Thermal Phase Change Sheet: An Innovative Choice to Improve Heat Dissipation Efficiency

In conventional cooling systems, cooling modules are usually installed on or around the heat source surface of the device to actively guide heat. However, there is a common problem in this process: the contact between the heat source surface and the heat sink is not perfect, and a small gap is enough to affect the effective transfer of heat. This is because the heat will encounter air obstruction during the conduction from the heat source surface to the radiator, thereby reducing the heat conduction efficiency.

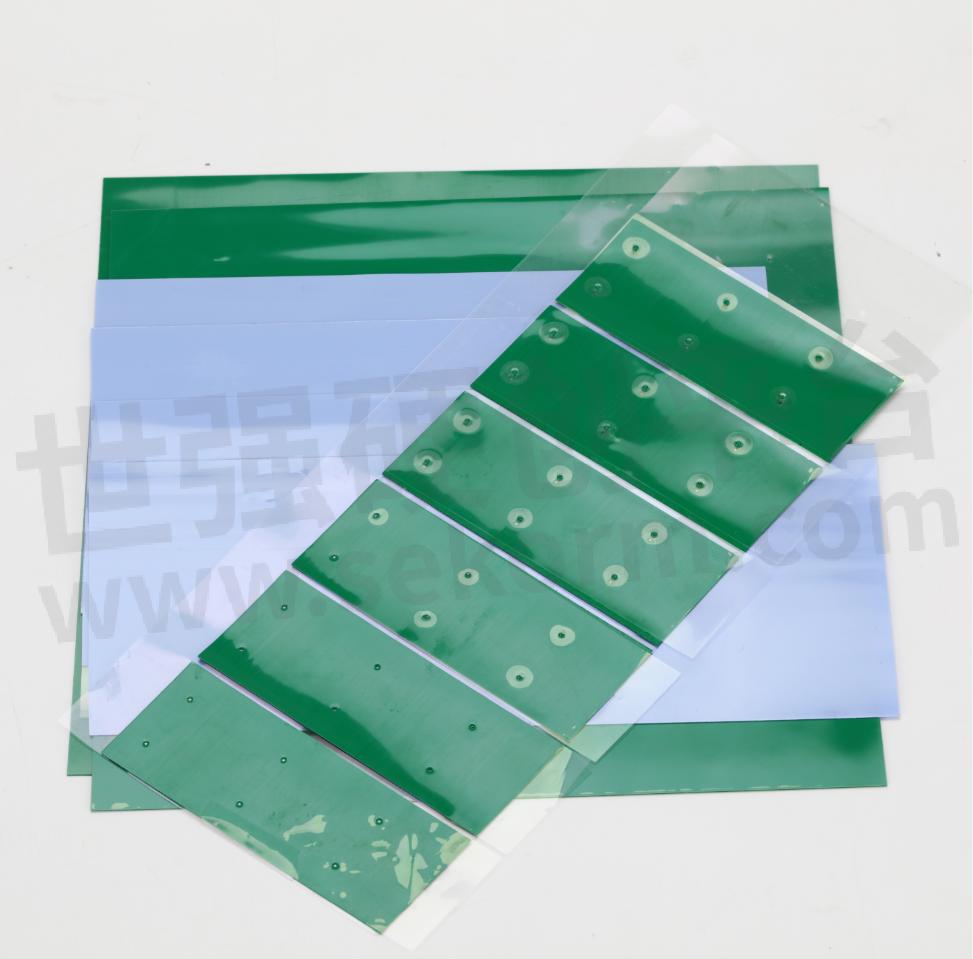

Among many thermally conductive materials, thermally conductive phase change sheets stand out for their unique properties. The characteristic of this material is that it can not only effectively reduce the contact thermal resistance between the heat source and the radiator, but also significantly improve the heat dissipation effect of the device. The key to the thermally conductive phase change sheet is its phase change capability: within a specific temperature range, it will soften but not lose, changing from a solid state to a thick semi-fluid paste. In this process, it can fill the gap between the heat source and the heat sink as much as possible, thereby effectively reducing the contact thermal resistance and improving heat conduction efficiency.

It is worth noting that the thermal phase change sheet becomes soft under working conditions, but once it stops working and the temperature returns to the normal range, it will return to its original state. Compared with other thermal conductive materials, thermal phase change sheets show excellent performance in thermal conductivity efficiency, so they are widely used in scenarios with extremely high heat dissipation requirements, such as high-performance chips and large servers.

To sum up, thermally conductive phase change sheets play a vital role in the heat dissipation system of modern electrical equipment. With the continuous advancement of technology, it is expected that this material will play an important role in more demanding heat dissipation applications, providing strong support for the stable operation and long-term durability of electrical equipment.

- +1 Like

- Add to Favorites

Recommend

- What Are the Characteristics of a Phase Change Thermal Pad?

- What Does the Thermal Resistance of Thermal Conductive Materials Affect?

- Why Does Thermal Resistance Affect the Thermal Conductivity of Thermal Silicone Pad?

- Why Look for A Thermally Conductive Material with Low Thermal Resistance?

- A Brief Description of Thermally Conductive Materials - Thermally Conductive Gel

- Thermally Conductive Materials with Ultra-high Thermal Conductivity

- Comparison of Advantages and Disadvantages of Several Common Thermal Conductive Materials

- Parker Chomerics‘ THERM-A-GAP™ Gel 20 One-component Thermal Interface Material with 2.4W/m-k Thermal Conductivity Ideal for Automotive Industry Applications

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.