High-performance Multi-junction VCSEL Laser Chips Boost Lidar and 3D Sensing

According to Yole's "VCSEL - Technology and Market Trends 2022" report, multi-junction technology represents a new leap in the VCSEL industry, which will accelerate the application of VCSEL in the automotive field, high-performance VCSEL devices can be used as an ideal light source for 3D sensing applications such as lidar, and 5G networks increase the demand for high-speed optical modules, which have brought more market opportunities to VCSEL.

Advantages of multi-junction VCSEL over single-junction VCSEL

Compared to traditional single-junction VCSEL devices, multi-junction VCSEL connects multiple active regions in series through tunnel junctions in the same resonant cavity, resulting in a greater gain. As a result, Multi-junction VCSEL Laser Chips have a more compact size, higher power density, and electro-optical conversion efficiency (PCE). The increase in gain reduces the operating current of the multi-junction VCSEL, thereby reducing the power dissipation and cost of the drive circuit.

Illustration of multi-junction VCSEL. P-DBR/N-DBR: P and N-type distributed Bragg reflectors; MQW: Multiple quantum wells; TJ: Tunnel junction.

Advantages of multi-junction VCSEL over EEL

Unlike the side of EEL, it does not need to do much processing on the side, VCSEL is vertical surface light and only needs to be processed in batches according to the normal semiconductor processing process. Compared with EEL, the process is simpler and the cost is lower. According to Yole's statistics, the cost of EEL's post-processing process is more than double that of VCSEL. The increase in the number of junctions makes the luminous power of VCSEL increase rapidly, rapidly approaching EEL.

LEMON Photonics multi-junction VCSEL chip

Multi-junction VCSEL independently developed by LEMON Photonics

The optimization of the multi-junction VCSEL structure design independently developed by LEMON Photonics significantly improves the slope efficiency and output power density, and the current is significantly reduced, which improves the optical power while reducing the volume, providing power for demanding applications such as high-speed and high efficiency.

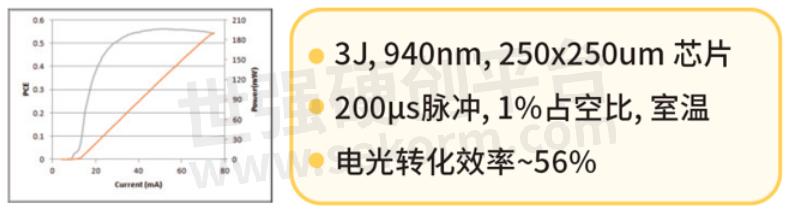

Multi-junction VCSELs enable faster rise times (dI/dt) to reach target peak power. Higher current and optical power densities can be achieved at narrower pulse widths. The experimental results inside the lemon photon show that the peak electro-optical conversion efficiency of the 940nm three-junction VCSEL of LEMON photonics is as high as 56%.

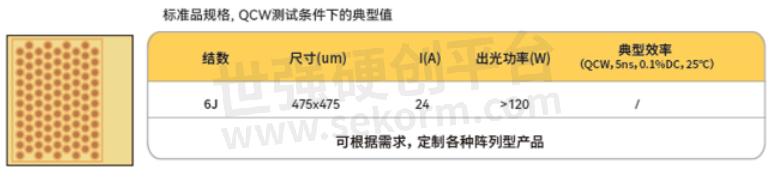

List of 940nm multi-junction VCSEL models

The six-junction 905nm VCSEL has a 0.1% duty cycle at 25°C and a 5ns pulsed optical power greater than 120W, and meets the requirements of automotive-grade VCSEL applications.

six-junction 905nm VCSEL

All 905nm and 940nm multi-junction VCSEL series products are based on the LEMON Photonics team's approximately 20 years of laser semiconductor experience, offering advantages in efficiency, scalability, and reliability.

Multi-junction VCSEL optimization for next-generation lidar and industrial 3D sensing

Multi-junction VCSEL laser arrays are one of the next-generation solutions for LEMON Photonics to optimize automotive lidar and industrial 3D sensing applications. Its small body size, high power density, and 905nm 120W multi-junction VCSEL are very suitable for short to long-range LiDAR solutions. Automotive-grade VCSEL products can be easily upgraded with existing mechanical LiDAR solutions or configured as addressable, solid-state scanning LiDAR laser light sources.

In addition to providing high-quality, cost-effective solutions for automotive and industrial environments. At present, multi-junction VCSEL is also widely used in industrial three-dimensional sensing, optical communication, 3D face recognition technology, intelligent robots, mechanical LiDAR, solid-state electronic scanning LiDAR, and other fields.

- +1 Like

- Add to Favorites

Recommend

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.