FPC Connectors: A Comprehensive Analysis of the Advantages and Disadvantages

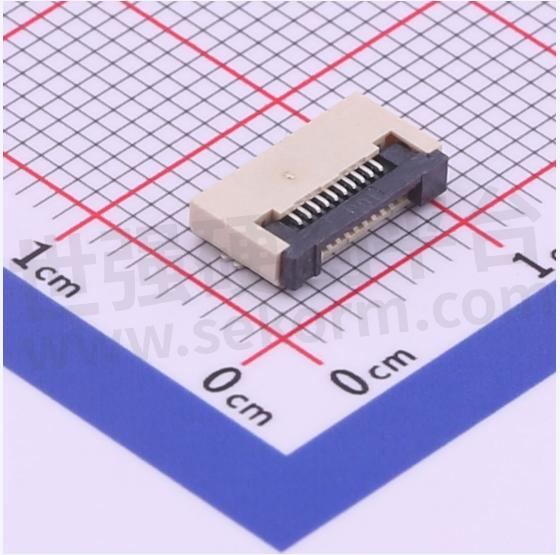

FPC Connectors, also known as Flexible Printed Circuit connectors, are widely used in electronic devices as a connectivity solution. The main advantages of FPC connectors include their lightweight, flexibility, durability, and ease of maintenance, making them suitable for a wide range of industries. However, every product has its limitations, and FPC connectors are no exception. This article will delve into the advantages and disadvantages of FPC connectors.

Advantages

Lightweight and Flexible: FPC connectors have high flexibility and can be freely bent, making them ideal for applications with limited space. Their lightweight and flexible nature makes devices more portable and also facilitates maintenance and upgrades.

High Durability: FPC connectors are designed to have a long lifespan, often reaching millions of cycles. This is due to their excellent material selection and precise manufacturing processes. In environments where frequent usage is expected, FPC connectors maintain long-term stability and reliability.

Quick and Convenient Installation: Due to their flexible nature, FPC connectors can be quickly and easily installed onto circuit boards, significantly reducing installation and maintenance costs.

Diverse Interface Designs: FPC connectors come in various interface designs to meet different application requirements. Whether it's a miniaturized interface or a multifunctional one, FPC connectors offer corresponding solutions.

Disadvantages

Signal Transmission Quality: Although the transmission speed of FPC connectors is continuously improving, the signal transmission quality may be affected in high-frequency or high-data-rate applications.

Cost: The manufacturing cost of FPC connectors is relatively high, resulting in a higher price compared to some other connector options. This may limit their usage in price-sensitive fields.

Repair Difficulty: Due to the thin and flexible nature of FPC connectors, repairing them can be more challenging compared to other types of connectors. If damaged, replacing or repairing them may require more specialized equipment and skills.

Environmental Adaptability: While FPC connectors perform well in most environments, their performance may be affected in extreme conditions such as very high or low temperatures, strong magnetic environments, and so on.

Conclusion

In conclusion, FPC connectors have many significant advantages that make them an ideal choice in many applications. However, like any solution, FPC connectors also have limitations, such as cost, signal transmission quality, and repair difficulties. Therefore, when selecting FPC connectors, a comprehensive evaluation should be conducted based on the specific application requirements and environmental conditions.

- +1 Like

- Add to Favorites

Recommend

- The Difference between FFC Connectors and FPC Connectors

- Detailed Classification of FPC Connectors

- What is the Difference Between FFC and FPC Connectors?

- FFC vs. FPC Connectors: Choosing the Right Connector for Your Application

- Kinghelm Released a High-density and Miniaturized FPC Connector KH-CL0.5-H2.0-6PIN with Insulation Resistance Greater Than 500MΩ

- Kinghelm FPC Connector KH-0.5-H3.25-6PIN: A Tool to Solve Electronic Product Connection Problems

- Buy FPC Connector Products What You Need to Know

- Kinghelm Launched a High-Reliability FPC Connector KH-CL0.5-H2.0-10PIN with a Rated Voltage of 50V, Contact Resistance Less Than 0.03Ω

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.