ROGERS CLTE-AT™ Circuit Materials Excellent Dimensional Stability High Degree of Phase Stability vs. Temperature

CLTE-AT™ laminates represent the commercial version of the CLTE™ product line. CLTE-AT laminates use the common building blocks developed with CLTE-XT™ laminates, but with some changes to make the product more affordable. This results in a higher dielectric constant (3.00) and a slightly different thickness than the CLTE-XT laminates.

CLTE-AT micro dispersed ceramic PTFE composites utilize a woven fiberglass reinforcement to provide the highest degree of dimensional stability, critical in multilayer designs. CLTE-AT laminates are in a “League of their Own” for registration when utilizing thin substrates (i.e. 0.005” and 0.010”).

CLTE-AT laminates have “Best-in-Class” Insertion Loss (S21) and Loss Tangent (0.0013) in the commercial marketplace and are second only to CLTE-XT laminates.

ROGERS’ CLTE-AT laminates were designed to provide a quality peel strength without having to resort to the utilization of the lossier, rougher coppers prevalent in competitive products to achieve acceptable copper adhesion.

CLTE-AT laminates have Low CTE xyz and Very Low TCEr for applications that require Electrical Phase Stability, Dk Stability, and Mechanical Stability well over a -55 to 150℃ Operating Temperature. CLTE-AT laminates continue the competitive advantages of CLTE laminates (dimensional stability, low absorption of moisture and processing chemicals, ease of processability). The higher thermal conductivity of CLTE-AT laminates improves heat transfer relative to alternative materials and enables better power handling.

Features and Benefits:

Superior signal integrity

• Ceramic/PTFE Microwave Composite

• Mechanically more robust and more dimensionally stable than alternatives

• Lowest Insertion Loss in Commercial Class

Excellent thermal/mechanical performance characteristics

• Very Low Loss Tangent (0.0013)

• Electrical Phase Stability vs. Temperature

• High Thermal Conductivity

• Tight Dielectric Constant (±0.04) and Thickness Tolerance

Woven glass reinforcement

• Excellent Thermal Stability of Dk and Df

• Phase Stability across temperature

• High Degree of Dimensional Stability required for complex, multilayer boards

• Excellent CTE in X, Y and Z

Typical Applications:

• Automotive Radar & Adaptive Cruise Control Applications

• Microwave Applications/RF Applications

• Phase Sensitive Antennas/Temperature Sensitive Antennas

• Phase Sensitive Electronic Applications

• RF Filters and Microwave Filters

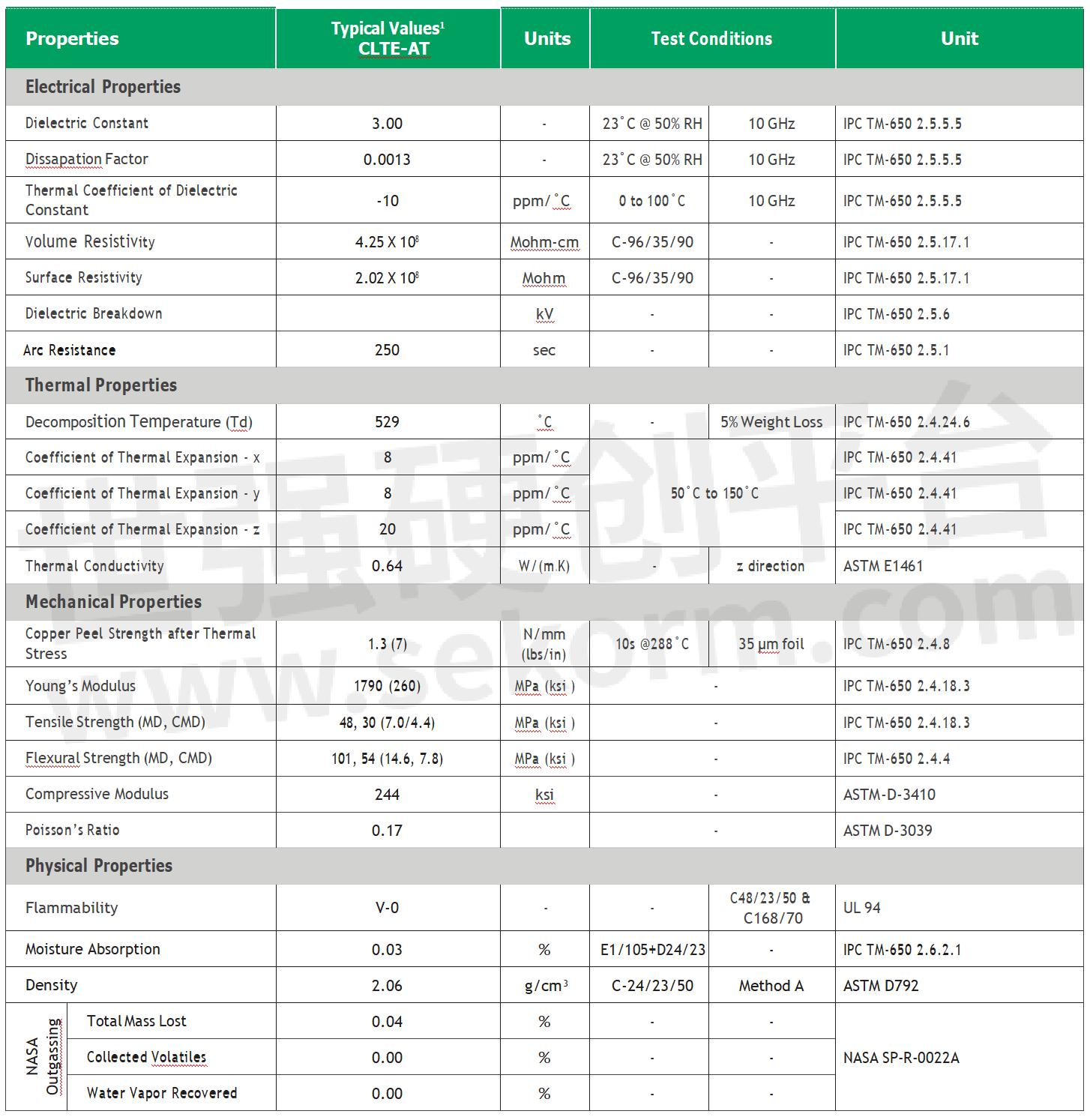

Standard Properties Table

Typical values are a representation of an average value for the population of the property. For specific cation values contact Rogers Corp.

- +1 Like

- Add to Favorites

Recommend

- Rogers Announces Acquisition of Silicone Engineering

- Sekorm Became an Authorized Distributor of Rogers

- Rogers Announces Termination of Merger Agreement with DuPont

- Rogers Corporation Announces Further Actions to Streamline Operations and Drive Margin Improvement

- Rogers Corporation Announces Intention to Consolidate Manufacturing Facilities for RO3000® and RO4000® Product Lines

- Rogers Corporation Introduces New Water-Resistant Flexible Heater Substrate

- Rogers Expands Capabilities and Services with New Application Laboratory

- Rogers‘ Micro Channel Coolers (MCC) in High Performance Computing (HPC) Applications

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.