-boost converters.

Noise sources in various voltage regulators

The input side of the DC/DC buck converter features rapid turn-on and turn-off of their switching devices, causing discontinuous currents that have sharp rising and falling edges (high di/dt) on the input capacitors. This will result in the fundamental frequency and several harmonics (often the low-order ones) falling out of compliance. A boost converter operating in continuous conduction mode (CCM) will experience EMI at its output due to the need for fast reverse recovery diodes which, while greatly reducing power losses, will have a much more aggressive change in current (di/dt) and will increase EMI. In discontinuous conduction mode (DCM), the primary current ripple is greater. The ripple will create a varying signal that is conducted to other parts of the system through conductors that share a common contact.

EMI: Radiated and conducted emissions

Generally conducted emissions are associated with frequencies below 30MHz, whereas radiated emissions generally fall into frequencies beyond 30MHz (often 50 to 300MHz). There are, however, still overlaps between both conducted and radiated emissions. In a switched-mode power supply, voltage surges (high dV/dt) are typically sources of radiated emissions. As stated earlier, conducted EMI typically stems from discontinuous current (high di/dt) and can be broken down into both common-mode (CM) and differential mode (DM) noise.

Differential- and common-mode noise

DM currents are generally dominated by di/dt and will flow between the power supply line and the return path; DM noise dominates lower frequencies. It generally is difficult to change the behavior of di/dt without fundamentally changing the circuit. The reduction of di/dt is typically accomplished through the use of a passive low-pass EMI filter (e.g., R-C snubber, L-C, Pi-section, T-section, etc.) to dampen oscillations caused by discontinuous currents.

CM currents are generally a function of dV/dt and will flow between each of the power lines and ground. When CM currents couple into long conductors or cabling, the cabling can act as an antenna that makes CM noise more dominant at high frequencies. Depending on cable length and the distance between conductors and the reference ground plane, the loop area for unintended return paths can be considerably large. CM can be suppressed significantly with effective layout design like moving conductors closer to a reference ground plane, carefully deploying safety capacitors, shielding connected cable harnesses, or placing a CM choke in the path of CM currents. A CM choke also provides a high-impedance series path that allows CM currents to flow out of the converter with Y-capacitors that form a shunt path to EMI ground.

Both DM and CM will contribute to EMI and, oftentimes, both DM and CM noise components need to be quantified before designing the EMI filter to meet industry EMC standards. Input EMI is typically quantified using a line impedance stabilization network (LISN) at the device under test (DUT’s) input as well as a spectrum analyzer.

Design considerations of front-end filters

Generally, passive EMI filtering is the most common approach for noise mitigation; however, it can prove difficult when the filters are terminated with varying noise sources in an SMPS and different load impedances. These filters are generally various arrangements of resistors, capacitors, and inductors. The magnitude of the fundamental component and the first couple of harmonics is the largest and will contribute the most to the overall noise, while the magnitude of higher-order harmonics will taper off as frequency increases. The filter’s ability to attenuate these noise components also rises over frequency, so mitigating noise at the fundamental frequency and lower-order harmonics is a prominent design challenge.

Generally, large passive filters mitigate the lower-frequency emissions; however, higher-frequency emissions might require additional design considerations due to their parasitic nature (e.g., a capacitor’s equivalent series resistance and inductance (ESR/ESL) and an inductor’s parallel capacitance). Other EMI filtering techniques often involve active components: one such technique is using spread spectrum, or dithering, to modulate the switching frequency of the power supply to reduce the peaks found in the frequency domain at the fundamental frequency and low-order harmonics. Ultimately, the technique deployed depends upon the unique noise signature of the SMPS as well as the cost, size, and regulatory constraints on the design.

Beyond meeting EMC regulatory standards, EMI filters may also contain the ability to attenuate high-current transients that are reflected from the load to the input power of the SMPS. The predicted transient characteristics of each SMPS will vary and, therefore, a custom design is often required to sufficiently suppress surges. This is certainly an additional design consideration for MIL-SPEC power electronics. Military-based equipment will come with a slew of electrical, mechanical, and environmental design considerations that cause manufacturers to carefully design power electronics from the ground up -- materials vetting and electrical, mechanical, and harsh environmental performance requirements must all be met.

A look at common military standards for power supplies

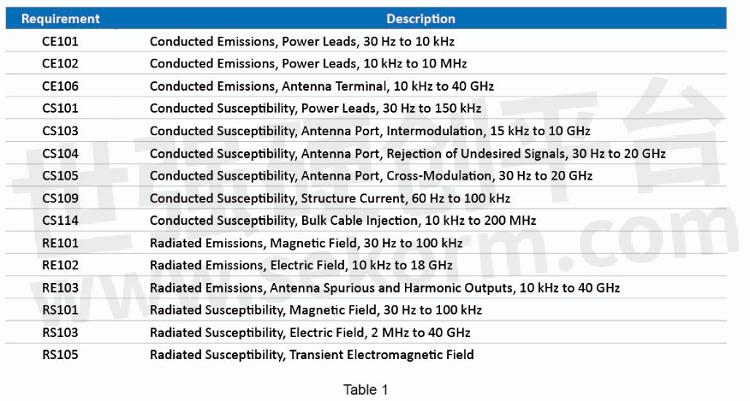

The MIL-STD-461 sets conducted and radiated emission limits on electrical equipment with guidelines for properly measuring EMI. If the SMPS exceeds these limits -- and it often does -- it will require an EMI filter to bring it “back into spec.” However, choosing any off-the-shelf EMI filter will not necessarily cause the power supply to suddenly conform to standard requirements; the equipment can be so noisy that tacking on any EMI filter to the input still causes the part to fail. The various requirements of MIL-STD-461 and their descriptions can be found in Table 1. Electronic equipment that meets the MIL-STD-461 will typically list out the specific CE, CS, and RE requirements met.

