Top 5 Things You Might Not Know About PTFE Tapes

PTFE (Polytetrafluoroethylene) tapes, also known as high-performance fluoropolymer tapes, are indispensable across industries such as aerospace, automotive, chemical processing, and packaging. While these industrial PTFE tapes are renowned for their superior heat resistance, non-stick properties, and chemical inertness, there's more to these versatile materials than meets the eye.

High-performance PTFE tapes offer a range of benefits that often go unnoticed.

Here are the top five things you might not know about PTFE tapes that showcase their exceptional capabilities:

1. PTFE Tapes Exhibit Extreme Temperature Resilience from Aerospace to Automotive

PTFE tapes excel in high-temperature environments, but they are also able to withstand extremely cold temperatures.

PTFE tapes maintain their properties at temperatures ranging from –94 to 500°F (-70 to 260°C), making them ideal for applications like aerospace thermal shielding and automotive components that are exposed to intense temperature fluctuations. Keep in mind that temperature ranges may vary depending on capabilities of the tape’s adhesive, as tapes in general are limited to the adhesive capabilities regardless of tape type.

DeWAL® PTFE tapes exhibit exceptional temperature versatility. Their ability to perform consistently in both extreme heat and cold sets them apart from other materials, making them a go-to solution for industries facing the most demanding temperature challenges.

2. PTFE Tapes Offer Remarkable Chemical Resistance and Non-Stick Properties

While PTFE materials are famous for their non-stick properties, their chemical resistance is equally impressive.

Chemical-resistant tape solutions like DeWAL PTFE materials maintain durability in harsh chemical environments—whether exposed to acids, solvents, or bases. This makes them suitable for demanding applications in chemical processing, pharmaceutical manufacturing, and other corrosive environments.

From sealing and gasketing to lining applications, DeWAL PTFE materials maintain their integrity where other materials might fail.

3. Clean Removal: The Residue-Free Advantage of PTFE Tapes

One of the significant benefits of DeWAL PTFE tapes is their ability to be removed cleanly without leaving any residue.

These PTFE industrial tapes excel in process aid applications, designed for repeated use in extreme conditions and clean removal afterward. This feature is especially useful in mold release applications, industrial processes, sealing operations, and other scenarios where adhesive residue could compromise performance and product quality. The residue-free nature of PTFE tapes ensures consistent results and reduces maintenance time and costs.

4. PTFE Tapes Comply with Rigorous Industry Standards

PTFE tapes don’t just perform well; they also meet stringent industry standards.

DeWAL PTFE tapes meet various UL and MIL specifications, ensuring reliable performance in regulated industries such as aerospace, automotive, and electronics.

By meeting stringent industry standards, DeWAL PTFE tapes can be utilized in applications where safety, quality, and compliance are critical—like electrical insulation, composite manufacturing, and sealing applications.

5. Versatility in Action

Whether you need tapes for aerospace, automotive, or chemical processing, there’s a DeWAL PTFE tape specially designed for practically any requirement.

Looking for a New PTFE Tape Supplier?

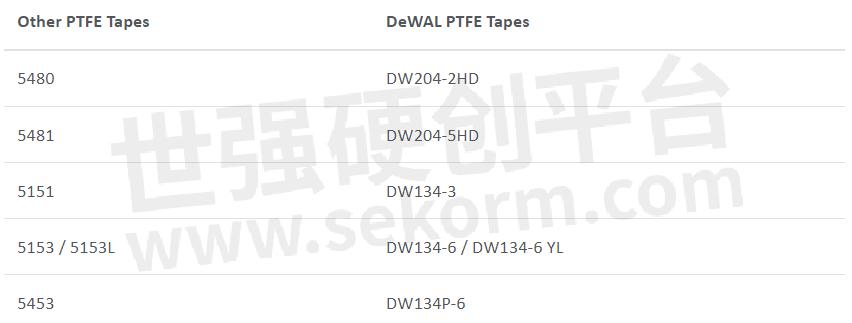

If you've relied on other PTFE tape suppliers in the past and are having trouble sourcing PTFE tapes, ROGERS has you covered with a reliable DeWAL replacement. Use this cross-reference guide to find the DeWAL equivalent to your product:

Key Takeaways

PTFE tapes are more than just high-temperature materials; they are versatile, durable, and engineered to meet stringent industry standards. Whether you’re looking for a reliable supplier for PTFE tapes or just exploring new materials for demanding applications, DeWAL PTFE tapes offer an exceptional combination of performance and reliability.

Ready to explore the reliability of DeWAL PTFE Tapes for yourself?

- +1 Like

- Add to Favorites

Recommend

- Rogers Announces Acquisition of Silicone Engineering

- Sekorm Became an Authorized Distributor of Rogers

- Rogers Announces Termination of Merger Agreement with DuPont

- Rogers Corporation Introduces New Water-Resistant Flexible Heater Substrate

- Rogers Corporation Announces Further Actions to Streamline Operations and Drive Margin Improvement

- Rogers Corporation Announces Intention to Consolidate Manufacturing Facilities for RO3000® and RO4000® Product Lines

- Rogers Expands Capabilities and Services with New Application Laboratory

- Rogers‘ Micro Channel Coolers (MCC) in High Performance Computing (HPC) Applications

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.