The Application of IGBT in the Electronic Control System of New Energy Vehicles and Its Heat Dissipation Technology

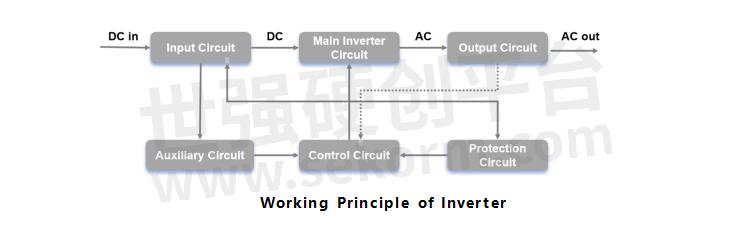

Abstract: The main heating device in the electronic control system of new energy vehicles is the inverter, which converts the direct current of the battery into alternating current that can drive the motor. During this process, the IGBT in the inverter will generate a large amount of heat. To solve the heat dissipation problem of these devices, this article will introduce the working principle of inverters and advanced liquid cooling heat dissipation technology.

1-The Application of IGBT in the Electronic Control System of New Energy Vehicles

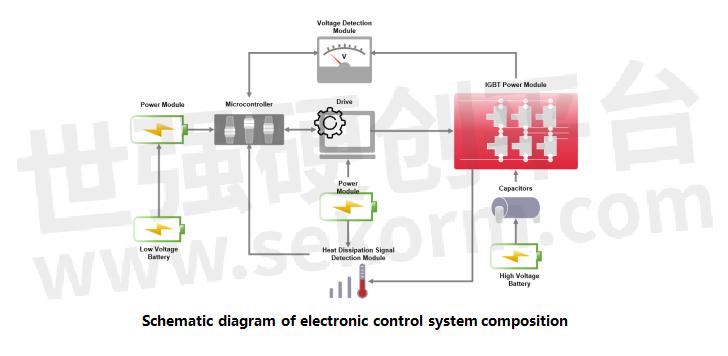

The electronic control system, as the energy conversion unit connecting the battery and the driving motor in new energy vehicles, is the core of motor drive and control. As a device that connects high-voltage batteries and motor power, inverters are responsible for converting direct current energy (batteries, storage batteries) into fixed frequency and voltage or frequency and voltage regulated alternating current (usually 220V, 50Hz sine wave), ensuring the electrical energy conversion of new energy vehicles.

The IGBT power module in the inverter plays a very important role in this process. During the energy conversion process, IBGT will generate a large amount of heat. However, when the temperature of IGBT exceeds 150℃, IGBT cannot function, so air-cooled or water-cooled heat dissipation equipment should be used. The thermal stability of IGBT operation becomes the key to evaluating the performance of electric drive systems.

In addition to the electronic control system, IGBT is also widely used in the onboard air conditioning control system and charging station system of new energy vehicles:

As the core technical component of electric vehicles and charging stations. The IGBT module accounts for nearly 10% of the cost of electric vehicles and about 20% of the cost of charging stations, and its thermal stability becomes the key to evaluating the performance of electric drive systems.

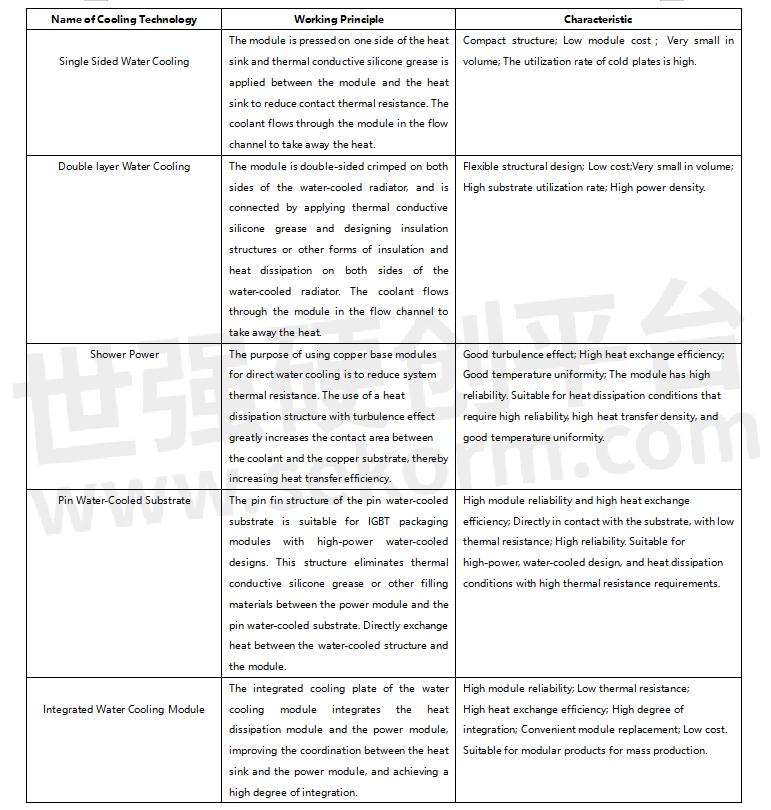

2-IGBT Liquid Cooling Technology

- +1 Like

- Add to Favorites

Recommend

- Vincotech flow E1/E2 Power Module With IGBT M7 for Higher Power Density up to 50A (PIM) and 100A (sixpack)

- Partnership for True Multiple Sourcing: Semikron Danfoss Power Modules with ROHM IGBTs

- Driver technology of the new energy vehicle motor controller IGBT module

- 1200V/600A Half Bridge IGBT Power Module ED600X12T4ALP with Low Saturation Voltage and Low Switching Losses

- Real Chip-level Multi Sourcing - The Multi-sourced Power Modules Featuring IGBT M7 for Motion Control Applications

- 6 Main Fields of Application for WIMA PowerBlock Module

- The Advance of WAYON Domestic IGBT, with higher power cycle life and higher robustness

- How Does Press-fit Technology Elevate IGBT Production?

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.