Shindengen Developed Low Withstand Voltage Trench Structure MOSFET EETMOS Compact Package LF Series, Achieving both Lower Ron and Lower Qg

Shindengen Electric Manufacturing Co., Ltd. (Headquartered in Otemachi, Chiyoda-ku, Tokyo, Japan) has expanded its lineup with the development of the low withstand voltage trench structure MOSFET EETMOS LF Series, which is suited for use in various consumer and vehicle-mounted high current drive circuits, various power supply circuits, relay applications, and more.

Overview

In recent years, the automotive market has seen an increase in the number of ECU components installed as a result of the addition of new ECU such as safety devices including heads-up displays, the shift to electric automobiles, and automated driving, as well as information device-related components.

At the same time, there has also been an increasing focus on improving fuel consumption, and this has resulted in ever-increasing needs for more compact components aimed at making lighter weight ECU.

Shindengen was already engaged in the mass production of MOSFET which meet these needs. However, the development of the compact, high-current package LF Series utilizes a new package structure and achieves both lower Ron and lower Qg than conventional products.

*EETMOS is a registered trademark of Shindengen under Japanese law.

Features

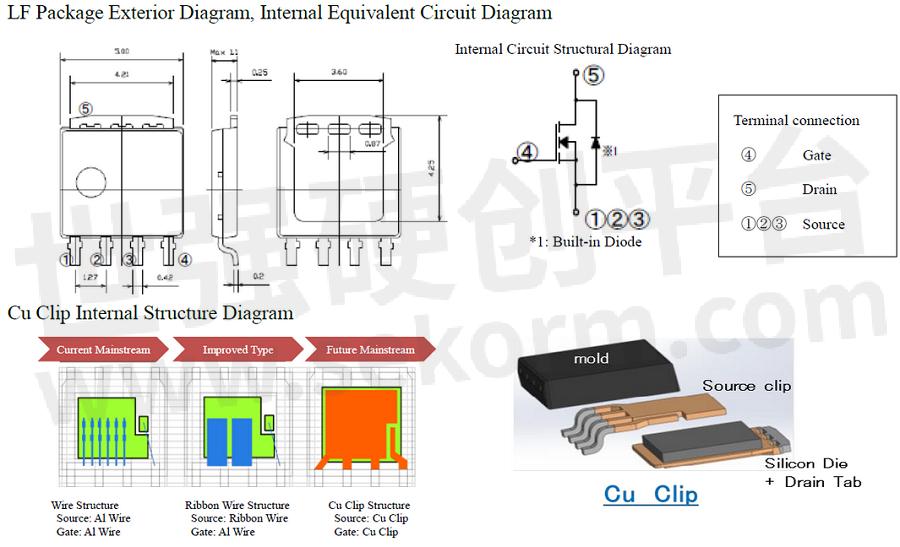

Cu clip internal structure allows for the achievement of low Ron and high current in a 5×6mm size compact package

