FFC vs. FPC Connectors: Choosing the Right Connector for Your Application

When it comes to connecting electronic components, FFC (Flat Flexible Cable) and FPC (Flexible Printed Circuit) connectors are two popular options. Understanding the differences between them can help you choose the right solution for your application. This article will explore the key features, advantages, and typical use cases of FFC and FPC connectors to guide your decision-making process.

What Are FFC Connectors?

FFC connectors are designed to connect flat flexible cables, which consist of multiple parallel conductors encased in a thin, flexible film. These connectors are widely used in various applications due to their space-saving design and ease of use.

Key Features of FFC Connectors:

● Compact Design: FFC connectors are incredibly thin, allowing for efficient use of space in compact electronic devices.

● Easy Installation: They often come with a simple locking mechanism that ensures a secure connection without the need for complex assembly.

● Versatile Applications: Commonly used in consumer electronics, automotive systems, and medical devices.

Advantages of FFC Connectors:

● Space Efficiency: Ideal for applications where space is at a premium.

● Cost-Effective: Generally more affordable than other connector types.

● Flexibility: Can bend and twist without damaging the internal wiring.

What Are FPC Connectors?

FPC connectors are used with flexible printed circuits, which are made by etching conductive traces onto a flexible substrate. These connectors offer a more complex design and are suited for applications requiring intricate connections.

Key Features of FPC Connectors:

● High Density: FPC connectors can accommodate a higher number of connections in a smaller area, making them suitable for sophisticated electronic designs.

● Customization: The printed circuit can be tailored for specific applications, allowing for unique layouts and functionalities.

● Durability: FPC connectors often have enhanced resistance to wear and tear, making them ideal for demanding environments.

Advantages of FPC Connectors:

● Complex Design Capability: Excellent for applications that require high-density connections and intricate routing.

● Robust Performance: Typically provide better electrical performance and stability than FFC connectors.

● Reduced Weight: Lighter than traditional rigid PCBs, making them suitable for portable devices.

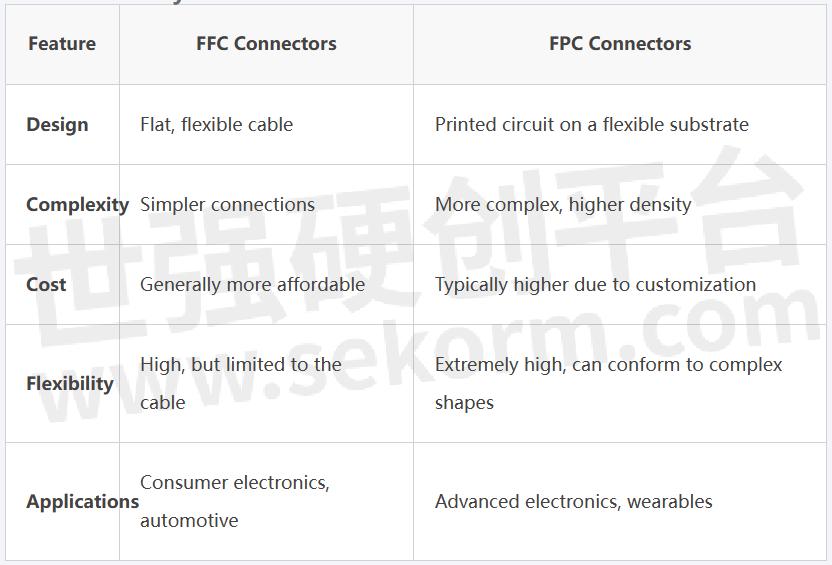

FFC vs. FPC: Key Differences

Choosing the Right Connector

When deciding between FFC and FPC connectors, consider the following factors:

1. Application Requirements: If your application demands high-density connections and customization, FPC connectors may be the better choice. For simpler, cost-effective solutions, FFC connectors are ideal.

2. Space Constraints: Both connectors are designed for compact applications, but FFC connectors are often more suited for environments where space is severely limited.

3. Budget: FFC connectors typically offer a more cost-effective solution, while FPC connectors may require a higher initial investment due to their complexity and customization.

4. Durability Needs: If your application is subject to wear and tear or requires robust performance, FPC connectors generally provide greater reliability.

Conclusion

FFC and FPC connectors each have their unique features and advantages, making them suitable for different applications. By understanding their differences and considering your specific requirements, you can make an informed decision on which connector is right for you. Whether you opt for the simplicity of FFC connectors or the advanced capabilities of FPC connectors, ensuring a proper connection is essential for the performance and longevity of your electronic devices.

- +1 Like

- Add to Favorites

Recommend

- Kinghelm KH-FFC-A0.5-40P-150MM: High-Performance FFC Flat Cable Leading a New Era in Electronic Connections

- Kinghelm’s 26 Pins FFC flexible flat cable KH-FFC-V0.5-26P-100MM, Features A 0.5mm Pitch, A Total Length of 100mm

- The Difference between FFC Connectors and FPC Connectors

- Kinghelm‘s FFC Connection Cable KH-FFC-V1.0-29P-100MM with Flat Shape and High Flexibility

- Kinghelm Launched 32-pins FFC Connection Cable KH-FFC-A0.5-32P-100MM with the Total Length of 10cm

- KYOCERA Introduces 0.5mm-pitch One-Action-Lock FPC/FFC Connectors 6893 Series Bringing 2x Improvement in Foreign Matter Removal Performance

- Kinghelm‘s FFC Connection Cable KH-FFC-V0.5-21P-100MM with 21 Pins, a Pitch of 0.5mm, and a Total Length of 100mm

- FFC FPC Connector: The Key to Seamless Electrical Connections

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.