SiC FETs are enablers for more efficient motor drives and faster charging

EV uptake is set to increase but ‘range anxiety’ and charge times are still barriers to general acceptance. Wide bandgap semiconductors are enablers for more efficient motor drives and faster charging and new SiC FETs are best performers.

With the latest ‘hyper car’ electric vehicles pushing out nearly 2,000 bhp, things are getting seriously fast on the roads, but range and charge rate are still issue. It’s all well and good getting from charging point A to charging point B at light speed, but if you have to wait there for an hour, it’s not so much fun.

Cutting down on the recharge time would ease a driver’s anxiety if they didn’t feel the need to squeeze the last mile out of the battery to avoid frequent long stops – ultra-rapid chargers at 350kW help but they are few and far between so there is extreme pressure to roll out more and upgrade existing charging stations.

Fast and rapid chargers convert AC line voltages to DC, typically around 400V for most EVs but also 800V for high-performance cars such as the Porsche Taycan. The heart of these chargers is an AC-DC converter that uses IGBT or silicon MOSFET switch technology depending on power level. This can be a difficult choice as IGBTs can only switch relatively slowly because of dynamic losses and therefore force the use of large, costly and lossy magnetic filters. MOSFETs can switch much faster with acceptable dynamic losses and smaller magnetics but high voltage types have high conduction losses. With these losses representing wasted energy and money, and forcing the over-sizing of components to keep temperatures within bounds, better switches are sorely needed.

Wide bandgap (WBG) semiconductors are the answer to many applications needing better efficiency in the shape of SiC or GaN switches and diodes. They are not for the faint-hearted though; layout and driving them correctly is critical, and taming the hypercar-matching speed is necessary to avoid stress and high EMI levels. Practically, converter designs with WBG technology need to be from the ground up to get the best benefit. There is an exception though; a combination part comprising a Si-MOSFET and SiC JFET in a cascode configuration has particular advantages. Called a SiC FET, gate drive is easy, compatible with existing Si-MOSFETs and IGBTs with a wide margin, normalized on-resistance is lower than SiC MOSFETs and GaN and they have inherent high immunity to avalanche effects with over-voltages. Immunity to short circuits is also high with a self-limiting action. Switching losses are generally lower than other WBG devices due to lower device capacitances and all of the general advantages of SiC remain; high critical breakdown voltage, high-temperature operation and high thermal conductivity. Current best-in-class devices from UnitedSiC are achieving under 7 milliohms on-resistance in 650V devices and under 10 milliohms for 1200V types that might be used in 480VAC line systems for the highest power chargers.

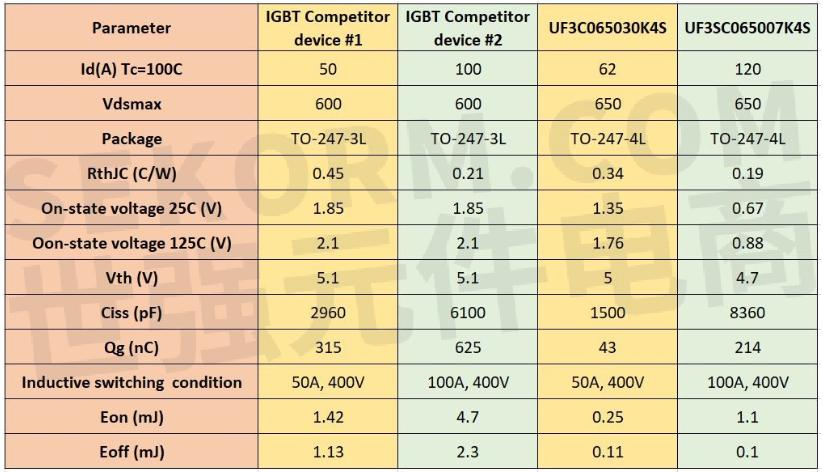

We’ve spoken in generalizations so far, but some figures will illustrate the difference between IGBTs and SiC FETs available in the same package in the 600/650V class, shown in Table 1. Every parameter is better with the SiC devices, meaning fewer losses for a part that can be a near drop-in replacement.

Table 1: 600/650V class IGBTs and SiC FETs compared.

SiC FETS also find a natural home in the necessary power factor correction stage in chargers and also as synchronous rectifiers to replace diodes. This can deliver significant additional power savings, for example, a 350kW rapid charger for a 400V battery has to deliver 875A through a diode bridge arrangement. The rectifiers could be assembled from parallel SiC JBS diodes or SiC FETs configured as synchronous rectifiers. Assuming 100A through each at 50% duty cycle, at 125°C the diodes would drop 2V with a loss of 100W and the SiC FETs would drop 0.9V with just 45W loss, less than half the SiC diode value.

SiC FETs are available in TO-247-4L packages so in many instances can directly change-out IGBTs and Si-MOSFETs, giving the circuit an immediate turbo-boost in efficiency. New designs benefit even more as frequencies can be pushed up without sacrificing efficiency, and associated passive components, particularly magnetics, can be downsized.

This makes Wide bandgap semiconductors such as SiC FETs the ‘Rolls Royce’ of switches.

- +1 Like

- Add to Favorites

Recommend

- UnitedSiC Signs an Authorized Distribution Agreement with Sekorm

- UnitedSiC‘s FET-Jet Calculator Taking The Guesswork out of SiC FET Selection

- The 750V Class of UnitedSiC Gen 4 SiC FETS, Responding to Positive Feedback with More Choice

- UnitedSiC Rediscovers The Perfect Switch with SiC FETs

- UnitedSiC’s Web-based FET-Jet Calculator ——Makes Selection of A SiC FET and SiC Schottky Diode for Your Power Design

- UnitedSiC Announces 6 New SiC FETs, Available in 30/40/80/150mΩ Versions

- Unitedsic Expands Schottky Diode Portfolio To Set New Benchmark in SiC Surge Current Robustness

- UnitedSiC Introduces the Industry‘s First 750V SiC FETs Based on Advanced Gen 4 Technology

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.