What Is an Ultra Thin LiPo Battery?

The Lithium-ion battery (LIB) has revolutionized our lives and is widespread from small-scale devices such as mobile phone to emergency distributed power supply, electric vehicle, etc. Lithium-ion batteries are evolving even now. Many current types of research for LIB focus on life extension, energy density, safety, cost reduction, and charging speed. thin film LIB is one of the forms of LIB, it has attracted much interest for use as power sources of smart cards, implantable medical devices, micro-sensors, and soon.

Fig.1

What is an Ultra Thin LiPo Battery?

The thin film LIB is composed of the anode, cathode, and electrolyte with thick-nesses on the order of microns. As the demands for safety, higher energy density and other performance metrics increase, research into anode, cathode, and elec-trolyte materials has been rapidly progressing. Cathode materials are often mixed metal oxides involving lithium ion such as LiCoO, and LiMnO. Anode materials are lithium metal, carbon-based materials, and inorganic compounds. Both the cathode and anode materials are film, chosen for their ability to intercalate, and de-intercalate lithium ion while maintaining their structural integrity.

Established Techniques for Ultra Thin LiPo Battery

The use of highly functionalized thin films in various electronic devices has made life comfortable and this is due to the enhanced functional properties of materials at the nano-scale level. At present, the miniaturization of various electronic devices is inevitable as the electronics industry looks at manufacturing thinner and lighter devices , in addition to reduced power consumption. For example, in secondary lithium-ion batteries (LIBs), electrodes employing thinfilms of active materials are preferred over their bulk counterparts due to the muchimproved electronic and ionic conductivity, increased specific surface area andthe ease of controlling the morphology. This means that light and compact power sources with identical energy capacity to their heavier and large counterparts can beeasily manufactured through thin films applications. Owing to the above-mentioned benefits of thin films'applications in LIBs and electrical devices, a considerable number of techniques have been established for the fabrication of these thin films. In this chapter, some of the effective techniques used in the deposition of thin films are described and discussed. The fabrication techniques can be divided into two categories representing gas phase and liquid phase fabrication methods for thin films.

Gas phase fabrication methods

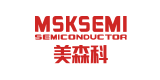

Magnetron sputtering is one of the most well-established techniques that is widely used in the industries to fabricate coatings of many different materials, including metals, semiconductors, and alloys. Thin films fabricated via magnetron sputtering prove to be of superior quality in comparison to those fabricated using other gas phase methods. The schematic representation of the magnetron sputtering set-up is shown in Figure below.

Fig.2

Before deposition, the chamber is evacuated to ca. 10-4 kPa and then refilled with Ar gas which is used as the sputter gas. Using strong electrical and magnetic field, magnetron sputtering employs the bombardment of the selected target's surface by Ar+ ions which are formed as a result of the collision between Ar gas atomsand electrons trapped within the magnetic field. The Ar+ ions are attracted toward the negatively charged target (cathode) and the bombardment leads to the ejection of the targets particles which are then redeposited as a thin film on the substrate placed on the anode, opposite to the target. Depending on the type of power source utilized, magnetron sputtering can be divided into two types namely, direct current (dc) magnetron sputtering and radio frequency (rf) sputtering. While dc magnetron sputtering is relatively cheaper in comparison to rf, only electrically conductive targets like metals or doped semiconductors are used. Additionally, reactive gases such as oxygen or nitrogen gas are used to react with the sputtered materials, in the fabrication of thin films for metal oxides or nitrides, respectively. The technique is referred to as "reactive magnetron sputtering”.

Liquid phase processes

Electrospray deposition (ESD) involves the deposition of charged particles formed as a result of liquid atomization by an electrical force. The atomization of the liquid by electrical force allows for the generation of small particles, of narrow size distribution which can be uniformly dispersed over the substrate and, ESD has been considered as apromising technique for the formation of high-quality layers and films. If the ESD process is carried out at elevated temperatures, thin film formation is achieved through the thermal decomposition of the precursor solution during deposition and the process is referred called “electrospray pyrolysis (ESP).” The schematicrepresentation of the ESD setup is shown in the figure below.

Fig.3

As shown in figure, the ESD method is based on supplying a precursor solution through a metallic capillary which is maintained at high electrical potential. Ideally, the solution forms a Taylor cone at the tip of the capillary and emitted as a solution jet composed of many highly charged droplets that are homogeneously dispersed in the space between the nozzle and the counter metallic plate (substrate holder) by Coulomb repulsion forces. The quality of the resultant thin films can be easily controlled by adjusting variables such as the applied voltage, distance between the atomizing nozzle and, the flow rate, concentration and amount of the precursor solution.

