What is Vertical Mount Power D-SUB Connectors?

1.What is the size, current and voltage rating of this connector?

The Vertical Mount Power D-SUB Connectors are widely used in various electronic applications due to their reliable performance and versatility. These connectors have a compact and durable design, making them ideal for high-density applications where space is limited.

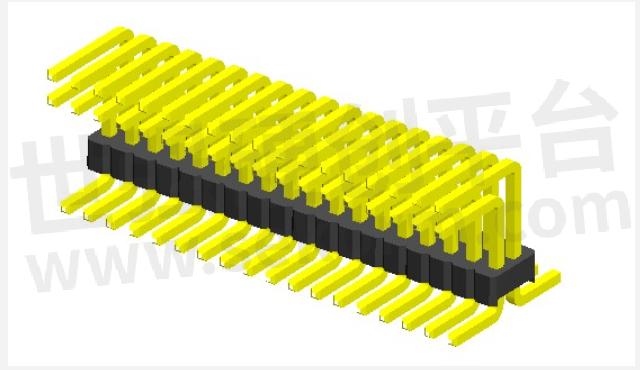

The size of the Vertical Mount Power D-SUB Connectors is typically in accordance with industry standards. They are available in various sizes, including 9-pin, 15-pin, 25-pin, 37-pin, and 50-pin configurations, to meet different requirements. The connectors are designed to be vertically mounted on printed circuit boards (PCBs), ensuring secure and stable connections.

In terms of current rating, the Vertical Mount Power D-SUB Connectors can handle a wide range of current levels, depending on the specific model and design. The current rating typically ranges from 5A to 20A, allowing for a reliable and efficient power transmission.

Regarding voltage rating, the Vertical Mount Power D-SUB Connectors can accommodate voltages up to a certain level. The voltage rating varies depending on the specific connector model and application. However, these connectors are generally designed to handle voltages up to 250V, providing a safe and efficient power transfer.

In addition to their size, current rating, and voltage rating, the Vertical Mount Power D-SUB Connectors also offer several key features and benefits. These connectors feature a robust construction with high-quality materials, ensuring durability and longevity even in harsh environments. They have a secure locking mechanism that provides a secure and stable connection, minimizing the risk of accidental disconnection.

The Vertical Mount Power D-SUB Connectors are also equipped with gold-plated contacts, which offer excellent conductivity and corrosion resistance. This ensures a reliable and low-resistance connection, minimizing power loss and signal distortion. The connectors also have a high-density design, allowing for the efficient use of space on PCBs.

Overall, the Vertical Mount Power D-SUB Connectors are a reliable choice for various power transmission applications. Their compact size, high current rating, and voltage rating make them suitable for a wide range of electronic devices. Whether used in industrial machinery, telecommunications equipment, or computer systems, these connectors provide a secure and efficient power connection.

2. Are there different socket types to choose from?

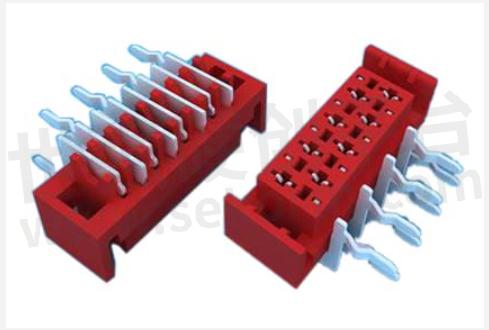

The Vertical Mount Power D-SUB Connectors come in a variety of socket types, providing users with options to meet their specific requirements. These socket types include standard sockets, high-density sockets, and mixed layout sockets.

Standard sockets are the most common type of Vertical Mount Power D-SUB Connectors. They have a standard pin layout and are widely used in a variety of applications. These connectors are available in different pin counts, ranging from 9 pins to 50 pins, allowing for versatile connectivity solutions.

High-density sockets, as the name suggests, offer a higher pin density compared to standard sockets. They are designed to accommodate more pins in a smaller footprint, making them ideal for applications where space is limited. High-density sockets are commonly used in computer systems, telecommunications equipment, and other high-density electronic devices.

Mixed layout sockets are a combination of standard and high-density pin layouts. They feature a combination of standard pins and high-density pins in the same connector. This allows for flexibility in connectivity options, as it allows for both standard and high-density connections in a single connector. Mixed layout sockets are often used in applications where a combination of standard and high-density connections is required.

