How Automating Patient Sample Analysis Helps Improves Health Outcomes

Laboratory analysis of patient samples is critical to helping physicians make an accurate diagnosis. Timely and precise sample analysis became even more important as the world navigated the ongoing COVID-19 pandemic. Any errors within that process can negatively impact outcomes for patients.

The Emergency Care Research Institute (ECRI) publishes a yearly list of top patient safety concerns. Diagnostic errors have consistently ranked as a top concern. The 2022 report adds a new wrinkle, noting that cognitive biases during patient evaluation have increased, raising the risk of misdiagnosis during sample analysis.

ECRI also notes that the industry is currently dealing with a shortage of qualified lab technicians. A heavier workload put on the remaining staff could further exacerbate the problem of inaccurate patient diagnoses.

Other industries have already embraced automation to boost workforce output. SelectUSA noted an 0.8% rise in overall productivity for every 1% added of automation added. There can be financial benefits to expanding automation, with recent findings from the 2021 CAQH Index showing that the medical industry has reaped over $166 billion in savings through automation.

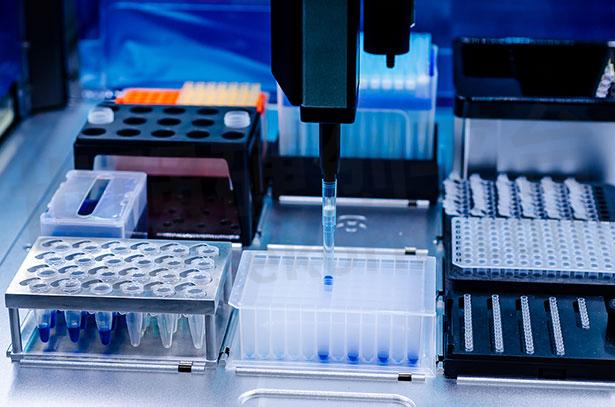

Using Lab Automation in Liquid Handling

The proposed MMR920 MEMS pressure sensor looks to add automation to laboratory liquid handling applications. It detects pressure changes within 1/1000 of an inch of a water column. The MEMS sensor employs lab automation by confirming the extraction of 10 microliters of liquid, which then gets released with a pipette.

MMR920 Technology Demonstration

First, technicians attach a syringe to the MEMS sensor connected to a laptop running the sensor application software for measuring syringe pressure. The low-pressure range technology is ideal for the need to extract and dispense low volumes of liquid.

MEMS sensors reduce errors that occur when clinical analyzer equipment runs short on reagents. Lab techs receive an alert to address the problems, cutting down on laboratory errors that impact patient sample analysis results.

The compactness of the MMR920 MEMS sensor should make it easier for lab automation manufacturers to integrate the sensor with various liquid handling instruments. In addition, their structure makes the sensors robust enough to handle applications used in places with high humidity.

The Critical Role of Lab Automation

The modern healthcare world depends heavily on the results of patient sample analysis to make a prognosis or inform treatment decisions. Streamlining standard pre and post-analytical stage steps through automated technology can address many of these issues by lowering the potential of human error impacting the results.

MEMS sensors allow for stability and accuracy when used for liquid measurements and can speed up sampling time. The components that make these tools work play an important role. Another example is the stepping motors that add the desired holding torque to a pipette until it dispenses all contents.

Increased lab automation has the potential to encourage more positive patient outcomes. It can help alleviate issues with staffing by making it easier for current personnel to handle an expanding workload safely and effectively. Providers of MEM sensors and other healthcare automation need quality build components to ensure the durability of the technology.

Quality Lab Automation Technology

MEMS sensors are just one way the health industry is looking to revolutionize current processes. Industry-wide adoption of automation can make the environment safer for patients while helping practitioners meet their goal of delivering high-quality healthcare to the patient. Providers must continue looking for ways to push forward with laboratory automation advances, including the components used to construct the lab automation technology.

- +1 Like

- Add to Favorites

Recommend

- Mitsumi MMR920 Pressure Sensor is Ideal for Water Level Measurement in a Smart Water Bottle Due to Its Small Size, Low-cost, and Liquid Compatibility

- Mitsumi MMR920 Grass Bag Fill Sensor for Robotic Mowers, with Ultra-Small Footprint and High Sensitivity

- MITSUMI Announced that ABLIC, the Company‘s Consolidated Subsidiary, Had Decided to Acquire the Medical-related Business Operated by Socionext from Socionext

- MinebeaMitsumi Installs Large-Scale Solar Power Generation Systems at Cebu Plant

- Mitsumi Has Developed CMI-BD001 Standard Type Onboard Interface Connection Unit for Vehicle Market

- MinebeaMitsumi Thin Lens Challenge toward the Future of Lighting

- MinebeaMitsumi Notice Regarding Construction of Second Plant in Cambodia and Solar Power Generation Business in Cambodia

- MITSUMI Onboard FAKRA Connector Series is Featured with a High-frequency Characteristic from 0 to 4GHz

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.