Renesas Will Respond to The Customer‘s Expectation for xEV Electrification by State-of-art IGBT!

In this post, let me introduce the xEV market status in Europe, where one of the most active areas, and our promotional activities.

The power device is one of the key parts which contributes to the Electrification in xEV, which is just in the drastic variation once in a century. Then, what/how can Renesas support our customer (OEM/Tier1/Tier2) with differentiation towards the upcoming explosive ramp-up??

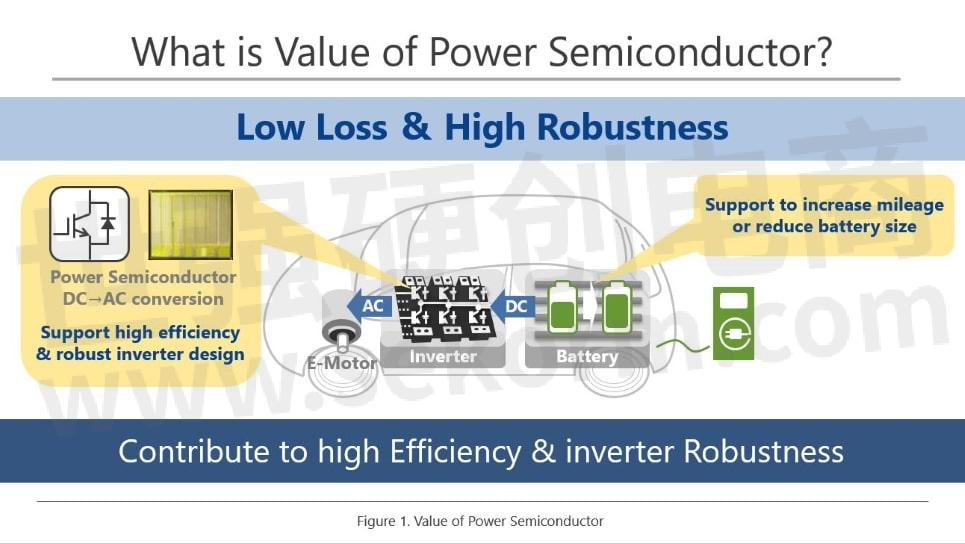

Customer's Expectation 1: "High efficiency" & "Hard to break" car design!

· Power consumption: The lower power loss device (= higher efficiency) in the motor inverter directly supports to enable Li-ion battery to save charged battery capacity. In other words, the performance directly affects performance on the necessary Li-ion battery size which is the dominant cost factor, or on the maximum driving range which is important KBF (Key Buying Factor) by end-customer.

· Reliability: In order to maximize the module maker's added value such as high reliability and high heat dissipation, the interface specifications of top- / bottom-metallization on semiconductor need to be sensitively adjusted to customers assembly method, like wire bonding, soldering, or even sintering.

· Robustness: Robust design in conversion/control of huge power (e.g. >100kW), knowledge and experience of power semiconductors is essential. We are continuously in the optimization phase by deep collaboration with inverter/module manufacturers.

Renesas Response 1: Low Loss & High Robustness Power device

The design of the Power device is optimized by so complicated and sensitive trade-off parameters to fulfill the market requirement like loss, reliability, robustness, and so on that much experience/know-how is needed. The feature of the Renesas Power device is to realize the highest performance in W/W with keeping enough robustness. This value is admitted by our customers, and as a result, our device is applied by W/W customer’s vehicles. We will introduce the details of our Power device feature next time blog from the designer’s view. You can look forward to it.

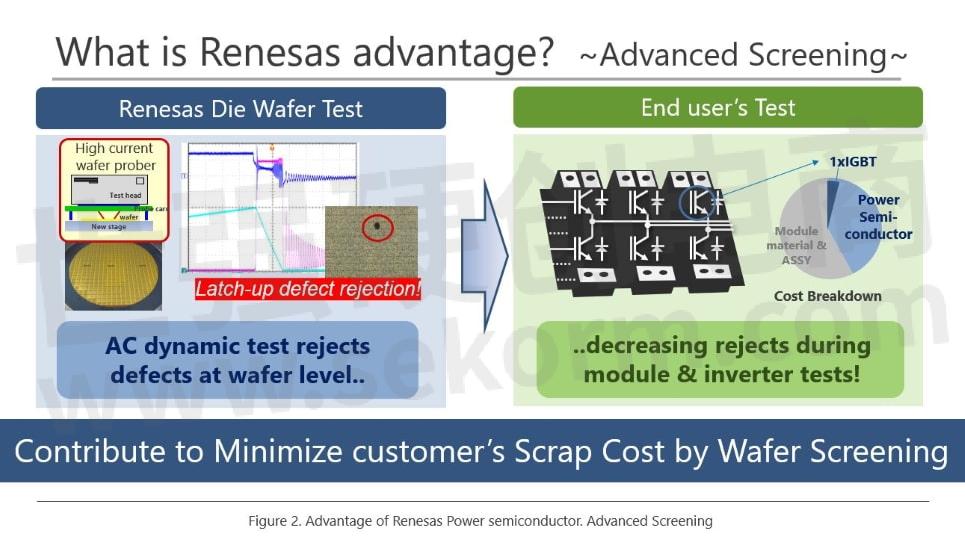

Customer's Expectation 2: Preparing for explosive ramp-up

It is also a remarkable point that OEMs paying attention to keep the supply channel and the stable production for upcoming explosive ramp-up, and accordingly value/expectation on semiconductor is getting higher. From the BCM (Business Continuous Management) point of view, OEMs tend to apply multi-source policy even in semiconductor suppliers. At the same time, stable production support is also being emphasized in the face of ramp-up, such as annual production of 10-thousands to millions of vehicles. For example, enhanced screening in the upstream process or even lot traceability of shipment parts are admitted as added value. Thus, such stable supply capacity and table production support are becoming a new KBF (Key Buying Factor) in addition to conventional factors like prices, performance, and quality, which are generally regarded as mandatory.

Renesas's Response 2: Mass production support by Advanced screening technology

Renesas is the leading screening technology in wafer tests. The screening of potential defects in power devices, which can only be detectable by dynamic stress tests, requires know-how and high technology in wafer tests. On the other hand, if a failure occurred at the customer’s module test, it takes several tens of times of the scrap cost. Therefore it is admitted by the customer as an added value.

- +1 Like

- Add to Favorites

Recommend

- HXY MOSFET Provides A Power Device Solution for LED Backlit LCD TVs

- Hua Xuan Yang Electronics: Domestic Power Device Solutions for PC Power Supplies

- Cmsemicon, Representing the New Power of China, Won the Domestic Power Device Industry Excellence Award

- The Global Power Device Market Will Grow Rapidly

- HXY MOSFET Innovates One Stop Power Device Solution for Neck Massage Devices

- Huaxuan Yang Electronics: UPS Uninterruptible Power Supply Power Device Solution

- HUA XUAN YANG ELECTRONIC Provides A Power Device Solution Tailored for In Car Wireless Mobile Phone Chargers

- Unlocking the Technological Charm of High-Speed Blower Tubes: HXY Power Device Optimization Solutions

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.