What is D-sub Connector Contacts ?

1.What is the size, current and voltage rating of this connector?

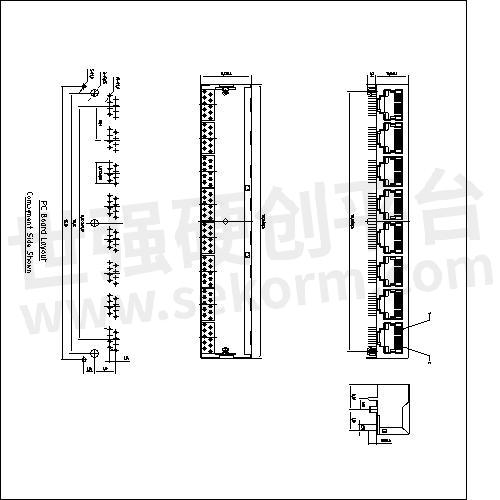

D-sub Connector Contacts are available in various sizes, each with different current and voltage ratings. The most common sizes are D-sub 9, D-sub 15, D-sub 25, and D-sub 37, which refer to the number of pins or contacts in the connector.

For the D-sub 9 connector, which has 9 pins, the current rating is typically around 5 amps per pin. This means that each pin can handle up to 5 amps of current. The voltage rating for the D-sub 9 connector is typically around 250 volts.

The D-sub 15 connector, with 15 pins, usually has a current rating of around 3 amps per pin. The voltage rating for this connector is typically around 250 volts as well.

The D-sub 25 connector, with 25 pins, typically has a current rating of around 1 amp per pin. The voltage rating for this connector is also around 250 volts.

For the D-sub 37 connector, with 37 pins, the current rating is usually around 1 amp per pin, similar to the D-sub 25 connector. The voltage rating is also around 250 volts.

It is important to note that these ratings can vary depending on the specific manufacturer and the intended application of the connector. It is always recommended to refer to the datasheet or specifications provided by the manufacturer for the exact current and voltage ratings of a specific D-sub connector.

D-sub Connector Contacts are commonly used in applications where moderate current and voltage levels are required, such as in computer peripherals, communication devices, and industrial equipment. They provide a reliable and secure interface for transmitting signals and power between different components, ensuring efficient and safe operation.

2. Are there different socket types to choose from?

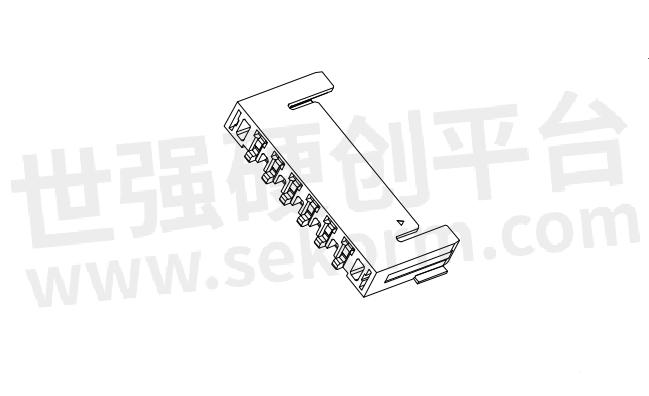

Yes, there are different socket types available for D-sub Connector Contacts. The socket types refer to the shape and configuration of the female contacts in the connector. The most common socket types for D-sub connectors include standard sockets, high-density sockets, and mixed-layout sockets.

Standard sockets, also known as regular density sockets, are the traditional socket type for D-sub connectors. They have a standard spacing between the contacts, which allows for easy mating with standard male pins. Standard sockets are commonly used in a wide range of applications, including computers, communication devices, and industrial equipment.

High-density sockets are designed to fit more contacts within the same size connector. These sockets have a smaller spacing between the contacts, allowing for a higher number of contacts to be accommodated in a smaller connector size. High-density sockets are typically used in applications where space is limited, such as compact electronic devices or high-density circuit boards.

Mixed-layout sockets combine Standard Density and high-density contacts within the same connector. These sockets have both standard spacing and smaller spacing sections, allowing for a combination of different pin sizes and contact densities within a single connector. Mixed-layout sockets are often used in applications where a combination of standard and high-density connections is required, providing flexibility and versatility in the design.