Can be used as a replacement for SOP8 and HSON-type packages

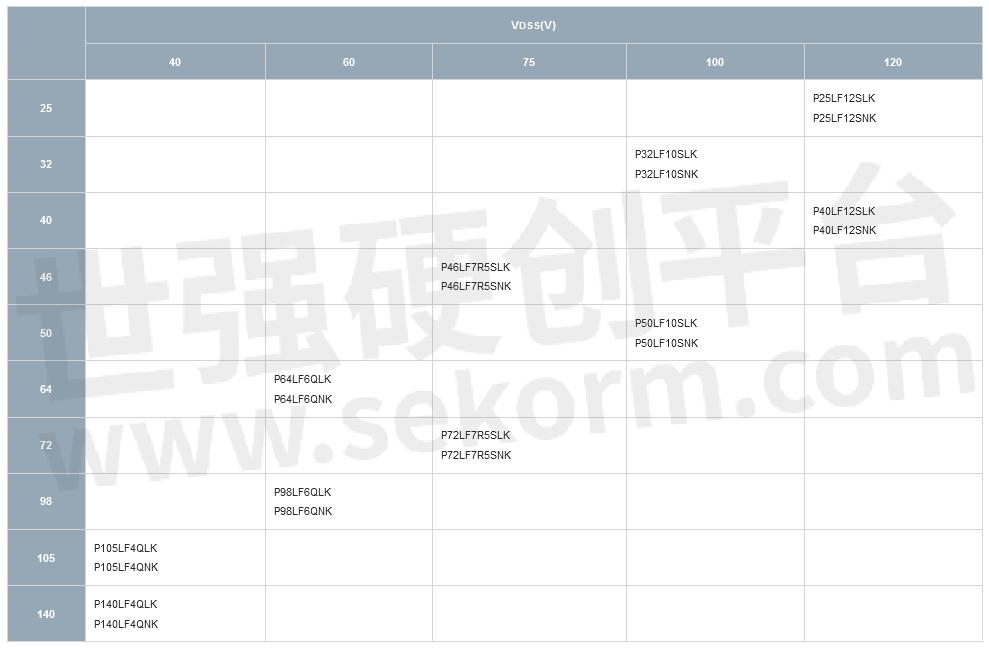

Covers a low withstand voltage to medium withstand voltage range of 40V to 120V

The use of a gull-wing shape for one side of the lead alleviates substrate stress while plating of the tip improves and provides high reliability

Tj=175℃ guaranteed

Based on the AEC-Q101 standard

Recommended Applications

Various motor drive circuits

Various power circuits

Relays, etc.

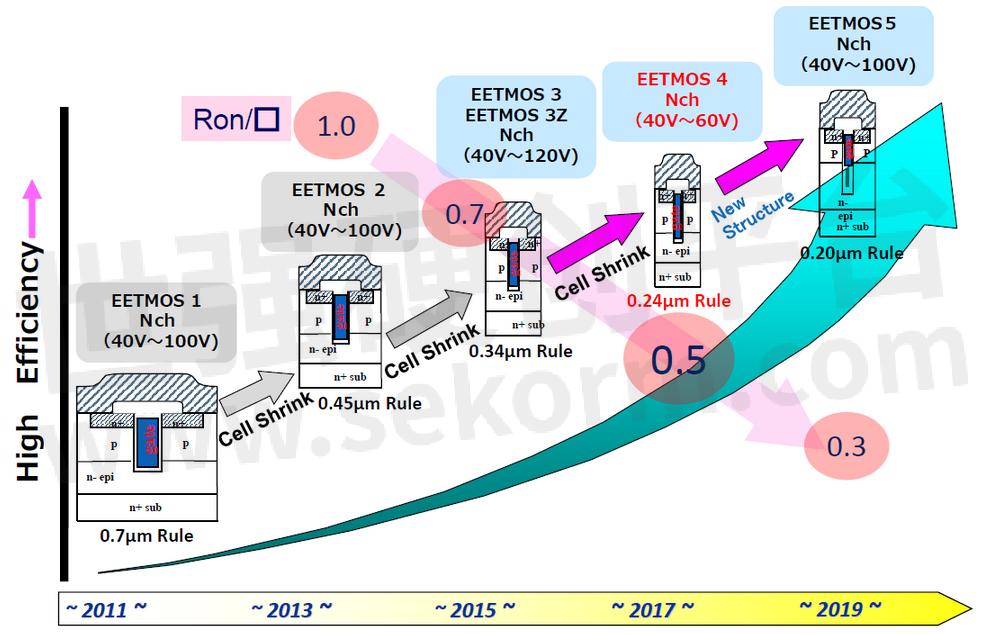

Development Roadmap

The 4th generation achieves a 50% reduction over the 2nd generation for performance index RDS(ON) *A

Product Diagram

(Can be used as a replacement for 5×6mm size packages.)

Samples, Mass Production Period

For Consumers

Samples: January 2018

Mass Production: May 2018

For vehicle installations

Samples: June 2018

Mass Production: December 2018

Production Factory

Higashine Shindengen Co., Ltd. etc

- +1 Like

- Add to Favorites

Recommend

- Shindengen Lineup Expansion of SMD Bridge Diode Rated Current 2A

- Shindengen Begins Mass Production of D5CE4S High Current Schottky Barrier Diode in Thinner JEITA SC-110 Package (CE)

- Shindengen New Product Information: Announcement About FR Package

- Shindengen Expanded Automotive Application Compatible Surge Absorption Power Zener Diode Series (TVS) Lineup for Vehicles, Reducing 50% Mounting Area

- Began 2kW PCU Mass Production for Two-wheel EV at Shindengen India in May 2023

- Shindengen‘s Dual MOSFET Contributes to Downsizing and Reduction in the number of Components for Various Types of Automotive ECU

- SHINDENGEN Expanded low VF Schottky Barrier Diode Lineups on TO-252 Equivalent

- Shindengen Launched a Control IC for Quasi Resonant Power Supplies which Can Reduce Standby Power by 38%

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.