3W, 6W, 10-12W 808nm VCSEL Chips with Power Conversion Efficiency up to 45%

In recent years, the market demand of laser processing has increased due to its inherent advantages and technological development, solid-state laser has widely drawn market attention due to its narrow pulse widths, high output energy, high peak power and good material absorption. Take the industrial field as an example, in addition to traditional laser marking, scribing, cutting, drilling, material removal, surface treatment and special material processing applications, the development of new technologies such as additive manufacturing, 3D printing, new display, UV laser marking, etc., further expand the application of solid-state laser.

semiconductor pumped solid-stable laser

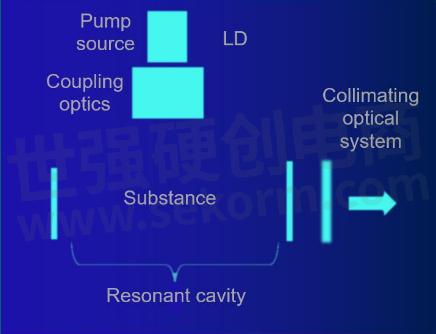

The 808nm laser diode is the core component of the pump source. The working principle of the pump source is to use a 808nm laser diode to pump by injecting current. Its working voltage and current are compatible with integrated circuit, so the threshold is monolithically integrated to obtain a high-speed modulated laser output. The laser performance of the laser requires uniform optical properties, good optical transparency and stable performance.

structure of a semiconductor pumped solid-stable laser

For semiconductor pumped solid-state lasers, the coupling of light is very important. There are two kinds of coupling, spatial coupling and fiber coupling. For spatial coupling, the pump source and the substrate can be separated so as to reduce the production costs and complexity of manufacturing process. For fiber coupling, a fusion splicer is required for welding of optical fibers, which increases manufacturing costs. Brightlaser’s 808nm VCSEL chip is suitable for spatial coupling type of 808nm high power diode pump solid state lasers, and the power level can be achieved up to hundreds of watts.

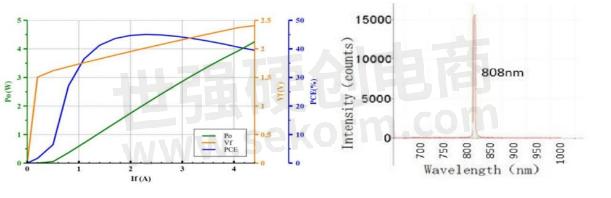

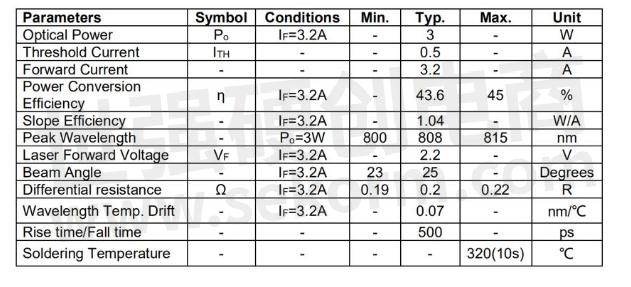

Compared with the traditional 808nm EEL pump source, VCSEL has better wavelength stability, the wavelength temperature coefficient is 0.07nm/°C while that of EEL is 0.25-0.3nm/°C. Besides, VCSEL has the characteristics of smaller divergence angle and round light spot, which is beneficial for collimation or focusing and simplifies the coupling link, it also helps to reduce costs and improve reliability. Furthermore, VCSEL has the advantages of high reliability, wide operating temperature range, and can better meet industrial requirements of lasers. The use of VCSEL pump laser sources is the trend of high-performance solid-state lasers and chip solid-state lasers.

808nm VCSEL chip 3.5x3.5mm package

At present, Brightlaser has 3W, 6W, 10-12W 808nm VCSEL Chips, with power conversion efficiency up to 45%, high reliability, high beam quality, long life, compact structure and low cost. As the core device of the semiconductor pumped solid-state laser, the demand of 808nm VCSEL chip is expected to be increased.

808nm 3W VCSEL chip LIV graph

Brightlaser 808nm VCSEL chip has a flat package, small size and light weight. It has the characteristics of small temperature influence, low wavelength drift as low as 0.07nm/°C, high output power, stable performance and long life of 50,000 hours.

808nm 3W VCSEL data table

The device based on Brightlaser 808nm VCSEL laser diode can be applied to 808nm high power vertical stacked semiconductor laser module, and it can also be used in laser medical and other applications. Brightlaser can also provide product customization services, such as vertical stacking of multiple laser array bars to form a high-power laser output. High-density laser array bar stacking technology is used with bar spacing being small to enable the module to obtain high-brightness laser output while maintaining a small size and high efficiency.

- +1 Like

- Add to Favorites

Recommend

- LEMON Photonics 808nm and 850nm VCSEL Chips Feature High Efficiency, High Reliability, and Excellent High-temperature Performance

- 808nm VCSEL Application: Semiconductor Laser Hair Removal

- High-performance Multi-junction VCSEL Laser Chips Boost Lidar and 3D Sensing

- Patented VCSEL Chips with Improved Divergence Angle of 11° and Peak Optical Powers over 20W in Pulse Mode

- Berxel Photonics demonstrates 106 Gbps VCSEL powered 800G transceiver with 100 meters transmission distance at CIOE 2023

- ROHM Develops a Novel VCSELED™ Infrared Light Source that Combines Features of VCSELs and LEDs

- Coherent Reports Significant Advancement in VCSEL Performance for Next-gen AI Networks

- VCSELs and How to Keep Them Cool--Laird Thermal Solutions‘ smaller and cost-effective OptoTEC™ MBX Series

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.