In addition to the different socket types, D-sub Connector Contacts also come with various termination options. The termination refers to the method of connecting the contacts to the circuit board or cable. Common termination options include solder cup, straight PCB, right-angle PCB, crimp, and wire-wrap. The choice of termination option depends on the specific application requirements and the type of connection needed.

It is important to note that the selection of socket types and termination options may vary depending on the manufacturer and the specific series or model of D-sub Connector Contacts. It is recommended to refer to the manufacturer's datasheet or specifications to determine the available socket types and termination options for a particular D-sub connector.

In conclusion, D-sub Connector Contacts offer a range of socket types and termination options to suit different application requirements. Whether it is a standard socket, high-density socket, or mixed-layout socket, there are choices available to accommodate various pin configurations and contact densities. The selection of the socket type and termination option depends on factors such as space constraints, pin layout, and specific application needs.

3.Main purposes and application areas

D-sub Connector Contacts have a wide range of purposes and are used in various application areas. These contacts are primarily designed to establish secure electrical connections and transmit signals between different components in electronic devices and equipment. Some of the main purposes and application areas of D-sub Connector Contacts are as follows:

Computer and IT Equipment: D-sub Connector Contacts are commonly used in computer systems and IT equipment. They provide a reliable interface for connecting peripherals such as mice, keyboards, monitors, and printers to the computer. These contacts enable the transmission of signals and data between the computer and its peripherals, ensuring seamless communication and functionality.

Communication Devices: D-sub Connector Contacts are widely utilized in communication devices such as routers, modems, and networking equipment. They enable the connection of various components in these devices, allowing for the transmission of signals and data between different network interfaces. These contacts ensure reliable and efficient communication in networking applications.

Industrial Automation: D-sub Connector Contacts find extensive usage in industrial automation systems. They are commonly employed in control panels, PLCs (Programmable Logic Controllers), and other automation equipment. These contacts provide a secure and stable connection for transferring control signals and data between different components in industrial automation systems. They are designed to withstand harsh industrial environments and ensure reliable operation.

Medical Equipment: D-sub Connector Contacts are utilized in medical equipment, including diagnostic devices, imaging systems, and patient monitoring systems. They enable the connection of various medical components, allowing for the transmission of signals and data within these systems. The contacts are designed to meet specific medical standards and provide reliable performance in medical applications.

Aerospace and Defense: D-sub Connector Contacts are commonly used in aerospace and defense applications. They are employed in avionics systems, military communication systems, radar systems, and other aerospace and defense equipment. These contacts offer a secure and robust connection for transmitting signals and data in demanding environments, ensuring the reliable operation of critical systems.

Test and Measurement Equipment: D-sub Connector Contacts are widely utilized in test and measurement equipment. They enable the connection of probes, sensors, and other measuring devices to the equipment, allowing for the accurate measurement and analysis of signals. These contacts provide a reliable interface for transferring signals and data between the equipment and the measuring devices.

In conclusion, D-sub Connector Contacts are versatile components used in a wide range of applications. Their main purposes include establishing electrical connections, transmitting signals and data, and enabling the seamless operation of electronic devices and equipment. Whether it is in computer systems, communication devices, industrial automation, medical equipment, aerospace and defense, or test and measurement equipment, D-sub Connector Contacts play a crucial role in ensuring reliable and efficient connectivity.

4. How durable and reliable is it?

D-sub Connector Contacts are known for their durability and reliability. These contacts are designed to withstand harsh conditions and provide a secure and stable connection.

One of the factors that contribute to the durability of D-sub Connector Contacts is their construction. These contacts are typically made of high-quality materials such as brass or phosphor bronze, which offer excellent conductivity and corrosion resistance. The contacts are often gold or silver plated to further enhance their durability and ensure reliable performance over time. The plating helps to prevent oxidation, which can degrade the electrical conductivity of the contacts.

In addition to their robust construction, D-sub Connector Contacts are designed to withstand mechanical stress and vibrations. They are engineered to provide a tight and secure connection, minimizing the risk of intermittent or unstable connections. The contacts are often designed with locking mechanisms or retention features to ensure that they stay securely mated, even in high-vibration environments.

