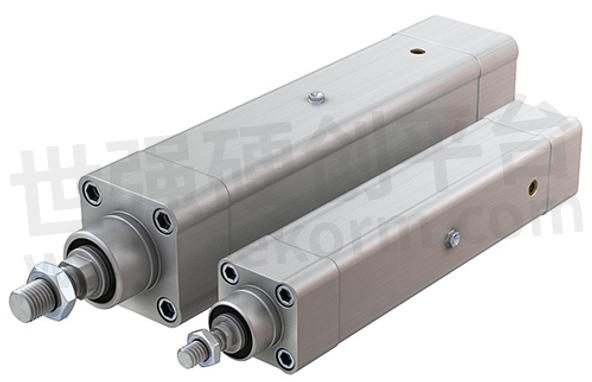

UNIMOTION Electric Cylinders PNCE with a Precision Ball Screw Drive

UNIMOTION's PNCE are electric cylinders with a precision ball screw drive. The electric cylinder is based on the standard ISO 15552. Its outer design and dimensions are very similar to pneumatic cylinders. High performance features such as high speeds, good positioning accuracy, and high repeatability are ensured through a precision ball screw with reduced backlash (preload on request) of the ball nut and non-rotating piston rod. For a long service life, the re-lubrication can be done through a lubrication nipple.

The design with its smooth surfaces enables easy cleaning of the cylinder. In combination with a lubricant class H1 it is also suitable for food & beverage industries. It can be additionally equipped with switches and ISO standard accessories.

The excellent sealing of the components in the cylinder ensures an IP65 protection class and protects the interior of the cylinder from dust, water, and other contaminants. Version IP65CR also offers high corrosion resistance in harsh environments.

IP65 Protection Class (IP65)

The appropriate sealing of the external parts ensures that the electric cylinder has an IP65 protection class. The IP65 protection class of the electric cylinder fulfills the specifications of IEC 60529. The connection for pressure compensation in the cylinder profile ensures the exchange of air between the interior of the cylinder and the environment and prevents the occurrence of excess pressure or negative pressure inside the electric cylinder. It also protects the interior of the cylinder from external media like dust and water.

IP65 Protection Class with High Corrosion Resistance (IP65CR)

It offers high corrosion resistance in harsh environments. The version IP65CR includes all the features of the electric cylinder version IP65. In addition to ensuring high corrosion resistance, all the external parts are corrosion resistant (e.g., the connection for pressure compensation, lubrication nipple, and the connection elements are made of stainless steel). More information about materials is available upon request in the extended material information list.

For Applications in the Food Industry (FI)

The version FI includes all the features of the electric cylinder version IP65CR. It is upgraded with materials suitable for some applications in the food industry. The cylinder is greased with a lubricant class NSF H1. The design with the smooth surfaces of the aluminium profile enables its quick and effective cleaning. During the cleaning, the sealing air can be applied to the connection for pressure compensation. The use for the food & beverage industry is limited by the materials of the electric cylinder. More information about materials is available upon request in the extended material information list.

- +1 Like

- Add to Favorites

Recommend

- UNIMOTION‘s PNCE Electric Cylinder with a Maximum Stroke Length of 1200mm and an Axial Force of up to 16500N

- Unimotion Develops MTV40 Linear Unit with High Repeatability, Large Load Lengths and the Smallest Ball Screw Support System

- UNIMOTION’s German Design Award Winner CTL Linear Unit Offers Repeatability Precision Down to 0.001 mm

- UNIMOTION MGBS and MGTB Mini Linear Units Offer High Speed and Good Positioning Accuracy

- UNIMOTION‘s Stepper Systems Offering a Complete Solution of a Stepper Motor, Drive and Cables

- Unimotion STDL-PN Profinet Drive Providing Modern and Powerful Motion Control Solutions

- Unimotion Linear Unit CTL with a Peak Force up to 2475N and Repeatability up to 0.001mm

- UNIMOTION Linear Motor LMCA Showcase an Excellent Compact Design with Very High Force Density and Low Cogging Force

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.