Nisshinbo‘s Enhanced Op Amps and LDOs Help Contend with RF Noise in Automotive Applications

Increasing vehicle complexity coupled with a deteriorating RF noise environment is driving the need for components that help automotive engineers' designs comply with electromagnetic-compatibility standards.

Automobiles are rapidly evolving into sophisticated systems whose applications extend far beyond mere transportation. Automakers are positioning their vehicles within a framework called CASE: Connected, Autonomous, Shared, and Electric.

To excel within this framework, vehicles must incorporate an increasing number of electronic control units (ECUs), each of which can become susceptible to electromagnetic noise in the automotive environment while also becoming a potential source of noise in that environment. Each ECU controls functions such as an advanced driver assistance system (ADAS); body control; navigation; tire-pressure monitoring; radar and camera systems; and communications with the Internet, other vehicles, and passengers' cell phones.

ECUs and Noise

Each ECU in turn includes a variety of high-performance integrated components, including operational amplifiers (op amps), low-dropout regulators (LDOs), and voltage trackers. The op amps amplify small signals from sensors distributed throughout a vehicle, while the LDOs and voltage trackers produce accurate, regulated voltages to power the op amps and other components in the ECUs.

With increasing complexity, noise, in the form of electromagnetic interference (EMI), becomes an increasingly important issue. It emanates from the ECUs themselves as well as from high-voltage inverters and electric traction motors and other electrically powered components in the vehicle and the surrounding environment. And as frequencies within this environment expand from hundreds of kilohertz to tens of gigahertz, the challenges related to EMI become increasingly severe, with implications for quality and safety.

To ensure safety while promoting technological advances, organizations such as the International Electrotechnical Commission and related organizations in various jurisdictions promulgate standards for electromagnetic compatibility (EMC) and electromagnetic susceptibility (EMS). The former requires that a component or system not generate excessive interference that could affect other components or systems, and the latter requires that components or systems tolerate exposure to EMI from other sources. Compliance with relevant standards takes time and money. And because compliance testing often occurs in the final stages of vehicle development, extensive rework can be necessary to address compliance test failures.

Choosing Enhanced Op Amps

One approach to achieving EMC/EMS compliance is to choose components such as op amps and LDOs developed specifically to address EMC. Such devices minimize the need for external components to filter EMI, thereby saving board space, component costs, and design time. Nisshinbo Micro Devices, a manufacturer specializing in analog/mixed-signal products, has been focusing on noise immunity for consumer applications since the 2000s and is now applying its knowledge to develop op amps and other components to address noise immunity in automotive and industrial applications.

The conventional method of noise suppression for op amps is to apply a noise filter or other countermeasure circuit in the signal input stage. However, based on a thorough analysis of noise intrusion paths, Nisshinbo has determined that countermeasures are also required at the power-supply inputs, which provide power to the gain and output stages in addition to the input stage (Figure 1). Consequently, the company developed the two-channel NJM2904B and four-channel NJM2902B op amps to provide improved EMC and EMS performance for automotive applications. Both op amps offer a wide input range of 3V to 36V, slew rates of 0.4V/µs (typ.), a gain bandwidth product of 0.9MHz (typ.), and a noise voltage of 30nV/Hz (typ.).

Figure 1. The NJM2904B and NJM2902B op amps include reinforcement on the input and power-supply pins to increase noise immunity.

Nisshinbo designed both op amps specifically to achieve industry-leading immunity over a wide range of frequencies in compliance with the latest standards. Figure 2 shows a comparison of the input-pin and power-supply-pin immunity of the NJM2904B compared with competitive op amps.

Figure 2. The NJM2904B offers improved input-pin and power-supply-pin immunity compared with competitive op amps.

And while capable of handling today's noise levels, these devices can also respond to future deterioration of the automotive noise environment, and they maintain the performance characteristics and design simplicity of a standard automotive op amp. In addition to being suitable for new designs, the op amps can serve as component replacements in existing designs, for which they simplify and help miniaturize printed-circuit board layouts by reducing the number of components required.

