What Are the Orientation Options and Advantages for Connectors?

What are the orientation options for connectors?

PCB orientation is the relative position of two PCBs to be connected by BTB connectors. Here are some of the common orientations of BTB connectors:

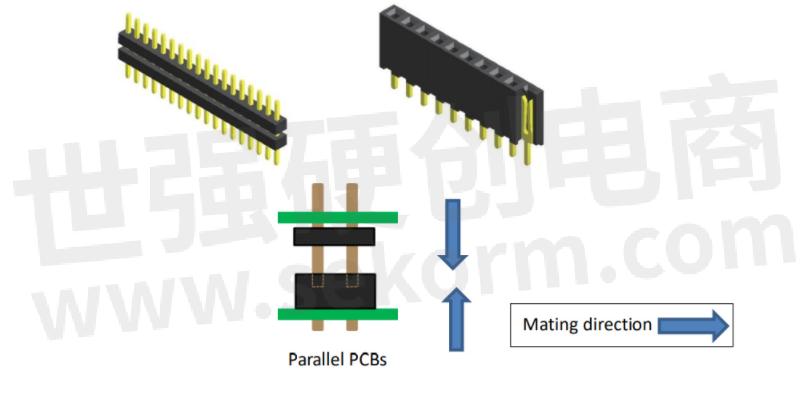

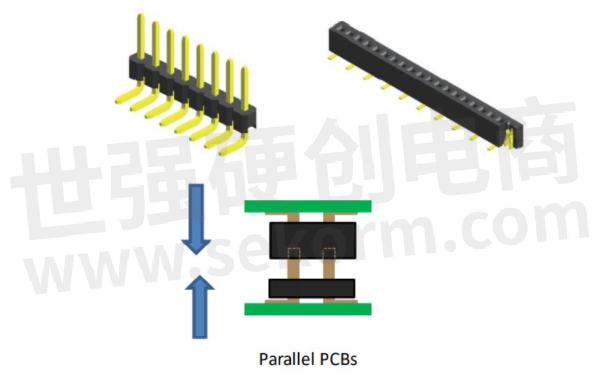

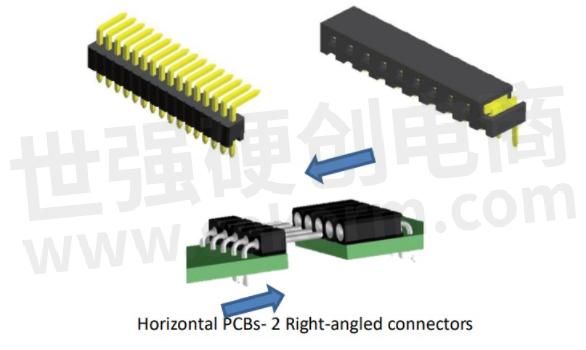

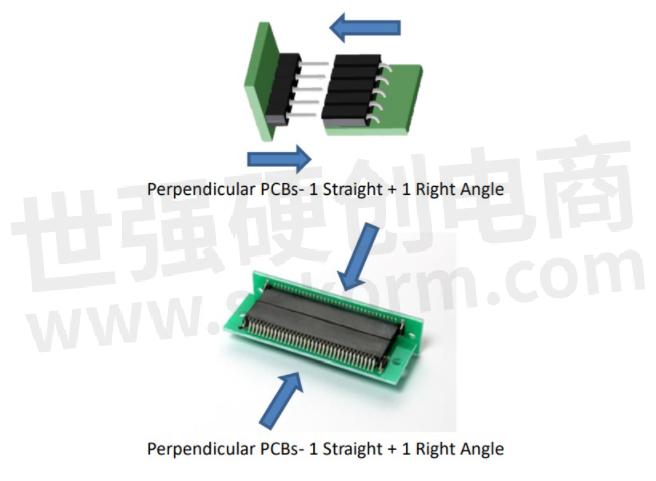

In order to cater to various PCB orientations (Parallel, Horizontal, Perpendicular), board-to-board connectors have been developed in straight, right angle, and U-shaped designs.

· Straight connectors mate vertically on the PCBs. When PCBs are oriented in parallel, we use Straight connectors.

Straight (Through-Hole) Type:

Straight (SMT) Type:

·Right-angled connectors mate horizontally on the PCBs. When PCBs are oriented horizontal, we use Right-angled connectors.

Right-angled (Through-Hole) Type:

Right-angled (SMT) Type:

·Lastly, a combination of straight and right-angled connectors can connect PCBs that are perpendicular to one another.

Why do we stack PCBs?

Amid the trends of miniaturization, lightweight, and high speed, designers often face many constraints, both mechanically, and electrically. Different stacking options offer different advantages.

Vertical - Parallel, Mezzanine - Both connectors are in a vertical orientation. It allows one to stack on top of the other one, minimize the surface area as a result.

Horizontal - 180 Degree, Coplanar, Edge-to-Edge - Both connectors are in horizontal orientation. From the design standpoint, this keeps the mating centerline low profile to the PCBs.

Perpendicular - Motherboard to Daughterboard - Connectors are perpendicular to one another. This is commonly seen in hard drive applications that one can stack many “Daughterboards” onto one motherboard, expanding the data storage space efficiently.

Here are some other advantages:

The design can be modularized into smaller PCBs and the PCBs can be connected by BTB connectors later through the assembly. This not only improves the design process but also allows modifications to be easily done, separately.

From the assembly perspective, it can improve the manufacturability of the product, by operating with smaller PCBs rather than one large PCB.

Stacking the PCB layer properly can enhance the EMC (Electromagnetic Compatibility) of the design.

- +1 Like

- Add to Favorites

Recommend

- How to Select Board-to-board Connectors?

- Function and Parameter Selection of Board-to-Board Connectors

- Inspection and Connection Troubleshooting of Board-to-Board Connectors

- Features and Classifications of Board-to-Board Connectors

- Basic Performance of Board-to-Board Connectors

- Production Process of Board-to-Board Connectors

- Classification and Characteristics of Board-to-Board Connectors

- Intro to Plastic Insulators of Board-to-board Connectors

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.