Furthermore, D-sub Connector Contacts undergo rigorous testing to ensure their reliability. They are subjected to various tests, including electrical performance testing, mechanical stress testing, and temperature cycling testing. These tests are conducted to ensure that the contacts can withstand different environmental conditions and maintain their performance over a long period of time.

The reliability of D-sub Connector Contacts is also demonstrated through their widespread use in various industries and applications. They have a proven track record of providing stable and consistent electrical connections in critical applications such as aerospace, defense, and industrial automation. Many manufacturers of D-sub Connector Contacts provide extensive warranty and support to assure customers of their reliability.

It is important to note that the durability and reliability of D-sub Connector Contacts can also depend on factors such as proper installation, maintenance, and usage. Following recommended installation procedures and ensuring proper mating and unmating of the connectors can contribute to their long-term reliability.

In conclusion, D-sub Connector Contacts are highly durable and reliable components. Their robust construction, corrosion resistance, mechanical strength, and extensive testing make them suitable for demanding applications. Whether it is in harsh industrial environments or critical aerospace systems, D-sub Connector Contacts have proven to be dependable and provide secure electrical connections.

5. How does it work?

D-sub Connector Contacts are essential components that facilitate the transmission of signals and power between different electronic devices and equipment. These contacts work by establishing electrical connections between the male and female connectors.

The male connector, also known as the plug, consists of a series of metal pins that correspond to the female contacts in the female connector, commonly referred to as the socket. The female contacts are housed in a dielectric insulator, which provides electrical isolation and mechanical support.

The male pins of the plug are designed to fit into the corresponding female contacts of the socket. When the plug is inserted into the socket, the pins make contact with the female contacts, creating a secure and stable connection. The male pins are typically made of brass or phosphor bronze, which provide excellent conductivity.

The female contacts in the socket are constructed with a tubular shape, allowing the male pins to slide into them. These contacts are often made of the same high-quality materials as the male pins and are gold or silver plated to enhance their conductivity and resistance to corrosion. The plating also helps ensure reliable and consistent electrical connections.

Inside the female contacts, there are spring-loaded mechanisms, such as cantilever beams or leaf springs, that exert a constant pressure on the male pins. This pressure helps to maintain a tight and reliable connection, even in the presence of vibrations or mechanical stresses. The spring-loaded contacts also compensate for any slight variations in the dimensions of the male pins, ensuring a proper and consistent mating.

D-sub Connector Contacts can transmit various types of signals, including analog, digital, and power signals. The number of contacts and their arrangement in the connector determine the specific functionalities and capabilities of the connection. Common D-sub Connector configurations include 9, 15, 25, and 37 contact positions, but there are also higher-density versions available.

The electrical signals and power are transmitted through the contact points, which are the areas of contact between the male pins and female contacts. These contact points provide low resistance paths for the signals, allowing for efficient transmission without significant signal loss or interference.

To ensure proper operation and optimal performance, it is important to follow the recommended installation procedures when connecting D-sub Connector Contacts. This includes aligning the pins with the corresponding contacts and applying proper insertion and extraction forces. It is also advisable to periodically inspect and clean the contacts to remove any debris or contamination that may affect their functionality.

In conclusion, D-sub Connector Contacts work by establishing electrical connections between male and female connectors. Through the mechanical mating of male pins and female contacts, these contacts facilitate the transmission of signals and power in various electronic devices and equipment. Their design, construction, and proper installation contribute to their reliable performance and efficient functionality.

- +1 Like

- Add to Favorites

Recommend

- ILME D-SUB Series Connectors for Data-Signal Connection

- What is Solder Cup Power D-Sub Connector?

- Problems Needing Attention When Selecting High Current D-sub Connector

- What is IDC D-Sub Connectors ?

- What is Vertical Mount Power D-SUB Connectors?

- Littelfuse Introduces MDMA-MDMB Micro-D Connector Series with Removable Crimp Contacts for Aerospace Industry

- Smiths Interconnect’s High-speed D-sub Connectors and Harnesses Helped Ensure Astronaut Safety

- Antenk Electronics Appeared in Guangzhou International Intelligent Manufacturing Exhibition with A Series of High-performance Connector Application Solutions

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.