In addition to a very low throughput associated with the ESD technique, thin film deposition on insulating substrates is generally not possible due to charge accumulation on the substrate, which leads to the repulsion of more incoming charged particles. Modifications such as the use of alternating current (ac) and extractor electrodes have been employed to solve the charge repulsion issue and ensure the thin film deposition on insulating substrates via ESD. However, thiscomplicates an initially simple experimental setup.

Ultra Thin LiPo Battery Applications

Due to their unique features, ultra thin LiPo batteries are used in a variety of applications, including:

●Wearable Technology: Smartwatches, fitness trackers, and health monitoring devices benefit from the lightweight and slim design.

●Medical Devices: Ultra thin batteries power medical implants, hearing aids, and other portable medical devices.

●Consumer Electronics: Smartphones, tablets, and other portable gadgets utilize these batteries for their slim profile.

●Smart Cards: Credit cards, ID cards, and other smart cards integrate ultra thin batteries to power embedded electronics.

●Flexible Electronics: Emerging technologies like foldable phones, e-papers, and flexible displays use these batteries for their flexibility and thinness.

●IoT Devices: Small, interconnected devices in the Internet of Things (IoT) ecosystem often rely on ultra thin batteries for power.

Grepow Ultra Thin LiPo Battery Solutions

Grepow's Ultra Thin LiPo Battery is a cutting-edge pouch cell type battery with an incredibly slim profile, measuring just 0.4mm in thickness. This makes it perfect for ultra-narrow applications where space and weight are critical. The battery can be customized in various shapes and sizes to meet specific customer requirements, making it ideal for use in wearable devices, medical equipment, miniature electronics, and IoT devices. Despite its compact size, it delivers reliable performance and offers a space-saving solution for modern electronic devices. Some of their solutions include:

●Customizable Designs: Grepow offers bespoke battery designs to meet specific customer requirements, including unique shapes and sizes.

●High Performance: Their batteries are designed to deliver high energy density and long cycle life, ensuring reliable performance.

●Safety and Reliability: Grepow incorporates multiple safety features in their batteries to prevent overcharging, overheating, and other potential hazards.

●Wide Range of Applications: Their ultra thin batteries are used in medical devices, consumer electronics, wearables, and more.

●Advanced Manufacturing: Grepow uses state-of-the-art manufacturing processes to produce high-quality batteries that meet stringent standards.

- +1 Like

- Add to Favorites

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.

Recommend

Sodium-ion Battery vs Lithium-ion Battery: What’s the Difference?

2024-03-14 - Technical Discussion As the demand for energy storage solutions grows, researchers are exploring alternative technologies to the ubiquitous lithium-ion batteries. One such contender is the sodium-ion battery, which offers potential advantages but also faces significant challenges. In this article, we will delve into the key differences between sodium-ion and lithium-ion batteries, evaluating their strengths, weaknesses, and prospects for the future.

Thin Film Lithium-ion Battery Vs Lithium-ion Battery: What’s the Difference?

2024-08-22 - Technical Discussion In the rapidly evolving world of battery technology, thin film lithium-ion batteries have emerged as a promising alternative to traditional lithium-ion batteries. These batteries, with their ultra-thin structure and solid-state electrolyte, offer distinct advantages in flexibility, safety, and application potential. This article delves into the fundamental differences between thin film lithium-ion battery and conventional lithium-ion battery, exploring their respective structures, manufacturing processes, and applications across various industries.

Battery material - lithium ion battery separator

2025-08-14 - Technical Discussion Because of its insulating property, good thermal stability and excellent electrolyte retention capacity, the porous inorganic membrane has been taken into account as lithium-ion battery separator for the first time. This dissertation is focused on lithium-ion battery system, and aim at improving the safety performance and rate capability of the battery. The porous Al2O3, SiO2, and AAO separators have been prepared.

Lithium-ion Battery Cycle Life VS. Calendar Life VS. Shelf Life

2024-01-04 - Technical Discussion Lithium-ion batteries have become an integral part of our daily lives, powering everything from smartphones to electric vehicles. As these batteries play a crucial role in various applications, understanding their life expectancy is essential. In this article, we will explore the concepts of cycle life, calendar life, and shelf life of lithium-ion batteries, shedding light on their individual characteristics and implications.

What is a Silicon Anode Lithium-Ion Battery?

2024-06-19 - Technical Discussion This article delves into the specifics of silicon anodes, their benefits, and the challenges they present.