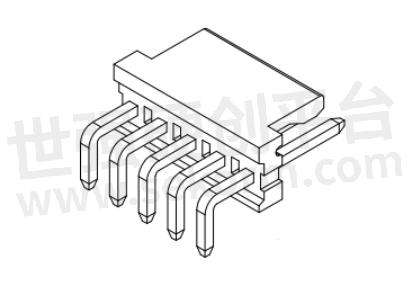

In addition to the different socket types, the Vertical Mount Power D-SUB Connectors also offer options for different termination methods. These include solder cup, straight PCB mount, and right-angle PCB mount terminations. The choice of termination method depends on the specific application and the desired mounting orientation.

Overall, the availability of different socket types and termination methods in the Vertical Mount Power D-SUB Connectors provides users with a wide range of options to choose from. This ensures that they can find the right connector for their specific application needs, whether it is a standard socket for general connectivity, a high-density socket for space-constrained applications, or a mixed layout socket for a combination of standard and high-density connections.

3. Main purposes and application areas

Vertical Mount Power D-SUB Connectors are widely used in various electronic applications due to their versatility and reliable performance. They are designed to provide a secure and efficient power connection for different devices and systems.

One of the main purposes of Vertical Mount Power D-SUB Connectors is to facilitate power transmission in industrial machinery. These connectors are commonly used in manufacturing equipment, automation systems, and control panels. They offer a reliable and efficient power transfer, ensuring smooth operation and optimal performance of industrial machinery.

Another important application area for Vertical Mount Power D-SUB Connectors is in telecommunication equipment. These connectors are used in routers, switches, modems, and other networking devices to establish a power connection. They provide a secure and stable power supply, enabling reliable data transmission and communication in telecommunication systems.

Vertical Mount Power D-SUB Connectors are also widely used in computer systems. They are commonly found in desktop computers, servers, and peripherals such as monitors and printers. These connectors facilitate the power supply to different components of computer systems, ensuring their proper functioning and performance.

In addition to industrial machinery, telecommunication equipment, and computer systems, Vertical Mount Power D-SUB Connectors find applications in a wide range of other electronic devices and systems. They are used in medical equipment, automotive electronics, aerospace systems, and many other areas.

In the medical field, these connectors are used in devices such as patient monitors, diagnostic equipment, and laboratory instruments. They provide a reliable power connection, ensuring accurate readings and precise measurements in medical devices.

In the automotive industry, Vertical Mount Power D-SUB Connectors are used in various electronic components and systems, including in-car entertainment systems, navigation systems, and engine control units. These connectors play a crucial role in providing power supply and ensuring the smooth operation of automotive electronics.

In aerospace systems, Vertical Mount Power D-SUB Connectors are used in avionics equipment, satellite systems, and communication systems. They are designed to withstand harsh environmental conditions and provide a secure power connection, ensuring the safety and reliability of aerospace systems.

Overall, Vertical Mount Power D-SUB Connectors are widely used in various industries and applications where a reliable power connection is required. Their versatility, compact size, and high current and voltage ratings make them a preferred choice for many electronic devices and systems. Whether in industrial machinery, telecommunication equipment, computer systems, or other electronic devices, these connectors provide a secure and efficient power transfer for optimal performance.

4. How durable and reliable is it?

Vertical Mount Power D-SUB Connectors are known for their durability and reliability, making them a popular choice for various electronic applications. These connectors are designed to withstand demanding conditions and provide a long-lasting and stable power connection.

One of the key factors contributing to the durability and reliability of Vertical Mount Power D-SUB Connectors is their construction. These connectors are typically made with high-quality materials such as metal shells and robust insulators. The metal shells provide excellent protection against physical impact and ensure the connectors can withstand harsh environments. The insulators are designed to offer insulation and prevent electrical leakage, ensuring a secure and reliable power transfer.

Furthermore, Vertical Mount Power D-SUB Connectors are often equipped with gold-plated contacts. Gold plating offers several benefits, including excellent conductivity and corrosion resistance. The gold plating ensures a low-resistance connection, minimizing power loss and signal distortion. It also helps to prevent oxidation and ensures a reliable and long-lasting electrical connection.

In addition to their construction, Vertical Mount Power D-SUB Connectors undergo rigorous testing and quality control processes to ensure their performance and reliability. These connectors are tested for factors such as electrical performance, temperature resistance, and mechanical strength. By meeting or exceeding industry standards, these connectors provide a high level of reliability in various applications.