EMI is not the only consideration in regard to the proper performance, reliability, and safety of electronics. Power supplies must also be able to operate under various voltage conditions including reverse polarity, voltage spikes, and voltage surges. The MIL-STD-1275E standard provides the test conditions to be applied to the input of a 28V electrical power system, as well as the expected performance parameters of said equipment. These systems are expected to be in military ground vehicles, civilian off-road vehicles, as well as military and civilian heavy equipment.

Other military standards -- such as the MIL-STD 704F standard for aircraft electrical power characteristics and the DO-160G for Airborne Equipment -- will specify the environmental conditions and test procedures to adequately simulate various voltage conditions. The MIL-STD-810 standard includes test conditions and requirements for equipment that will undergo mechanical shock, vibration, and high altitudes. These may also be necessary considerations to ensure the longevity and reliability of the supply in harsh environments. Power supplies operating in military vehicles and in airborne systems will likely need to meet the MIL-STD-1275E/MIL-STD 704F, MIL-STD-461 and aspects of MIL-STD-810 to be deemed suitable for use. P-DUKE offers a line of MCF MIL-SPEC front-end filters that can be matched with select DC/DC converters to meet all of these specifications.

P-DUKE MCF series

The MCF series provides both EMI filtering and transient protection to meet conducted emission, conducted susceptibility, and radiated emission requirements per the MIL-STD-461G standard, surge/spike requirements found in numerous military standards, and altitude/shock/vibration requirements in MIL-STD-810 (Table 2).

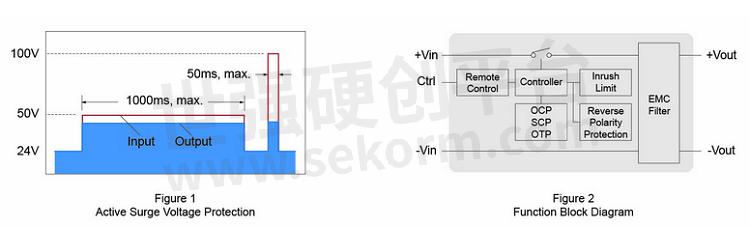

The series offers active input over-voltage protection which clamps over-voltages up to 100V with a maximum duration of 50ms to a safe level of 40V and absorbs +/-250V spikes with the internal protection circuits (Figure 1).

As shown in Figure 2, the series includes other active protection functions, such as remote on/off control, overload protection, output short-circuit protection, reverse polarity protection, inrush current limitation, and more.

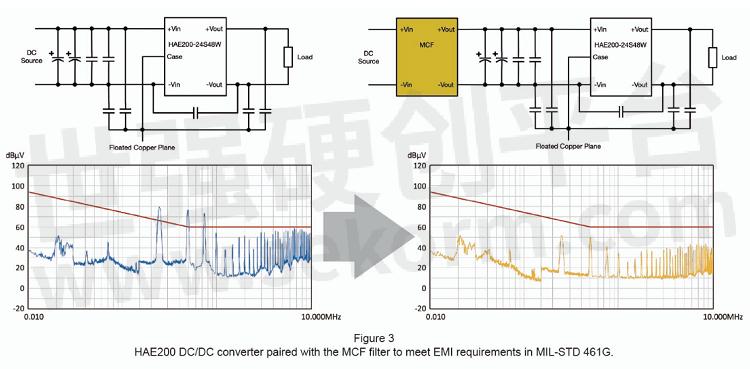

Considerable EMI improvement can be seen in Figure 3, where the 200W HAE200 DC/DC converter’s EMI performance was tested before and after applying the MCF filter. This greatly reduces the cost and design effort that comes with a custom EMI filter and peripheral circuits. With a rated power of up to 250W, the MCF front-end filters can be leveraged for a wide range of military equipment.

MCF filters allow for seamless integration into military systems

EMI filters cannot simply be arbitrarily selected to allow a power supply to fall into compliance, and the process of designing these filters can be quite complex with a high non-recurring engineering (NRE) cost. This is especially the case with military-grade equipment where onboard subsystems in military vehicles and aircraft that are powered by a 24V battery or 28V generators have stringent requirements on multiple dimensions where COTS equipment and custom solutions may not be viable. P-DUKE offers DC-DC converters in a range of 15W to 250W that, when matched up with the relative MCF front-end filters, will meet military requirements for EMC and surge suppression.

- +1 Like

- Add to Favorites

Recommend

- P-DUKE MCF Series Highly Integrated DC/DC Front-end Filters Accepting 9-36Vdc Input Voltage for Military and Rolling Stock Applications

- P-DUKE Latest Safety Standards Update: Edition 3.2 IC/EN/UL60601-1 Declaration

- [Techno Frontier 2024 TOKYO] Visit P-DUKE !! East Hall No.3G-01

- P-DUKE Product EOL Announcement---DOS10-05T & DOH10-05T / DOS16-05T & DOH16-05T

- Visit P-DUKE at the CMEF 2024

- EOL Announcement--- P-DUKE LED15-xxS3P3 / LED15-xxS05

- P-DUKE launches the QAE and HAE ultra-wide input series DC-DC for supply interruption and change-over

- [Electronica 2024 Germany - München] VISIT P-DUKE!! Hall A4 No. 458

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.