LDOs and Voltage Trackers

Nisshinbo also offers LDOs and voltage trackers that can operate stably in noisy automotive environments. The R1525 LDO, for example, operates over an input voltage range of 3.5 to 42V and can deliver an output current of 200mA, while the R1526 operates over the same input voltage range and provides an output current of 300mA.

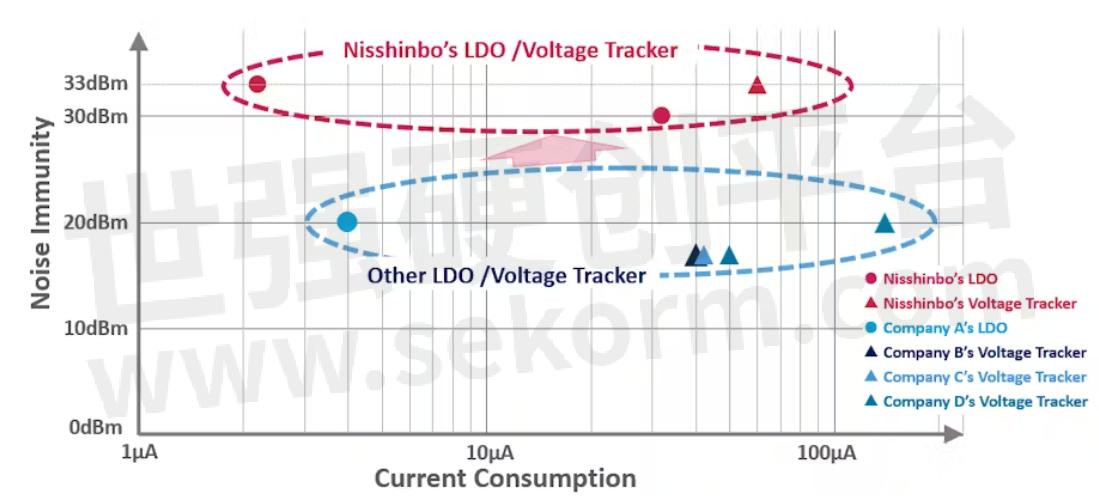

The company also offers the R1540 voltage tracker, which can be used in conjunction with an LDO to power off-board sensors, to disperse heat generated through the linear regulation process, or to serve as a current booster to power a specific circuit block. Like the R1525 and R1526 LDOs, the R1540 also features input voltage in the range of 3.5V to 42V; its output current rating is 70mA. All three devices offer improved noise immunity over a wide range of current consumption compared with competitive devices, as Figure 3 illustrates.

Figure 3. Nisshinbo's LDOs and voltage trackers offer improved noise immunity compared with competitive devices.

Conclusion

As automakers adapt their vehicles to embrace the CASE framework, they are adding ECUs and other electronic and electromechanical components that increase the amount of RF noise in the automotive environment, potentially leading to equipment malfunctions. To help ensure safe and reliable operation in such environments, Nisshinbo offers op amps, LDOs, and voltage trackers that achieve high levels of EMI immunity.

- +1 Like

- Add to Favorites

Recommend

- Nisshinbo Newly Launched NJM2904B Series Operational Amplifier with High Emc Performance and Single Supply

- Nisshinbo Newly Launched NJM2902B Series Operational Amplifier with Supply Voltage of 3V to 36V and Supply Current Typ. Of 0.3mA to Max. 0.425mA

- Nisshinbo Launched Development of First MUSES-Series High-sound-quality Power Management IC

- NISSHINBO‘s 600nA Low Quiescent Current Boost DC/DC Converter for Energy Harvester

- NISSHINBO Launched 0.5A/1A 6MHz PWM/VFM Step-down DC/DC Converter RP539 Series with Synchronous Rectifier

- Visit Nisshinbo at 2024 IEEE MTT-S International Microwave Symposium at June 18 through June 21, 2024

- Started Solution Business Using “Odor Sensing Platform“, Nisshinbo Signed Joint Development Agreement with Ainos and Taiwan Inabata Sangyo

- Now Available: Nisshinbo NL8802,a Low Noise, Dual, High-Quality Sound Audio Operational Amplifier

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.