Recycling and Regeneration of Lithium Batteries

Under the pursuit of economic and environmental protection, the production and demand of lithium batteries have grown in recent years. Decommissioned lithium batteries are known as high-grade mines, coupled with the price and mining of raw materials, so the recycling value is obvious.

The global demand and the proportion will both rise

Benefiting from the global trend of energy conservation and emission reduction and the EU carbon emission agreement, the global lithium electricity market has entered a period of rapid demand development after 2018. According to Deloitte data, from 2017 to 2020, the global demand for lithium-ion batteries continued to rise, and the annual compound group growth rate reached 22.17%, of which the power battery installed capacity accounted for nearly 18 percentage points increased. In 2020, the global demand for Li-ion batteries reached 279GWh, while power batteries reached 54.5%.

It is expected that as the global penetration rate of electric vehicles will continue to improve, the compound annual growth rate of 34.4% from 2021-2025 will be 34.4%, and in 2025, the overall global demand for lithium battery will reach 1223GWh, power battery accounts for 75.2%.

In other words, the global demand for lithium batteries and the proportion of power batteries will both rise steadily.

Figure 1. Global Li-ion demand (installed) and forecast (in∶GWh, %) for ∶ 2017-2025

Source: Deloitte Forward looking Industry Research Institute collation @ Forward-looking economist, APP

Raw material prices of lithium batteries are high

The raw materials of lithium battery mainly positive and negative materials, electrolyte, diaphragm and fluid, etc. . Among them, cathode materials are the most critical raw material for lithium batteries, including lithium carbonate and lithium hydroxide. Since 2020, the factory price of battery grade lithium carbonate has increased from the minimum of $6502 to $27093 each ton or more; the market transaction price of lithium hydroxide has increased from the minimum of $6657/ton to between $26319-27867/ton. (according to the China’s website in November 2021)

High-grade metal mine

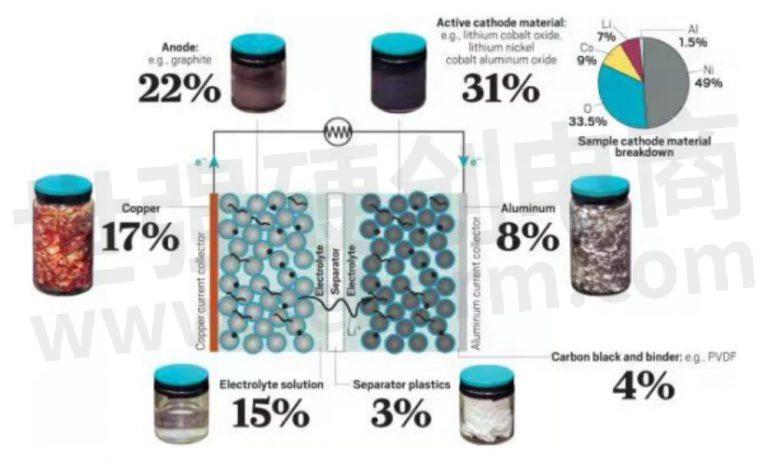

Figure 2. Lithium battery components

Source: the picture from website

Li-ion battery (LIB) contains a lot of Co, Li, Mn, and other valuable metals, so it can be said that spent LIB is a high-grade metal mine. Lithium hexafluorophosphate is easy to decompose and catabolite bind to steam to form hydrofluoric acid. At the same time, organic electrolytes are easily decomposed into formaldehyde and harmful gases such as ketones, which seriously threaten people’s health. From the perspective of resource recycling and environmental protection, the recycling of waste lithium-ion batteries is of great significance.

As the popularity of electric vehicles starts to grow explosively, so does the pile of spent lithium-ion batteries that once powered those cars. Reasonable disposal of retired lithium batteries can promote the development of renewable and sustainable energy. The methods of separating electrode material from aluminum foil and copper foil are highlighted here.

