Embedded World 2023 Recap: Showcasing the Power of Helium Technology and ARM® Cortex®-M85 in AI and DSP Applications

These demos showcased the ARM® Cortex®-M85 core's capabilities in AI and DSP applications, demonstrating the potential to significantly improve performance in embedded systems.

People Detection Demo in Partnership with PlumerAI

The first demo shown in Figure 1, developed in collaboration with PlumerAI, demonstrated a person detection application built on the Cortex-M85 core. This vision AI application identifies and tracks people in the camera frame under varying lighting, environmental conditions, and a wide range of camera angles with a detection distance of over 20 meters. Utilizing compact and efficient TinyML models, the application enables low-cost and low-power AI solutions for a wide range of IoT implementations.

Figure 1. Person detection demo using the Cortex-M85 core with Helium

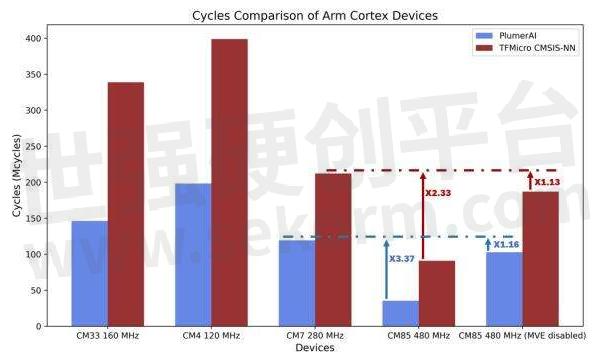

Cycle comparison for a variety of microcontrollers measured on real silicon is shown in Figure 2. Indeed the Cortex-M85 core outperforms the rest of the cores at a significant margin using the open-source TensorFlow lite for microcontrollers [TFLM] inference engine and even further with PlumerAI’s inference engine. Another observation is that most of the performance uplift stems from the utilization of Helium MVE technology.

Figure 2. Benchmark results for person detection demo, Cortex-M85 core attains up to 3.37 better performance than the Cortex-M7 core. Note that the graph compares the cycles, in milliseconds, the uplift would have been around 70% higher due to higher CPU frequency.

Benchmark results displayed a significant uplift in performance over other M-cores, allowing for more complex vision use cases such as person tracking. Faster inference speeds also mean the CPU can return to sleep mode more quickly, resulting in ultra-low power consumption.

Motor Control Failure Detection Demo

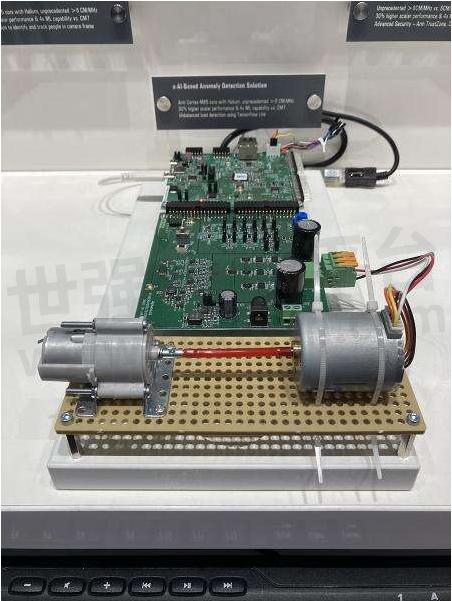

The second demo (Figure 3) showcased a predictive motor control failure detection use case that can be utilized in a wide range of industrial applications. Utilizing the shunt current, the model can predict how much the motor is misaligned (by adding force onto the motor board) and presented on Renesas’s developed GUI.

Figure 3. Predictive motor failure demo with Cortex-M85 core

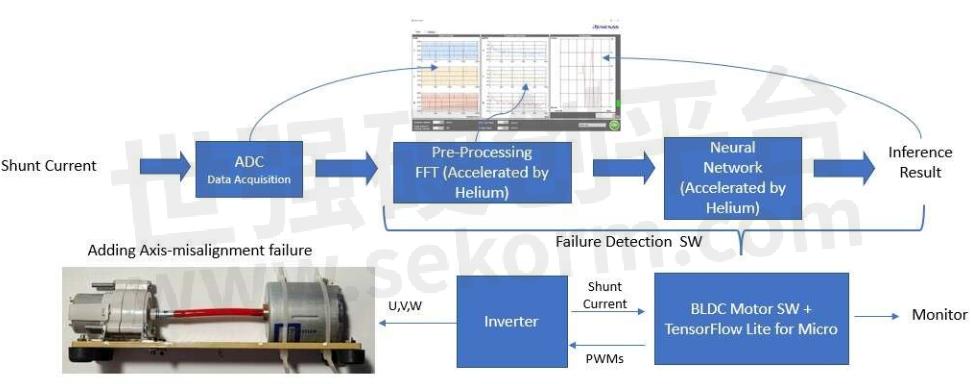

The motor failure detection pipeline shown in Figure 4 uses the shunt current acquired via ADC, preprocesses it with FFT (accelerated by Helium), and employs a convolution neural network (also accelerated by Helium) that is run via TFLM with CMSIS-NN.

Figure 4. Motor failure demo application workflow

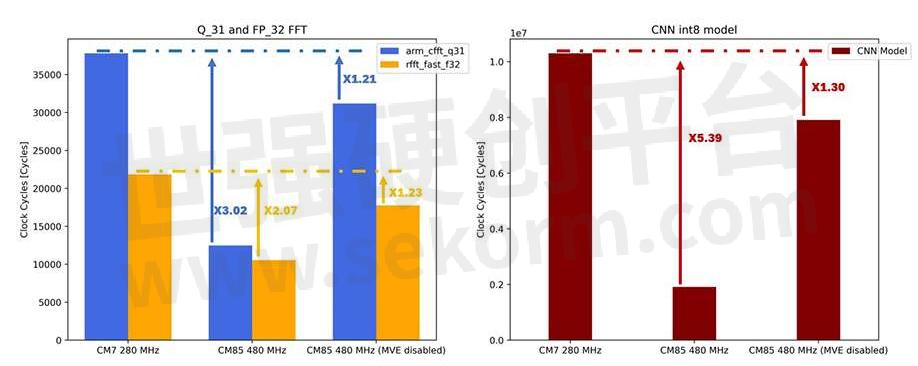

This demo showcased an incredible uplift of over 5 times in the utilized model and an FFT uplift of over 3 times for fixed point format and 2 times for the floating-point format due to Cortex-M85 native support to various data types, as can be seen in Figure 5. The uplift demonstrates that not only Cortex-M85 with Helium is a powerhouse for TinyML applications, but it can also be utilized to replace low to mid-tier DSP accelerators, thus reducing BOM.

Figure 5. Real silicon cycle performance of Cortex-M7 core vs Cortex-M85 core with/without Helium. Note that the graph compares the cycles, in milliseconds the uplift would have been around 70% higher due to higher CPU frequency.

In conclusion, the Cortex-M85 core demonstrations at Embedded World 2023 highlighted the potential for significant performance improvements in AI/ML and DSP workloads. As a result, the Cortex-M85 core with Helium is well-suited for complex processing tasks in embedded systems, enabling the development of more advanced applications and solutions.

- +1 Like

- Add to Favorites

Recommend

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.