What are the Advantages of Laminated Design Lithium Thin Film Batteries?

Judging from the final battery product, battery products made by the lamination process have higher energy density, more stable internal structure, higher safety, and longer life than those made by the winding process. Battery cells using the winding process have lower space utilization due to the curvature at the winding corners; while the lamination process can fully utilize the battery space.

● Higher energy density

Battery cells using the winding process have lower space utilization due to the curvature at the winding corners; while the lamination process can fully utilize the battery space. Therefore, under the same volume of battery cell design, the energy density is also increased accordingly.

● The structure is more stable

During the use of the battery, due to the embedding of lithium ions, both the positive and negative electrode plates will expand.

For wound battery cores, because the internal stress of the inner and outer layers at the winding corners is inconsistent, the battery core will undergo wavy deformation, which will lead to a deterioration of the battery interface, uneven current distribution, and the internal structure of the battery will become increasingly uneven. Stable, and this process will accelerate.

However, batteries using the lamination process will expand during repeated use, but generally speaking, the expansion force of each layer is similar, so the interface can be kept smooth.

● Higher security

The expansion and contraction of the pole pieces, the stretching of the separator, etc. will cause the deformation of the battery core, ensuring that the deformation of the battery core is minimal, which is also a guarantee of battery safety.

During the winding process, the pole pieces at both ends are bent, and the coating material will undergo large bending deformation; at the same time, problems such as powder loss and burrs are prone to occur at the bends; the pole pieces and diaphragm are subject to tension, which is prone to wrinkles and Uneven problem. Laminated batteries have higher cell safety due to uniform force and small deformation.

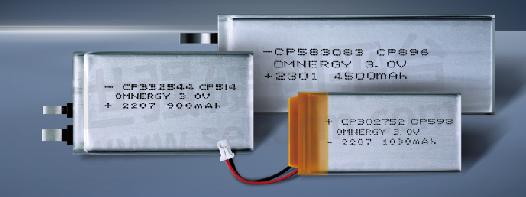

Lijia's laminated structure Lithium Thin Film Batteries adopts a laminated design and introduces a large-area independent current collector. Metal lithium is only used as an active material and all participates in the electrochemical reaction to be fully utilized, fundamentally solving the problem of residual metal lithium. Make batteries more efficient, safe and environmentally friendly. The lithium manganese soft pack batteries produced by Lijia Technology Co., Ltd. are complete in model and variety. They can be made according to the customer's requirements, and can be welded and terminals added.

Fig.1

- +1 Like

- Add to Favorites

Recommend

- How Lithium Polymer Batteries are Made?

- Can Lithium Batteries and Lead Acid Batteries be Used Together?

- Things You Need to Know About CCC Certification for Lithium Batteries

- Lijia CR123A Lithium Manganese Cylindrical Batteries with the Single Battery Rated Voltage of 3V

- SEMITEC Develops FT-R Ultra-Thin Glass Substrate Thin-Film Thermistor Sensors, 10 Times Faster Than Conventional Surface-Mounted Thermistors

- Recycling and Regeneration of Lithium Batteries

- Grepow Lithium Batteries for Automated Guided Vehicles (AGV)

- Thin Film Lithium-ion Battery Vs Lithium-ion Battery: What’s the Difference?

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.