Integrated Cladding Light Strippers for Improving Beam Quality and the Accuracy of Optical Measurements

Reducing unwanted stray signals (interference) in the cladding results in less downtime and significant improvements to measurement accuracy in optical metrology. In the examples of applications given below, for fiber/diode lasers, combiners and splices, plus material processing, 3D printing, and spectroscopy, LEONI give you a quick overview of the advantages of integrated cladding light strippers.

When light is coupled into optical fibers, unwanted stray signals often arise in the cladding, producing heat that can often damage the optical cables or additional noise that is capable of distorting the measurement. Over-irradiation of the fiber core in lamp systems (and for diode lasers in particular), for example, or excessive bending of the fibers can result in light propagating outside the light-transmitting core. This is especially relevant when using high-performance diode lasers, since their powerful output combined with unwanted cladding modes can lead to damage in the optical system. Typical applications here include combiners for pumped lasers, LIDAR systems and pumped lasers, splices, laser material processing, and spectroscopy – which we’d like to tell you a little more about here.

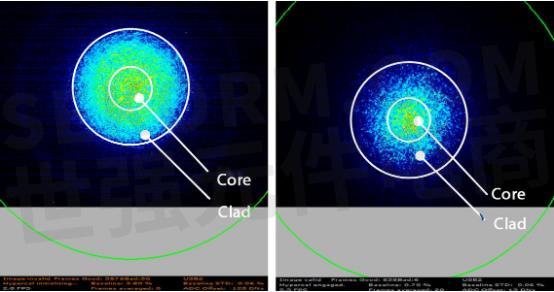

These issues are particularly common in fiber lengths of less than 100 m, as opportunities for cladding mode attenuation are very limited here. The use of integrated cladding light strippers here is very advantageous, resulting in significant improvements to beam quality and beam diameter at the fiber exit point (see figure 1). Furthermore, this results in lower temperatures for the optical cable, which in turn ensures less incidence of damage, as well as a much lower level of noise in optical instruments.

Fig.1. Left side: fiber optic cable without cladding light stripper, optical power is transported in the cladding; right side: with cladding light stripper, optical power is transported only in the core

Use with fiber lasers

Standard fiber lasers now available on the market utilize the principle of the optical pumping of an active doped fiber pathway. The diagram in figure 2 shows a laser system of this kind.

The high level of energy to be pumped into this system is a technical barrier to guiding the optical power downstream of the laser resonator in the core. This endangers the downstream beam forming optics, resulting in a worsening of beam quality.

After integrating our cladding light stripper, temperature conditions improve significantly for the fiber optic cables and other components. During operation, fiber-optical beam guiding has a demonstrably lower temperature (<40 °C instead of >100 °C beforehand) and therefore a much higher life expectancy. This ensures a long lifetime for the optical components used, as well as a consistently high beam quality.

Fig.2: Laser beam delivery of diodes in pump fibers

Use with combiners for pumped lasers

Where high-powered lasers are used to pump an active fiber, the pump laser setup may require a combination of multiple laser diodes in order to provide the required output. Due to the differences in laser beam geometry from an edge-emitting laser diode to the fiber optic cable, over-irradiation of the fiber core can occur, resulting in high thermal stress to the fiber combiner. Cladding light strippers can be deployed to drastically reduce this thermal load, which in turn avoids burn-off affecting the combiner’s adhesives and fiber coatings. This helps you protect your sensitive pumped laser system with combiners from unnecessary damage and increase its long-term stability correspondingly. This, in turn, will have a very positive effect on a total cost of ownership (TCO) analysis of your system.

Use with splices

In technical terms, modern fusion splicing equipment offers a wide range of options for splicing fiber optic cables of various diameters and numerical apertures. At the transition points created by splicing, the different diameters and numerical apertures can permit light to be coupled into the cladding of the optical fiber. This cladding mode effect results in the creation of high thermal loads at the splicing points, which can potentially destroy the optical fiber. This means our customers who use high-power lasers are faced with a serious problem. In real-world applications, it was found that the lifetime of fiber optic cables was unsatisfactory, due to thermal effects at the splicing points: the fibers burned out after a short period of use.

