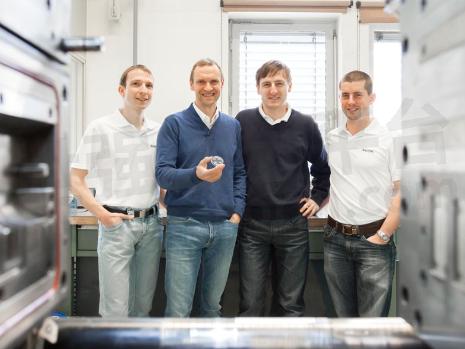

WACKER Engineering Silicones Tech Center in Burghausen

“We want to provide the best technical support for silicones,” says Klaus Wenzeis (second from left) when asked what makes the Burghausen Tech Center special. A look behind the scenes of the Engineering Silicones Tech Center shows that a lot of dedication lies behind these few words, with everyone having a hand in research, development, consulting, coaching and testing. Their work revolves around a versatile material, a seasoned team, and technology that works.

Enhancing the Properties of Existing Materials

The Engineering Silicones Tech Center opened in March 2000, and Klaus Wenzeis has been there from the beginning. While he helped establish it and now leads it, he is not the only one devoting 14 years of experience and expertise to the Tech Center. He and the four other members of his team have been working together the entire time – and their enduring collaboration has benefited WACKER customers. The primary objective of the veteran team is to optimize existing customer formulations and processes in order to make more efficient products and devise cost-effective processes. Another priority is to develop new applications and corresponding prototyping/mold trial processes, either upon the request of a customer or on the basis of work carried out by the Consortium (the heart of research and development at WACKER). The service portfolio is rounded out by project support, consultation and in-depth dialogue with contacts – focal points that create added value for both sides.

Feel free to make use of the comprehensive services that our Technical Center has to offer, and benefit from more efficient products and processes.

Facts & Figures

Over the past three years, the Engineering Silicones Tech Center

Addressed roughly 100 issues externally, i.e. at customer sites,

For which the team traveled to all of the world’s continents,

Used approximately 6,000 kg of material for experiments,

Found solutions within 1 - 10 days,

And developed completely new applications within periods ranging from 10 weeks to 3 years.

Troubleshooting in Two Days

Klaus Wenzeis has just returned from Seoul. A process engineer, Wenzeis has managed the Engineering Silicones Tech Center in Burghausen for 14 years. For this most recent trip, he flew 8,547 kilometers and had three days to resolve a thorny issue on site. That happens sometimes – whenever a customer has a unique problem: a problem that the specialists at WACKER’s global technical centers cannot solve and that the experts at the Engineering Silicones Tech Center cannot sort out in writing or over the phone. At that point, visiting the customer in person is the only option left. “If that’s going to work, though, we have to know that the material is the problem,” Wenzeis explains. Before he or one of his colleagues steps in as a troubleshooter, the Tech Center team first goes about systematically isolating the problem.

48 Hours – 80 Percent

They start out by finding out exactly which material, which machine and which mold the customer is using in order to pinpoint the problem. WACKER retains a reference sample of every product generated for a given customer order, and the team can use this as a basis for initial testing. If necessary, the team will also ask the customer to send a current material sample, which is then subjected to a comprehensive battery of tests at the Tech Center. The process takes the team through a number of interfaces to find a solution. And if the situation absolutely calls for it, troubleshooting will even take place outside of the Tech Center, anywhere in the world, and within a few days – often within 48 hours. The experienced chemical and applications engineers at the Tech Center rarely need longer than that to crack a case, and frequently find the answer in less time. That is true in 80 percent of the cases, at any rate. Sometimes, however, the root of the problem turns out to be quite different from what was originally assumed. Still, the team does not leave any mysteries unsolved: they simply take a completely new approach.

Services Ranging from Customer-Specific Developments to Market-Ready Products

Its decades of expertise make WACKER more than just the market leader in solid and liquid silicone rubber grades – the company also plays an active role in advancing innovation. That’s why troubleshooting is just one part of what the Tech Center does. The main purpose of the center is to test novel products and ones that individual customers have requested – one of the Tech Center’s specialty services, as Wenzeis explains: “We give our customers a full range of consulting services. We don’t stop with helping them find the right materials for their individual applications – we also advise them on suitable processes, and on selecting appropriate machines and the right mold. When we do that, we work closely with our colleagues in the laboratory, in Technical Marketing, in Technical Support and with the sales manager responsible for that customer – that’s the person our customers always turn to first.”

Tech Center Services Reduce Time-to-Market

Customers can use these services to broaden their own expertise. Plus, the Tech Center also provides customized training programs at the customer’s site. “If they want, we can also bring the machine manufacturers and mold-makers on board. All told, the unique service that the Tech Center offers throughout the world is highly customized.” Wenzeis adds, “For our customers – especially those that haven’t been in this market for very long – we shorten the time-to-market for them and secure important competitive advantages.”

- +1 Like

- Add to Favorites

Recommend

- Wevo Developed Silicones and Polyurethanes with a Lower Hydrogen Permeability Used as Adhesives and Sealants for PEM fuel cells

- Silicon Labs Simplifies IoT Development with Simplicity Studio 5

- Silicon Labs Strengthens Isolated Gate Driver Portfolio

- News | Silicon Labs and Amazon Collaborate on Sidewalk, a New Shared Network for IoT Consumer Devices

- Silicon Labs Z-Wave Wireless Selected for Johnson Controls Next Generation Qolsys Smart Home Panel

- Silicon Labs Expands Isolated Gate Driver Product Family Ideal for Hybrid and Electric Vehicles (EV)

- Software Speeds Development of IEEE 1588 System Integration | Silicon Labs

- Silicones From Wevo Support The Battery Market to Meet ATEX Requirements, Offering Excellent Thermal Mitigation Properties

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.