Unimotion Linear Units and Their Integration into Multi-axis Systems Enable the Conversion of Rotation into Linear Displacement

UNIMOTION's linear units are products designed for installation in automated devices. They enable the conversion of circular motion (rotation) into linear displacement (translation) via a toothed belt or ball-screw.

The linear units consist of an aluminium, extruded profile, which mostly serves as housing. The linear units consist of an aluminium extruded profile, which mostly serves as housing. Linear guides with a hardened surface are attached to this profile, along which the carriage runs. The profiles of the linear units are made from aluminium with good corrosion resistance. They are also anodized to achieve greater surface resistance to scratches and shocks. Lubrication of all components is done via one central lubrication nipple.

Built-in ball screws are made from rolling of the material which means that none of the material is being removed in the process. Several different thread steps are available for each size. The maximum length of the ball screw also determines the maximum length of the linear unit. This can be overcome if additional ball-screw supports are used. Both ends of the linear units are made of aluminium alloy that is black anodized, thus achieving increased corrosion and scratch resistance of the surface.

Polyurethane toothed belts with an AT tooth geometry are used in the belt-driven linear units. The load-bearing part of the belt is made of steel wires, which are embedded inside the belt body. The shape of the teeth ensures the transfer of power and movement without slipping and airiness.

Stepper and servo motors are commonly used to drive the linear units. The connection is made with a coupling and a motor adapter that rigidly connects the two elements. The adapter covers and protects the coupling and shafts from possible external damage. In addition to the motor adapter, the motor and the linear unit can also be connected via a motor side drive which positions the motor parallel to the linear unit itself. There are different gear ratios of this motor side drive which simplifies the adaptation of the linear unit to the individual application.

MTV Linear Units

MTV type linear units are spindle driven and have a built-in single rail guide. The profile of the unit is almost square, and the protection strip prevents larger particles from entering inside the linear unit, thus protecting the ball screw and linear guides inside the profile.

They can be used for axes in multi-axis systems, as the weight of the unit is lower due to one guide and a more compact profile. They are also used for basic axes in portal systems and applications where high thrust or traction is required and loads in other directions are lower.

CTV Linear Units

CTV type linear units use two parallel linear guides. This achieves better load transfer in all directions. Due to the two guides, the profile of the linear unit is wider, which further increases its resistance to bending. Two types of trolleys can be installed in a linear unit - longer and shorter - but it is also possible to connect several trolleys in series. This gives a greater number of attachment points at any distance from each other and also increases the maximum loads that the linear unit can withstand.

CTV type linear units are used as independent basic axes of multi-axis systems, as two linear guides allow the unit to transmit much greater forces and moments, and the spindle provides adequate accuracy and force in the direction of travel. CTV units are also used by placing them facing sideways so that the shape of the profile itself ensures sufficient rigidity in the vertical direction. Due to the high force that can be transmitted through the ball screw, they are also suitable for applications of lifting or pushing loads, punching and cutting.

Guides and ball screws are usually protected with a protective strip in these linear units. The construction of the linear unit also allows adaptation for operation in an environment with elevated temperatures or a clean (clean room) environment.

CTJ Linear Units

The shape of the CTJ linear units is similar to the CTV type, except that in these units the motion transmitter is a toothed belt and not a ball screw. Belt driving allows for higher movement speeds, more dynamic movement and much longer strokes. CTJ linear units also have two linear guides built in. The characteristics are similar to the CTV type, except that this type slightly reduces its positioning accuracy, increases the maximum speed and maximum stroke due to the use of the toothed belt, and it is also possible to choose a long or short trolley.

MTJ Linear Units

MTJ linear units are belt driven linear units of the same size as the MTV. These also have only one linear guide installed, and with belt drive, we achieve higher speeds and longer strokes. The option of an additional metal protective strip allows protection of the belt and linear guides.

MTJ linear units are often used in pairs as base axes in multi-portal systems. Several of such linear units can be mechanically connected to the synchronization axes, thus achieving coordinated movement. They are also useful in applications where long strokes and high speeds are required.

With this type, the trolleys of the linear unit can be connected in series, and the advantages are the same as with the CTV type. CTJ linear units can also be tilted to the side, thus reducing the feed in the vertical direction. They are mainly used in applications where long distances and high speeds are required.

Different types of Unimotion linear units

MTJ ECO Linear Units

The MTJ ECO linear unit is an MTJ type derivative. The construction of this unit is simplified to keep components to a minimum. The guide is on the outside of the profile and thus slightly more exposed to external influences.

MRJ Linear Units

MRJ type linear units are a derivative of MTJ units, except that in the case of MRJ units, two round linear guides are installed instead of one rail. The carriage of the linear unit, on the other hand, has ball rollers so that it can run on guides. This type allows extremely high speeds (up to 10 m / s) and quieter operation.

Some types of linear units can be adapted to operate in cleanrooms for which corrosion and wear-resistant elements are installed.

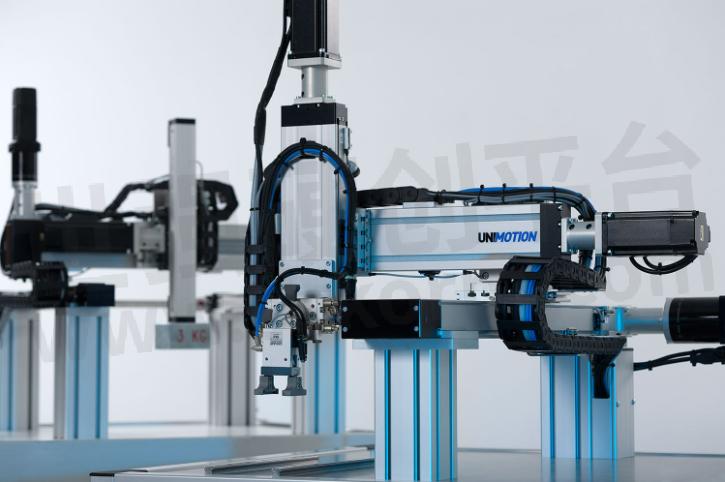

Multi-axis Systems

Unimotion linear units are ready for modular construction of machines and devices. Different types of linear units in different positions can be connected to each other with different connecting elements. They are made of aluminium alloys and are anodized.

Linear units can be connected at right angles. Thus, we get Cartesian robots, where each axis allows a movement parallel to one of the axes of the Cartesian coordinate system. This allows all points within the robot's workspace to be reached. Because the axes can be moved at the same time with proper control, the robot arm can describe any shape, giving the customer additional options for designing the machine or device.

- +1 Like

- Add to Favorites

Recommend

- Unimotion Develops MTV40 Linear Unit with High Repeatability, Large Load Lengths and the Smallest Ball Screw Support System

- UNIMOTION’s German Design Award Winner CTL Linear Unit Offers Repeatability Precision Down to 0.001 mm

- UNIMOTION MGBS and MGTB Mini Linear Units Offer High Speed and Good Positioning Accuracy

- UNIMOTION‘s Stepper Systems Offering a Complete Solution of a Stepper Motor, Drive and Cables

- Unimotion STDL-PN Profinet Drive Providing Modern and Powerful Motion Control Solutions

- Unimotion Linear Unit CTL with a Peak Force up to 2475N and Repeatability up to 0.001mm

- UNIMOTION Linear Motor LMCA Showcase an Excellent Compact Design with Very High Force Density and Low Cogging Force

- UNIMOTION Mini Electric Cylinder MCE and Mini Electric Slider MSCE

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.