Vertical Mount Power D-SUB Connectors are also designed with a secure locking mechanism. This mechanism ensures a stable and secure connection, minimizing the risk of accidental disconnection. The connectors are designed to withstand vibrations and shocks, further enhancing their durability and reliability.

Moreover, these connectors are designed to have a long operational life. They can endure multiple insertions and removals without compromising their performance. This makes them suitable for applications that require frequent plugging and unplugging, such as test equipment or portable devices.

Overall, Vertical Mount Power D-SUB Connectors are known for their durability and reliability. Their robust construction, gold-plated contacts, secure locking mechanism, and long operational life ensure a stable and efficient power connection in various electronic applications. Whether used in industrial machinery, telecommunication equipment, or computers, these connectors provide a reliable solution for power transmission.

5. How does it work?

Vertical Mount Power D-SUB Connectors are a type of electrical connector that is widely used in various applications for power transmission. These connectors are designed to provide a secure and efficient power connection between devices and systems.

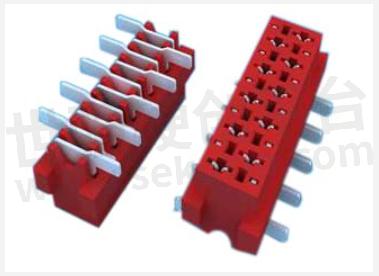

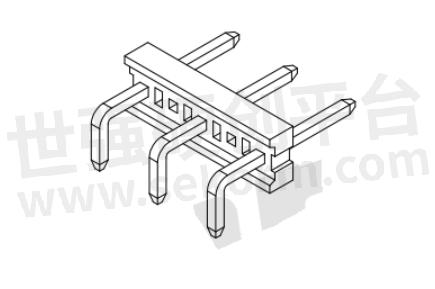

The working principle of Vertical Mount Power D-SUB Connectors involves the interaction of several components within the connector. The main components include the metal shell, insulator, contacts, and locking mechanism.

The metal shell serves as the outer protective casing of the connector. It provides physical strength and durability, protecting the internal components from damage. The metal shell also acts as a shield, preventing electromagnetic interference and ensuring signal integrity.

Inside the metal shell, there is an insulator that separates the contacts and provides electrical insulation. The insulator is typically made of high-quality materials such as plastic or ceramic. It prevents electrical leakage and ensures a secure connection between the contacts.

The contacts are the key components of the connector that facilitate the transmission of power. They are typically made of metal, such as copper or brass, and are designed to provide a low-resistance path for the flow of electrical current. The contacts are arranged in a specific pattern, known as the pin layout, which determines the type and number of connections the connector can provide.

To establish a power connection, the Vertical Mount Power D-SUB Connector is inserted into a corresponding socket or receptacle. The contacts on the connector align with the contacts on the socket, creating an electrical connection. The contacts are designed to provide a tight and secure fit, minimizing the risk of accidental disconnection.

Once the connector is inserted into the socket, the locking mechanism is engaged to ensure a secure connection. The locking mechanism varies depending on the specific design of the connector but typically involves a latch or screw mechanism. This prevents the connector from being accidentally unplugged, ensuring a stable and uninterrupted power supply.

Vertical Mount Power D-SUB Connectors are designed to handle a wide range of power requirements, from low voltage to high current applications. They are capable of providing reliable power transmission while minimizing power loss and signal distortion.

In conclusion, Vertical Mount Power D-SUB Connectors work by establishing a secure and efficient power connection between electronic devices and systems. Through their robust construction, precise pin layout, and reliable locking mechanism, these connectors ensure a stable and reliable power supply, making them suitable for various applications in industries such as industrial machinery, telecommunications, and computers.

- +1 Like

- Add to Favorites

Recommend

- ILME D-SUB Series Connectors for Data-Signal Connection

- UU Winding Common Mode Choke Commonly Used in Switching Power Supply: Xiangru Electronic XRUU9.8-10mH-V, Vertical Plug-in Design, Low Loss

- What is Coaxial Power D-Sub Solder Cup?

- Smiths Interconnect’s High-speed D-sub Connectors and Harnesses Helped Ensure Astronaut Safety

- What is IDC D-Sub Connectors ?

- What is Solder Cup Power D-Sub Connector?

- China’s Best DC-DC Converters manufacturers, Get Your Power Where You Need It!

- Antenk Electronics Appeared in Guangzhou International Intelligent Manufacturing Exhibition with A Series of High-performance Connector Application Solutions

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.