WACKER Presents Silicone Materials for Enhancing the Safety of Lithium-Ion Batteries

WACKER, the Munich-based chemical company, will be presenting a selection of silicone products for battery technology and electromobility at this year’s Battery Show Europe. The focus will be on the potting compounds ELASTOSIL® CM 181 and ELASTOSIL® CM 185. The latter is a recent development which will be premiered at the show. Both products boost battery safety in electric vehicles. They ensure the reliable operation of battery cells and prevent fire from spreading in the event of thermal runaway in a cell.

ELASTOSIL® CM 185 has been specifically developed for use as a potting compound for the vent and cell contacting system of lithium-ion batteries. The product falls into the category of RTV-2 silicone rubber compounds, i.e. a two-component silicone material that vulcanizes at room temperature. The compound is pourable and can be applied by dispensing equipment.

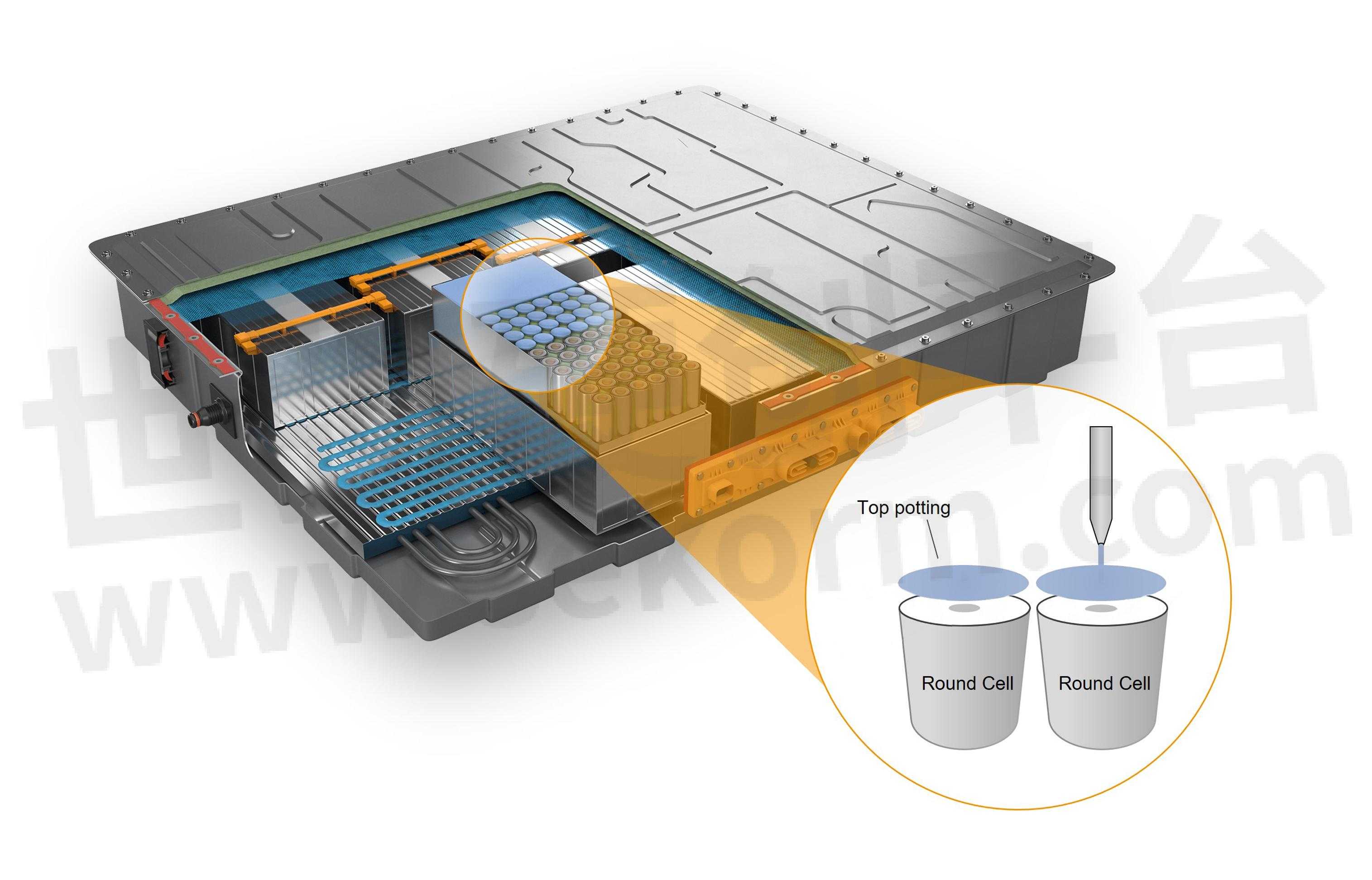

At this year’s Battery Show, WACKER will premier ELASTOSIL® CM 185. This silicone rubber compound is applied to the cell contacting system of the battery modules (see detail, blue) and prevents that a fire spreads from one cell to neighboring cells. (Chart: WACKER)

ELASTOSIL® CM 185 is intended for application to the sensitive vent and cell contacting system of a battery pack. This self-adhesive condensation-curing formulation yields an electrically and thermally insulating elastomer with optimized mechanical properties. When used for potting, it creates a protective layer but does not impair the functionality of the vent.

Should thermal runaway occur in a cell of a battery pack potted with ELASTOSIL® CM 185, the pressure is relieved via the vent and also via the silicone potting compound, without the escaping gases impairing the other cells. The silicone continues to protect all the other cells in the battery pack. Thus, the path of thermal propagation via vent and cell contacting system that gives rise to autoignition of adjacent cells is blocked.

ELASTOSIL® CM 181

The second product highlight to be presented by WACKER at this year’s Battery Show is ELASTOSIL® CM 181. This addition-curing RTV-2 silicone rubber compound rapidly crosslinks to an elastomer at room temperature. The compound has a low viscosity and is very easy to pour. Formulated with a lightweight filler, ELASTOSIL® CM 181 has a defined pore structure that lowers the density of the cured rubber and renders it compressible. The silicone compound also contains a heat-absorbing filler.

