Risks of Channel Contamination and Cleaning Control Techniques in the Manufacturing Process of Liquid-Cooled Plates

As

the power density and heat generation of various electronic and power

products continue to rise, heat dissipation faces increasingly severe

challenges. Liquid cooling solutions are gradually becoming the

mainstream option due to their efficient heat dissipation, low energy

consumption, low noise, and high reliability.

Liquid cooling systems work by attaching cooling plates to battery packs (or other heat sources) and using circulating coolant to carry away the heat generated during operation. This heat is then transferred through one or more cooling circuit heat exchangers, ultimately dissipating the thermal energy of the energy storage system into the external environment.

Flanged style battery tray in BESS

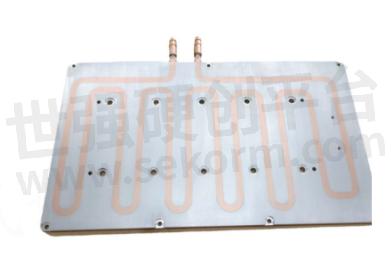

Cold plate in Solar inverter

As a core component of liquid cooling solutions, the liquid-cooled plate is an efficient heat dissipation component. Its primary function is to remove heat generated by the battery (or other heat sources) through the circulation of coolant, keeping the equipment operating within a safe temperature range. If the channels of the liquid-cooled plate are not clean, it can affect the uniformity of coolant flow. Larger foreign particles can block or impede coolant flow, leading to ineffective heat transfer and consequently impacting the heat dissipation efficiency and overall performance of electronic devices.

Moreover, if impurities remain in the channels, they may damage the oxidation protective film on the metal surfaces, causing corrosion or erosion of the liquid-cooled plate. Additionally, impurities in the channels can lead to poor component contact, potentially causing seal aging or damage, which increases the risk of leakage and affects the long-term stable operation of the system.

1-Cleanliness Requirements for Liquid-Cooled Plate Channels

Current energy storage liquid cooling solutions generally require that no foreign objects, aluminum chips, oil, or liquids are present in the channels. In some cases, specific quality requirements regarding the size of hard and soft particles may be defined.

2-High-Risk Contamination Phases in Liquid-Cooled Plate Manufacturing

During the processing and manufacturing of cold plates, the internal channels and cooling interfaces are particularly vulnerable. The manufacturing processes, including cutting and channel removal, can easily introduce foreign objects such as oil, cutting coolant, and machining chips into the channels. The machining operations occur at the channel entrances, making protection difficult, and once chips enter, they are hard to remove.

(Processing of Liquid-Cooled Plate Components: Channel Removal and Deburring)

After the processing of the cold plate channel, components such as plugs and water nozzles are welded to form closed channels. The channel structure is typically non-linear, which creates blind spots for flushing. After welding, the machining process requires a large amount of cutting coolant for the tools and workpieces, generating significant metal chips. This step is particularly prone to contamination from coolant, chips, and other pollutants, which are difficult to completely remove once they enter.

3-Cleaning and Protection of Liquid-Cooled Plate Channels

To ensure the reliability and performance of liquid-cooled plate components, strict cleaning operations are typically performed. High-pressure water jets are used to flush the internal channels of the liquid-cooled plate to remove any residues, particles, or other impurities. After flushing, the liquid-cooled plate components need to be dried to ensure no moisture remains in the channels.

(Processing of Liquid-Cooled Plate Components:flushing and degreasing)

If the cold plates and other liquid-cooled components are not adequately protected during manufacturing, they are susceptible to contamination from metal chips, oil, cutting coolant, etc., especially during the machining process. The handling process of the cold plates also easily allows foreign objects to enter. Generally, protective measures at the channel entrances are considered in advance, such as dust covers and rubber sleeves for water nozzles.

Thus, cleaning the internal channels of cold plates becomes a necessary measure to eliminate channel contamination and enhance channel cleanliness. In production practice, comprehensive preventive controls should be implemented throughout the process. Based on this, specific contamination control measures should be proposed for particular components and processes to effectively manage the contamination inside the cold plate channels.

- +1 Like

- Add to Favorites

Recommend

- The Liquid Cooling Plate Passed the Air Tightness Test, So Why does Leakage Still Occur?

- Aavid‘s Liquid Cooling Systems: Modular or fully customized liquid cooling optimized for improved heat dissipation in condensed volumes

- The BOYD Specialty Vehicle Battery Liquid Cold Plate Increases Thermal Performance While Decreasing the Weight of the Battery Pack by over 40%

- Trend towards Liquid Cooling Systems

- Liquid to Liquid Ambient Cooling Systems for Semiconductor Tools

- Boyd Corporation Acquires Lytron, Expands Liquid Cooling Offerings

- LS03 Series Standard Liquid Level Sensor for Horizontally Mounting, Feature Magnetic Floats which Activate Reed Switches When the Liquid Level Rises or Falls

- IMS. LLS Series Infrared Photoelectric Liquid Level Switch Suitable for Transparent or Non-Transparent Liquids Measurement

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.