The use of a cladding light stripper on the splices allows the excess power to radiate out of the fiber cladding. Even in fiber laser applications whose power is of the order of several hundred watts, for example, cladding modes of tens of watts can be safely stripped from the cladding. The housing surrounding the cladding light stripper is also efficient at preventing leakage of laser radiation and works as a thermal sink to dissipate the excess energy. This gives you the freedom to position the cladding light stripper exactly as you wish, so as to optimize your overall system in terms of thermal loads. One way to do this is to identify and select the most suitable place in your setup, for example.

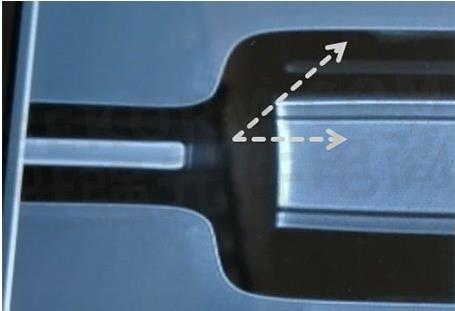

Fig.3: Splicing of two fibers with different diameters and numerical aperture, arrows indicate potential cladding modes

Use in laser material processing

In the field of laser material processing, our customers are increasingly reporting problems they are having with fibers burning out during material processing. After investigating these phenomena, we found that reflecting surfaces on the material to be processed were the cause of these issues – such as reflectance on metallic and powder-coated surfaces on the components to be manufactured.

The high laser power involved in processing is only partially absorbed. The result is uncontrolled back-reflections into the fibers.

In the customer’s application, the use of a cladding light stripper helped to ensure that the laser power fed back into the fibers could be radiated out in a controlled way. Even with the laser system in continuous operation, we identified no further relevant heating in the fibers.

Use in spectroscopy

In spectroscopy applications, problems often occur due to the very low level of optical power that is available. This makes the signal-to-noise ratio also very low, which causes problems when attempting to produce an accurate analysis of the measurement results. As a result, cladding modes can lead to unwanted superimpositions that adversely affect signal quality.

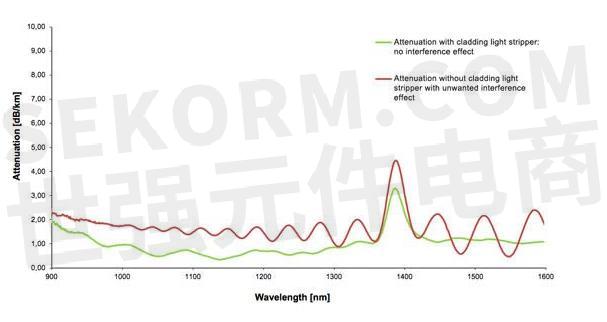

Significant improvements can be achieved in these results by using a cladding light stripper. Figure 4 offers an example of wavelength-dependent attenuation in an optical fiber contrasted with the attenuation obtained when using an integrated cladding light stripper. Even at low power levels in optical metrology projects, measurement precision is enhanced because only the signal actually relevant and required for the measurement is transmitted in the optical cable.

Fig.4: Spectral attenuation: AS300/330IRPIT Measured length: 268m

Integrated cladding mode product portfolio

Integrated cladding light strippers are available as an assembly option for our laser cables, and fiber bundle assemblies, and especially as:

Industrial laser assemblies

Fiber bundle assemblies

High-performance arrays

LIDAR units

We can offer you integrated cladding light strippers for all of our fiber types, coatings, with and without buffers, and in all typical materials (incl. PI and high-temperature jackets), and all standard connector formats. Our integrated cladding light strippers are also available without additives such as adhesives or acids, so as to meet the highest standards (such as no outgassing, biocompatibility, etc.), while also offering excellent long-term stability.

- +1 Like

- Add to Favorites

Recommend

- Smiths Interconnect Deliver A New Highly Integrated Multi-channel Subsystem

- EPC Has Introduced A 100V, 65A Integrated Circuit Chipset Designed for 48V DC-DC Conversion

- 8610 Battery Pack Integrated Testbed for Testing New Energy Vehicle Battery Systems and Subparts | Chroma

- EPC2152 GaN Integrated Power Stage – Redefining Power Conversion

- World‘s first TPMS integrated by OEMs with Bluetooth® Technology

- EPC Announces New eGaN Transistors and Integrated Circuits for Demanding Space Applications

- Based on TOF, Benewake‘s Lidar Can Be Integrated into the Robot and And Realize Obstacle Avoidance

- EPC‘s ePower Stage EPC2152 Integrated Circuit Named Finalist in Prestigious Elektra Awards

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.