Methods introduction

1 ) Method of separating collecting fluid and electrode materials

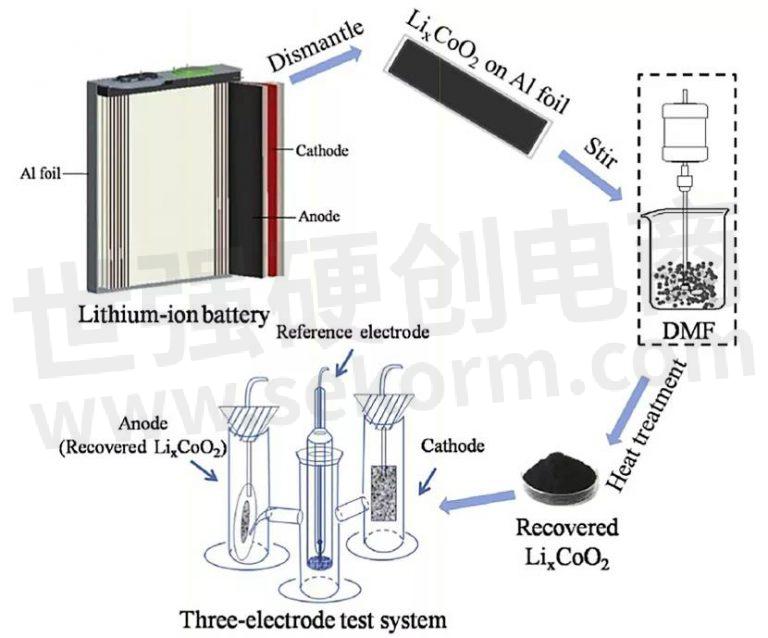

Figure 3. Process of recovering positive electrode materials using DMF

Source: the picture from website Electrochemical person

2 ) Separation of foil of aluminum/copper from electrode material by heating

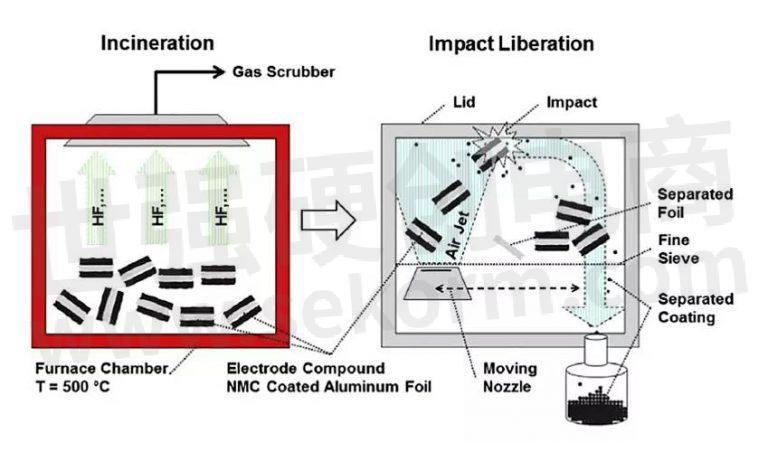

Figure 4. Experimental apparatus for releasing the electrode material by incineration and shock

Source: the picture from website called Electrochemical person

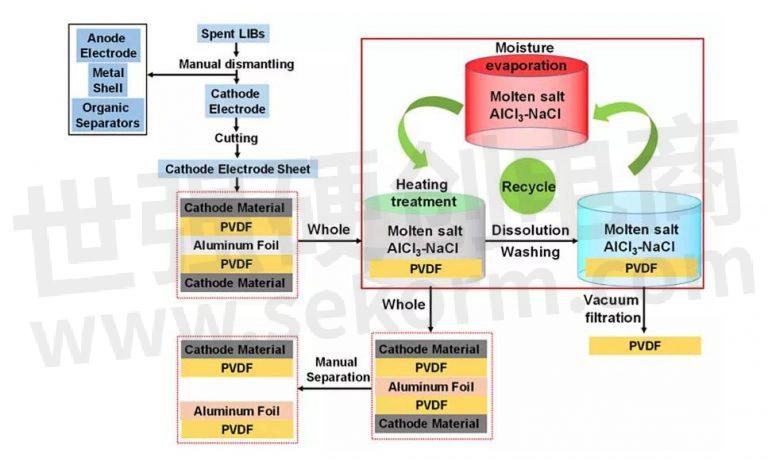

Figure 5. Flow chart of the method for separating cathode material and complete aluminum foil using low-temperature molten salt

Source: the picture from website called Electrochemical person

3 ) Separation aluminum/copper foil from electrode material by mechanical method.

- +1 Like

- Add to Favorites

Recommend

- Can Lithium Batteries and Lead Acid Batteries be Used Together?

- Grepow Lithium Batteries for Automated Guided Vehicles (AGV)

- Things You Need to Know About CCC Certification for Lithium Batteries

- SLKOR DW01 Protective Circuit for Lithium Batteries With the Function of 0V Charging Enabled

- YDSTECH IPC-8610 Industrial Computer for Rapid CT Inspection of Lithium Batteries

- Recycling of PV Panels Can Improve the Performance of Lithium Batteries?

- Power Glory ( Lijia) Provide Lithium Batteries for Smart City - ESL Electronic Shelf Label

- Lithium vs Alkaline Batteries – Which is Better?

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.