Innovative Product Solution for Semiconductor Customers: WACKER Develops New Specialty Silane for High-Performance Microchips

WACKER is expanding its specialty portfolio for the semiconductor industry with the development of a new precursor silane for the fabrication of highly integrated memory chips and microprocessors. Such computer chips play an important role, for instance, in highly complex calculations that are typically required in artificial intelligence or cloud computing. WACKER’s new silane is used for chemical vapor deposition in semiconductor manufacturing. It reacts with the surface of the wafer and creates an ultrathin insulation layer with a low dielectric constant. This shields electromagnetic fields from the tightly arranged interconnects and circuits and ensures the reliable and trouble-free functioning of highly integrated microchips. The new silane shows once again how the WACKER Group focuses on customer-specific solutions with high added value.

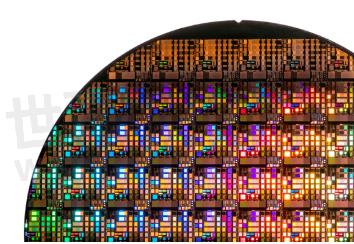

WACKER has developed a new precursor for the manufacture of highly integrated memory chips and microprocessors. The new specialty chemical ensures the reliable and trouble-free functioning of highly integrated microchips for cloud computing and AI applications. (photo: WACKER)

Modern semiconductor chips contain billions of transistors squeezed into the tightest of spaces. Increasing miniaturization has brought with it a rise in the number of transistors and boosted semiconductor performance, but also presents several technical challenges. One problem, for example, is the interactions between the interconnects and the transistors. As a consequence of the growing number of circuits and ever-higher switching frequencies, electromagnetic fields are limiting the performance of the latest generation of microchips.

A new product from WACKER now offers a practical solution. The product, a Specialty Silane consisting of silicon, carbon and chlorine, is an important layer-forming precursor in the production process of semiconductors. It reacts with the surface of the heated hyperpure silicon wafer to create an insulating layer with a low dielectric constant. This reduces electromagnetic interference on the charges moving at high frequency in the interconnects.

“Thanks to intensive research work, our chemists have succeeded in developing a silane that improves the performance of microchips significantly,” says Thomas Koini, head of WACKER’s SILICONES division. “The product facilitates the development of computer chips with highly integrated and highly complex structures. These types of chips are increasingly required for applications that have to handle intensive computational tasks, such as artificial intelligence, autonomous driving, and cloud computing.”

- +1 Like

- Add to Favorites

Recommend

- WACKER Expands Specialty Silicone Production in China

- The BOYD Specialty Vehicle Battery Liquid Cold Plate Increases Thermal Performance While Decreasing the Weight of the Battery Pack by over 40%

- Coherent Releases New Specialty Optical Fiber for Lidar and Quantum Computing Applications

- Microchips Are Manufactured Using Polysilicon and Specialty Chemicals Made by WACKER

- Discover the Uniqueness of ONPOW‘s Special Push Button Switches

- Shenzhen Hottech Won The Recognition of Specialized, Special and Innovative SMES in 2022

- How to Custom Your Special-shape Battery?

- WACKER Engineering Silicones Tech Center in Burghausen

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.