Grepow 12V 100Ah LiFePO4 battery

2025-08-06 - Product Introduction Grepow 12V 100Ah LiFePO4 battery:Used on home solar system, UPS and other industrial applications. Embeds BMS system for Lithium Iron Phosphate cell (LiFePO4) that offers a high level of safety and long lifespan. And Grepow Lithium Iron Phosphate modular batteries are drop-in replacement for lead-acid batteries.

What is a Lithium-ion Battery Cell, Battery Module, and Battery Pack?

2024-02-01 - Technical Discussion In the fast-paced world of technology and electric vehicles, lithium-ion batteries have become the backbone of energy storage solutions. Whether it‘s powering your smartphone, laptop, or electric car, these high-energy-density batteries have revolutionized the way we store and utilize electrical energy. In this article, we will delve into the components that make up a lithium-ion battery system, exploring the intricacies of battery cells, battery modules, and battery packs.

5 Factors That Affect the Lithium Ion Battery Life

2022-06-05 - Manufacturer News Grepow talks about 5 Factors That Affect the Lithium-Ion Battery Life.

What Is a BMS Battery?

2025-06-18 - Technical Discussion A Battery Management System (BMS) is a critical electronic system integrated into rechargeable battery packs, especially lithium-ion batteries, to ensure their optimal performance, safety, and longevity. It acts as the “brain“ of the battery pack by continuously monitoring and managing various parameters such as voltage, current, temperature, and state of charge (SoC), thereby preventing dangerous conditions and maximizing battery life. This article provides an in-depth exploration of BMS, addressing its functions, necessity, and common user queries.

Grepow Battery will exhibit at 2022 Summer Asia Smart Wearable Exhibition

2022-07-09 - Manufacturer News The bi-annual Asia Smart Wearable Exhibition (ASWE) will be held from July 18 to July 20 at Shenzhen International Convention and Exhibition Center. Grepow will bring its smart wear accessories shaped lithium-ion batteries and button batteries present, booth number: C24 in Hall 4.

Energous Partners with NGK to Enable Maintenance-free IoT Applications via Wireless Power Networks

2022-10-29 - Manufacturer News Energous announced a partnership to develop solutions that combine Energous’ WattUp technology with NGK’s lithium-ion rechargeable EnerCera® battery to enable maintenance-free IoT devices

NMC Battery vs. LCO Battery: What’s the Difference?

2024-10-23 - Technical Discussion When it comes to lithium-ion batteries, two of the most commonly discussed chemistries are NMC (Nickel Manganese Cobalt) and LCO (Lithium Cobalt Oxide). Both are widely used in a variety of applications, from electric vehicles to consumer electronics, but they differ significantly in terms of chemical composition, energy density, cycle life, and cost. Understanding the key differences between NMC and LCO batteries is essential for choosing the right battery for specific applications, whether you‘re powering a smartphone or an electric vehicle.

Recycling and Regeneration of Lithium Batteries

2022-03-17 - Industry News Under the pursuit of economic and environmental protection, the production and demand of lithium batteries have grown in recent years. Decommissioned lithium batteries are known as high-grade mines, coupled with the price and mining of raw materials, so the recycling value is obvious.

What Is a NMC Battery?

2024-03-15 - Technical Discussion NMC batteries are a type of lithium-ion battery that has gained popularity in various industries due to their high energy density and long lifespan. These batteries use a combination of nickel, manganese, and cobalt in the cathode, which allows them to store a large amount of energy in a relatively small and lightweight package. NMC batteries are used in a wide range of applications, including electric vehicles, portable electronics, and renewable energy systems.

eVTOL Battery vs EV Battery: What’s the Difference?

2024-08-24 - Technical Discussion While both eVTOL and EV batteries share similarities in their reliance on lithium-ion technology and the need for safety, durability, and performance, the operational demands of eVTOLs push the boundaries of battery technology further. eVTOL batteries must meet more stringent requirements, including higher discharge rates, rapid charging capabilities, and exceptional safety standards to ensure reliable performance in flight.

Electronic Mall

Auth. Dist.

Auth. Dist.

Auth. Dist.

Auth. Dist.

Auth. Dist.

Auth. Dist.

Auth. Dist.

Auth. Dist.

Auth. Dist.

Auth. Dist.

Auth. Dist.

Auth. Dist.

Auth. Dist.

Auth. Dist.

Auth. Dist.

Auth. Dist.

Auth. Dist.

Auth. Dist.

Integrated Circuits

Discrete Components

Connectors & Structural Components

Assembly UnitModules & Accessories

Power Supplies & Power Modules

Electronic Materials

Instrumentation & Test Kit

Electrical Tools & Materials

Mechatronics

Processing & Customization