WACKER ETONIS® Additives Have a Doubly Positive effect on Concrete

For stadiums, freeway interchanges, or bold bridge designs – no other material is as versatile and economical as concrete. Thanks to intense research over the past few decades, the property profiles of today’s concrete grades have opened up entirely new applications in the construction industry. And ETONIS® concrete admixtures have played an important role in driving the innovations behind this development. ETONIS® additives have a doubly positive effect on concrete: they improve the behavior of fresh concrete and optimize the qualities of hardened concrete.

Chemistry with an Impact

ETONIS® concrete admixtures are based on vinyl acetate-ethylene (VAE) and are produced by emulsion polymerization of vinyl acetate, a hard, polar monomer, and ethylene, a soft, hydrophobic monomer. As a result, adhesion, flexibility, and hydrophobicity are also the main properties that ETONIS® lends to concrete, and the positive impact of these is evident in both freshly poured and hardened concrete.

Improved Workability

Addition of ETONIS® makes fresh concrete more pliable, which has a positive effect on its flow properties, pumpability and sedimentation stability.

Higher Elasticity

In hardened concrete, ETONIS® lowers the modulus of elasticity while increasing compressive strength, making concrete ductile, even though it is a brittle material on its own. In actual construction applications, this translates to higher tensile and flexural strengths, greater elongation at break, and reduced susceptibility to tearing – advantages anytime absorbing thermal stress, vibrations, or pressure is important.

Better Adhesion

ETONIS® improves cohesion and adhesion in concrete, even bonding on damp substrates and smooth surfaces like metals.

Highly Resistant

In solid concrete, ETONIS® provides outstanding anti-abrasion properties, along with excellent resistance to chlorides dissolved in water. ETONIS® also acts as a protective shield against acids, gases, and other aggressive media.

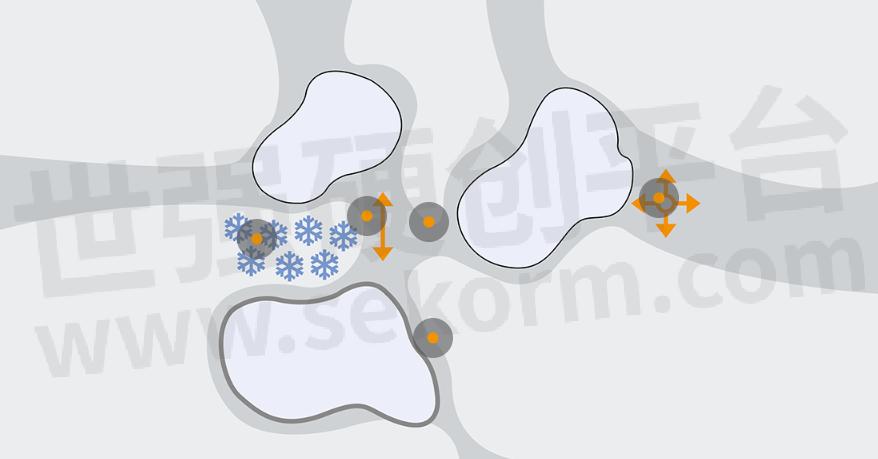

Effects of ETONIS® in Pervious Concrete

For Concrete 2.0

Redefining the Limits of Possibility

Polymeric binders open up new design options for architects and planners. Extra-lightweight, curved components made of architectural concrete, water-absorbent roads, and plazas – projects that would have been unthinkable until just recently but that are now feasible for the first time thanks to polymer modifiers.

Increasing Building Longevity

Today we can improve the performance and longevity of concrete far beyond what was possible in the past. That, in turn, impacts the quality of the building fabric: modern modified concrete doubles the service life of a building.

Building for Greater Sustainability

Today’s infrastructure projects are drawing more attention than ever before. The focus is now no longer on cost alone – project sustainability is important too. Modified concrete has benefited greatly from this trend: modifying materials, after all, reduces the amount of cement used, which prevents unnecessary greenhouse gas emissions.

- +1 Like

- Add to Favorites

Recommend

- Wacker Offers Effective Solutions for Protecting Concrete from Water

- WACKER Engineering Silicones Tech Center in Burghausen

- WACKER’s Polysilicon Production Successfully Certified to IATF 16949

- WACKER Presents Innovative Solutions in Construction and Coatings at PAINTINDIA

- WACKER Has Produced A Liquid Silicone Rubber (LSR) ELASTOSIL® LR Series for 2K Injection Molding

- LEAP Technology Has Developed A Kind of Sensor – Based on WACKER ELASTOSIL® Silicone Films

- WACKER Positions itself as Solution Provider for Silicone-Coated Healthcare Products with New Acquisition

- WACKER Expands Specialty Silicone Production in China

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.