This property set renders ELASTOSIL® CM 181 the ideal candidate for filling the gaps between cells in the battery pack or module. Potting serves to isolate the cells electrically and thermally while also providing mechanical support and a protective function. As a result, vibrations, shocks, and thermal expansion of the cells can be absorbed and counterbalanced, without the cell assembly being placed under mechanical stress. In addition, the thermally insulating silicone elastomer hinders further heat transfer via the side-walls of the cells. Potting the spaces between the cells with ELASTOSIL® CM 181 thus ensures more reliable battery-cell operation.

Further Products at the WACKER Booth

Aside from the two aforementioned potting compounds, the chemical group will be showing further silicone products aimed at the battery and electric vehicle sector:

Silicone resin binders for heat-resistant coatings for battery covers or mats made from fiber-based composite materials that are inserted into the gap between the anode caps or the safety valve and the battery cover.

Thermally conductive gap fillers and a thermally conductive potting compound for thermal management of lithium-ion batteries and power electronics. These addition-curing silicone products facilitate efficient thermal connection of a component to the temperature-control system.

Silicone sealants for different applications relating to electromobility.

Visit WACKER at the Battery Show Europe 2024 – Booth C-50 in Hall 10.

- +1 Like

- Add to Favorites

Recommend

- WACKER Launches The Liquid Silicone Rubbers ELASTOSIL® LR 3003/90 With a Hardness of 90, Measured in Shore A

- WACKER Has Produced A Liquid Silicone Rubber (LSR) ELASTOSIL® LR Series for 2K Injection Molding

- LEAP Technology Has Developed A Kind of Sensor – Based on WACKER ELASTOSIL® Silicone Films

- WACKER ELASTOSIL® LR Liquid Silicone Rubber Featured with An Improved Fire Protection,Which Means Increasing Safety

- WACKER Engineering Silicones Tech Center in Burghausen

- WACKER Presents Silicone Resins SILRES® H60 A/B and SILRES® H62 C for the Impregnation of Electric Motors

- WACKER Presents Highly Adhesive Silicone Gel for Fixing Electronic Components at COMPAMED 2023

- WACKER’s Polysilicon Production Successfully Certified to IATF 16949

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.