Why Can the Servo Motors Accurately Control the Rotation of the Model Aircraft?

Presumably, fans of model aircraft will not be unfamiliar with steering gear. RC servo gear plays an important role in model aircraft, especially in fixed-wing aircraft models and ship models. The steering, take-off and landing of the aircraft must be controlled by the steering gear. Wings rotate forward and reverse. This requires the traction of the servo motor gear.

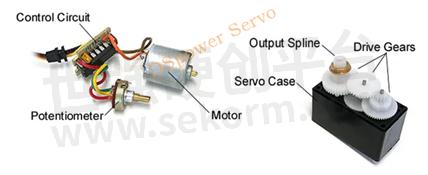

Servo motors are also known as micro servo motors. The structure of the steering gear is relatively simple. Generally speaking, it consists of a small DC motor (small motor) and a set of reduction gears, plus a potentiometer (connected to the gear reducer to function as a position sensor), a control circuit board ( Generally includes a voltage comparator and input signal, power supply).

Servo Different from the principle of stepper motor, it is essentially a system composed of DC motor and various components. The stepper motor relies on the stator coil to be energized to generate a magnetic field to attract the permanent magnet rotor or act on the reluctance core stator to rotate to a specified position. In essence, the error is very small, and there is generally no feedback control. The power of the mini servo motor of the steering gear comes from the DC motor, so there must be a controller that sends commands to the DC motor, and there is feedback control in the steering gear system.

The output gear of the reduction gear group inside the steering gear is essentially connected with a potentiometer to form a position sensor, so the rotation angle of this steering gear is affected by the rotation angle of the potentiometer. Both ends of this potentiometer are connected to the positive and negative poles of the input power supply, and the sliding end is connected to the rotating shaft. The signals are input together into a voltage comparator (op amp), and the power supply of the op amp is terminated to the input power supply. The input control signal is a pulse width modulated signal (PWM), which changes the average voltage by the proportion of the high voltage in a medium period. This input voltage comparator.

By comparing the average voltage of the input signal with the voltage of the power position sensor, for example, if the input voltage is higher than the position sensor voltage, the amplifier outputs a positive power supply voltage, and if the input voltage is higher than the position sensor voltage, the amplifier outputs a negative power supply voltage, that is, a reverse voltage. This controls the forward and reverse rotation of the DC motor, and then controls the rotation of the steering gear through the output reduction gear set. Just like the picture above. If the potentiometer is not bound to the output gear, it can be coupled with other shafts of the reduction gear set to achieve a wider range of steering gear such as 360° rotation by controlling the gear ratio, and this may cause larger , but no cumulative error (i.e., the error increases with the angle of rotation).

Due to its simple structure and low cost, steering gear is used in many occasions, not only limited to model aircraft. It is also used in various robotic arms, robots, remote control cars, drones, smart homes, industrial automation and other fields. Various mechanical actions can be realized. There are also special high-torque and high-precision servos for use in fields with high precision requirements or fields that require large torque and large loads.

- +1 Like

- Add to Favorites

Recommend

- What Is Servo? How Does the Servo Work?

- Nidec Develops AC Servo Motor Equipped with Zignear® , the Location Detection Technology that Accommodates 17-bit Resolution, for the Industrial Robot Market

- How Is the Servo Controlled Through PWM?

- Nidec Launches a Lineup of VR Series Servo Motor Reducers for Food Machinery, Achieving a Torque of up to 80% of Standard Models

- DSPOWER Durable 20KG Class Semi-aluminum Frame Metal Tooth Servo DS-S020B Has a Maximum Torque of 28kgf.cm

- Choose Servo without Getting Lost: How to Choose the Right Servo According to the Specifications!

- Robot Servo: Key Elements Analysis and Selection Guide

- Nidec Launches New Models of FLEXWAVE Precision Control Reducers,Facilitating Servo Motor Installation

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.